Method for preparing Ti2CTx from fuse salt

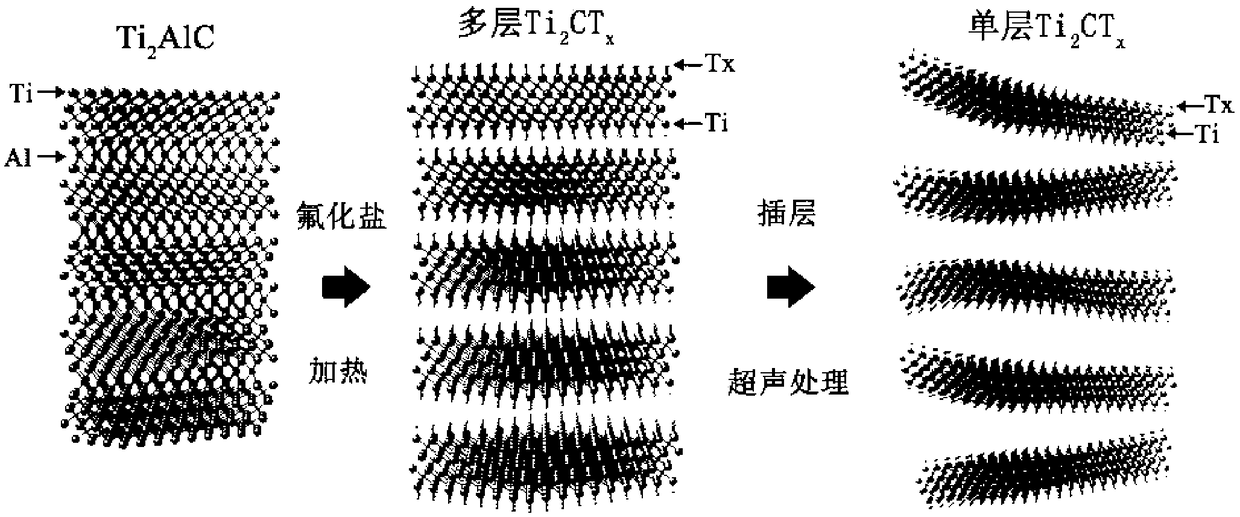

A technology of molten salt and potassium fluoride is applied in the field of preparation of new two-dimensional transition metal carbide Ti2CTx to achieve the effects of improving specific capacity and adsorption capacity, simple operation and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

