Anti-floating anchor rod pile and construction method

An anti-floating anchor and construction method technology, which is applied in construction, anti-floating anchor engineering design, and anti-floating anchor pile construction fields, can solve the problems of large cement consumption, hole formation and collapse, and avoid hole collapse, The effect of strengthening the overall stability and stabilizing the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to facilitate those of ordinary skill in the art to understand and implement the present invention, the present invention will be described in further detail below in conjunction with the examples. It should be understood that the implementation examples described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

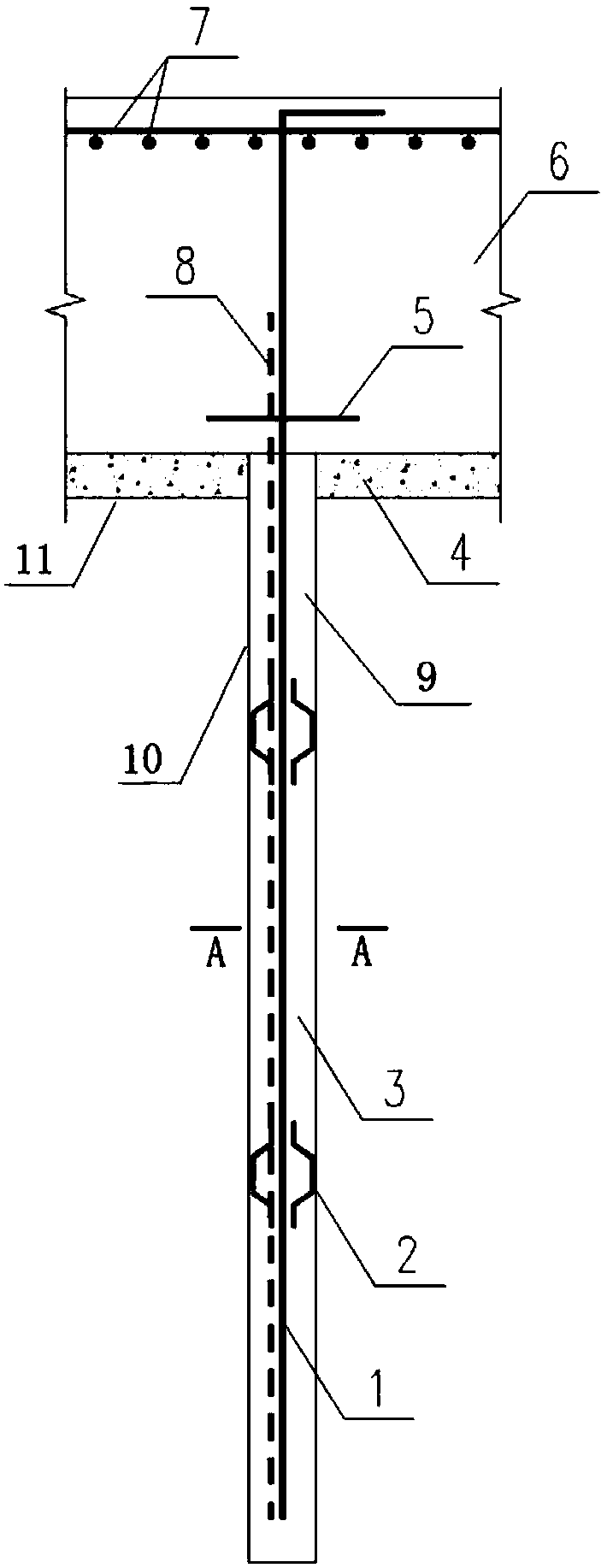

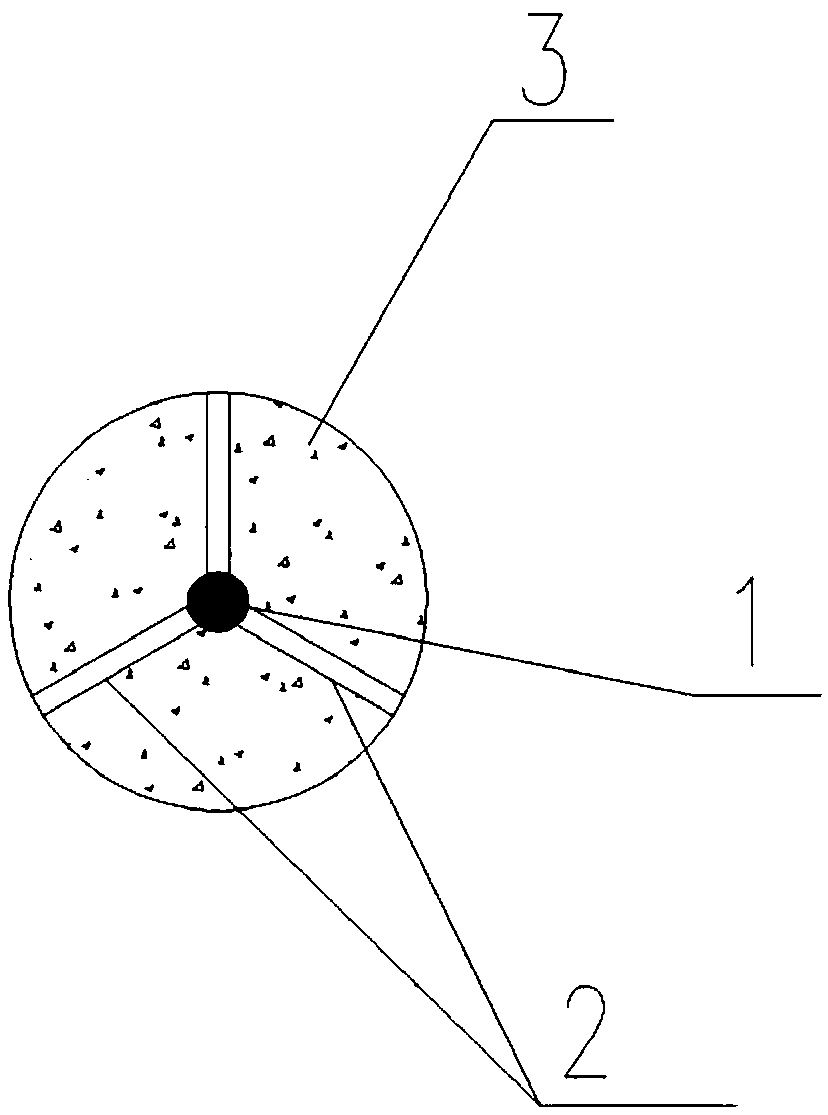

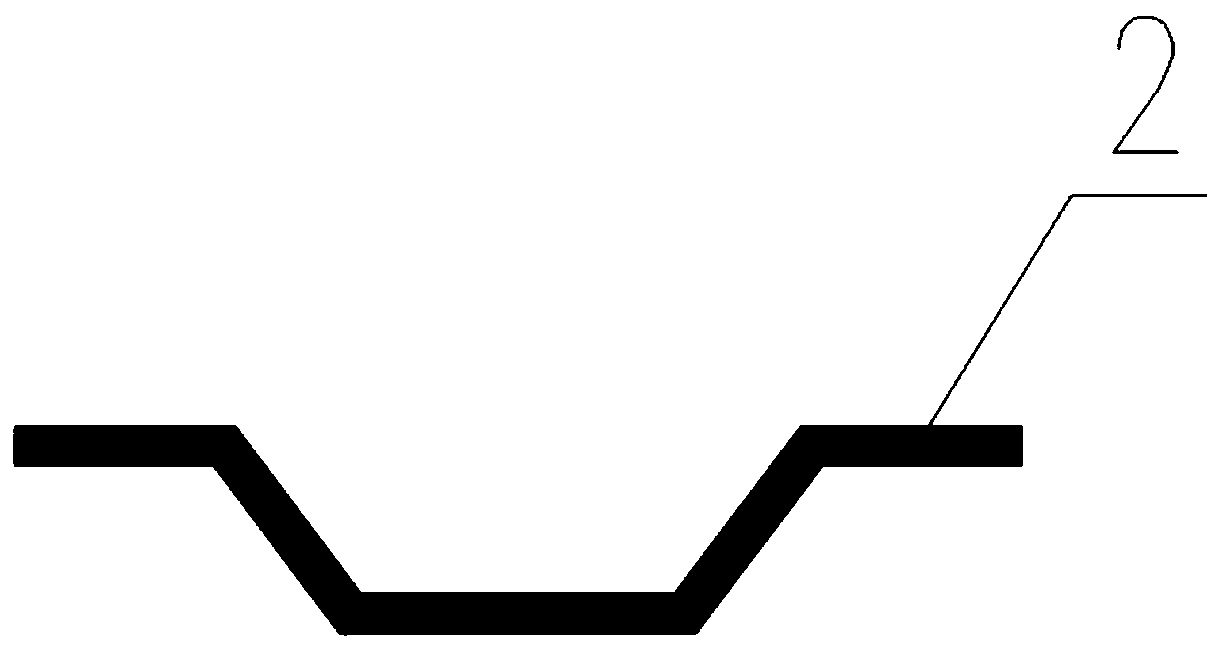

[0033] Such as Figure 1~Figure 3 As shown, an anti-floating anchor pile device includes pile body 9, anchor bar steel bar 1, positioning bracket 2, graded crushed stone 3, foundation cushion 4, steel plate water-stop collar 5, concrete foundation 6, foundation surface Layer steel mesh sheet 7. In this embodiment, the pile body 9 has a diameter of 180mm and a length of 8m.

[0034] The pile body 9 is arranged in the borehole 10, the pile body 9 is a crushed stone concrete pile body, the anchor rod steel bar 1 is arranged in the pile body 9, the foundation 11 at the top of the bor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com