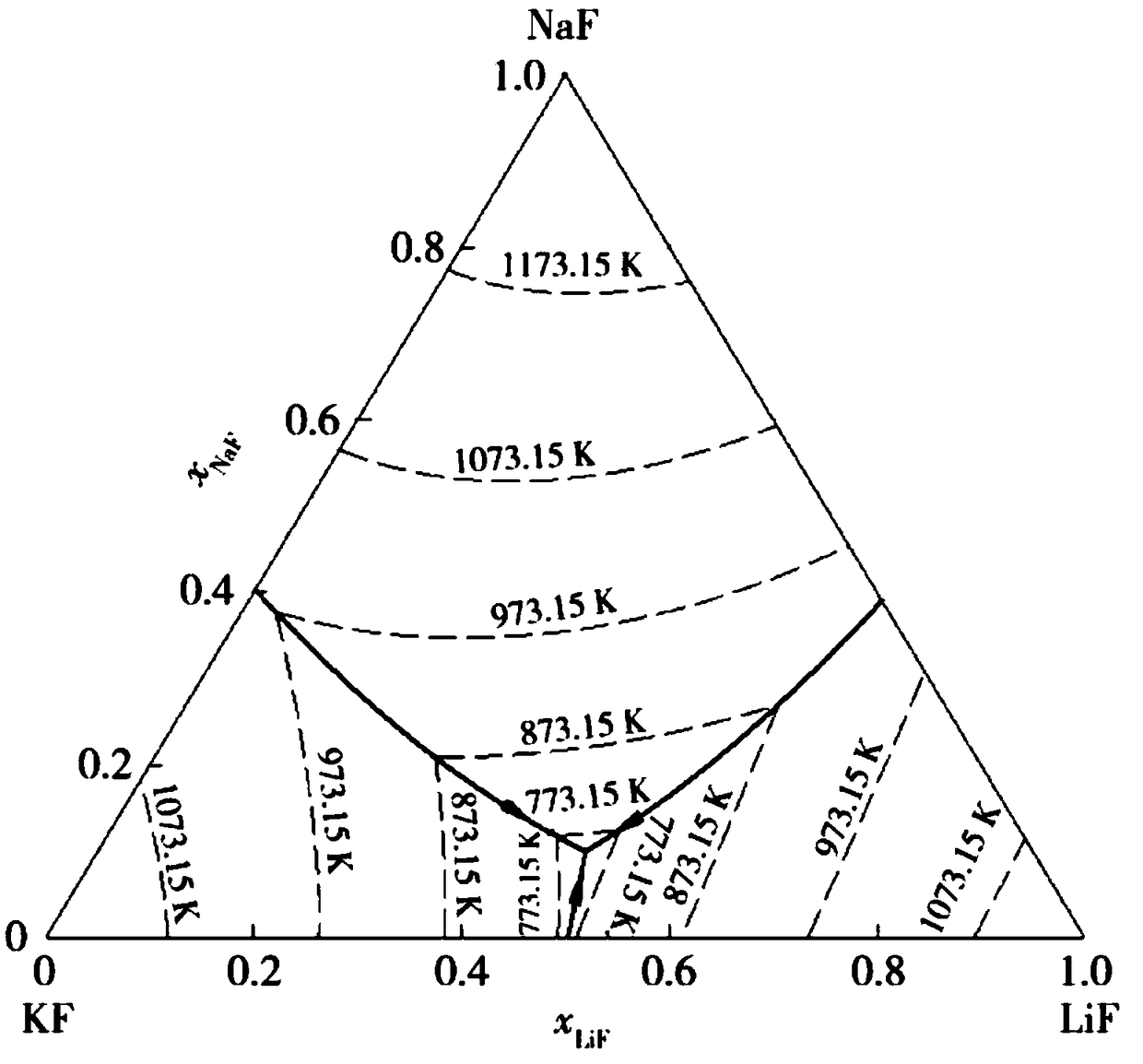

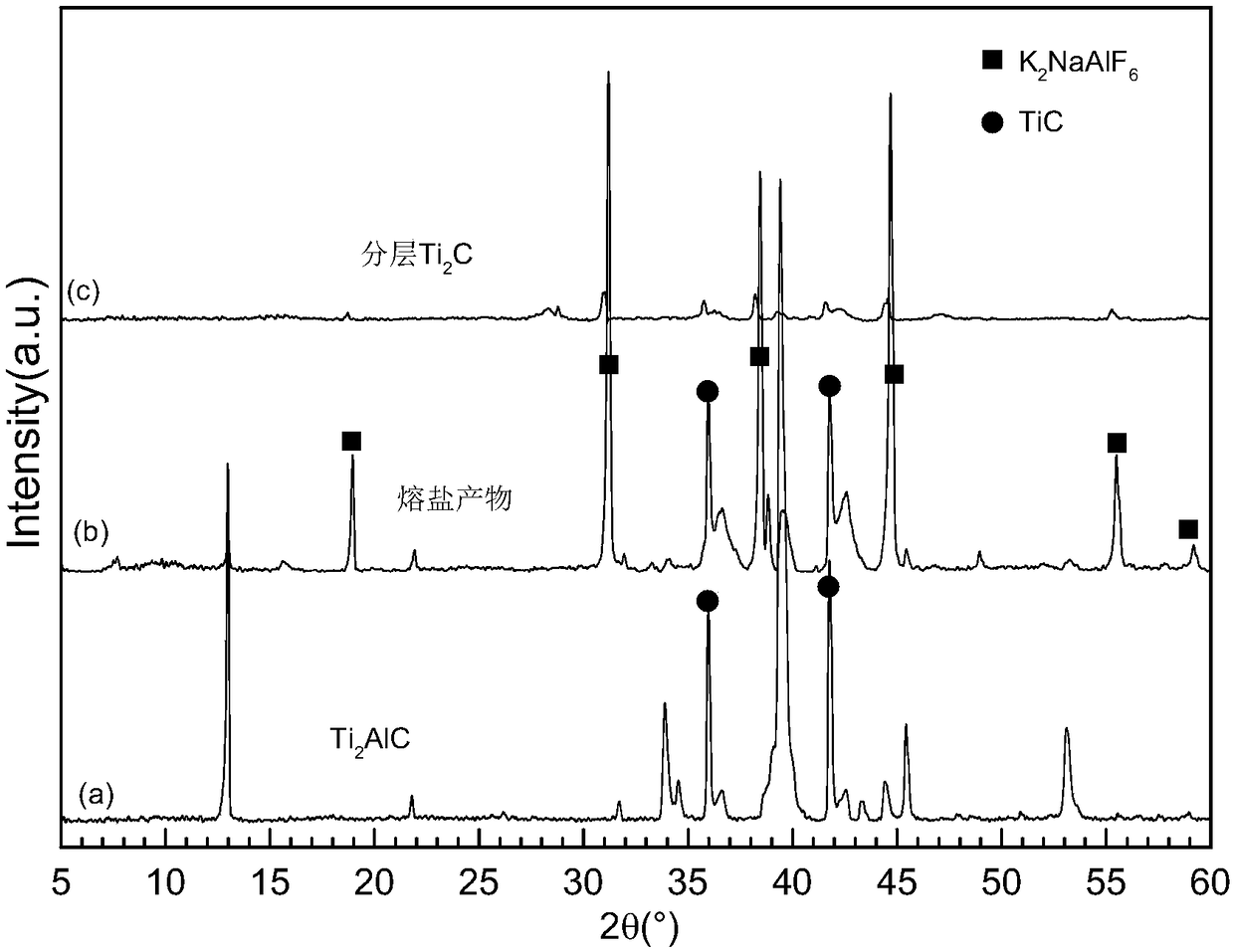

[0026] Ti 2 The mass ratio of the four raw materials of AlC powder, potassium fluoride, lithium fluoride and sodium fluoride is Ti 2 AlC:KF:LiF:NaF=1:0.59:0.29:0.12; mix evenly, put it into a tube furnace for calcination, and use argon protection. The heating rate is 10°C / min, the temperature is 550°C, and the temperature is kept for 50 minutes to obtain a molten salt product.

[0027] Take 1 gram of the molten salt product and add it to 10 milliliters of 4mol / L sulfuric acid solution and stir for 1 hour. After the reaction, add deionized water and repeatedly centrifuge and wash until the supernatant pH ≈ 7. Pour off the supernatant to obtain a precipitate; take 0.3 grams Mix the precipitate with 6 ml of ammonia water and stir for 1 hour, add deionized water and wash repeatedly by centrifugation for 4 to 5 times, after adding deionized water for the last time, sonicate for 60 minutes, and centrifuge at 6000rpm for 25 minutes, and collect the supernatant suspension with a filt...

Embodiment 2

[0029] Ti 2 The mass ratio of the four raw materials of AlC powder, potassium fluoride, lithium fluoride and sodium fluoride is Ti 2 AlC:KF:LiF:NaF=1:0.59:0.22:0.19; mix well, put into tube furnace for calcination. The heating rate is 10°C / min, the temperature is 650°C, and the temperature is kept for 40 minutes to obtain the molten salt product.

[0030] Take 1 gram of the molten salt product and add it to 10 milliliters of 4mol / L sulfuric acid solution and stir for 1 hour. After the reaction, add deionized water and repeatedly centrifuge and wash until the supernatant pH ≈ 7. Pour off the supernatant to obtain a precipitate; take 0.3 grams Mix the precipitate with 6 ml of ammonia water and stir for 1 hour, add deionized water to wash repeatedly by centrifugation for 4 to 5 times, add deionized water for the last time, and then sonicate for 60 minutes, and centrifuge at 6000rpm for 30 minutes, and collect the supernatant suspension with a filter membrane Particles in the la...

Embodiment 3

[0032] Ti 2 The mass ratio of the four raw materials of AlC powder, potassium fluoride, lithium fluoride and sodium fluoride is Ti 2 AlC:KF:NaF=1:0.675:0:0.325 (that is, there is no lithium fluoride, only Ti 2 AlC powder, potassium fluoride, sodium fluoride three raw materials); mix evenly, put into tube furnace for calcination. The heating rate is 10°C / min, the temperature is 850°C, and the temperature is kept for 30 minutes to obtain the molten salt product.

[0033] Take 1 gram of the molten salt product and add it to 10 milliliters of 4mol / L sulfuric acid solution and stir for 1 hour. After the reaction, add deionized water and repeatedly centrifuge and wash until the supernatant pH ≈ 7. Pour off the supernatant to obtain a precipitate; take 0.3 grams Mix the precipitate with 6 ml of ammonia water and stir for 1 hour, add deionized water and wash repeatedly by centrifugation for 4 to 5 times, after adding deionized water for the last time, sonicate for 60 minutes, and ce...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap