No-negative-pressure water supply system

A water supply system, no negative pressure technology, applied in the water supply pipeline system, water supply main pipeline, water supply tank configuration, etc., can solve the problems of noise generation, inability to perform shock absorption, inability to remotely monitor the operation of equipment, etc., to reduce noise Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

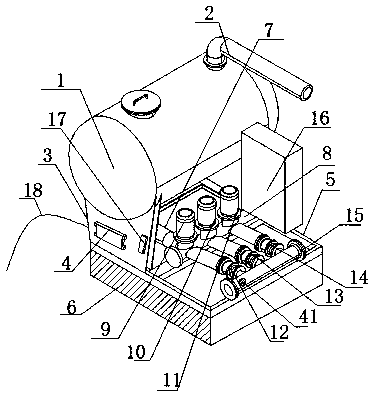

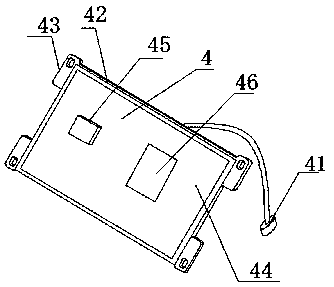

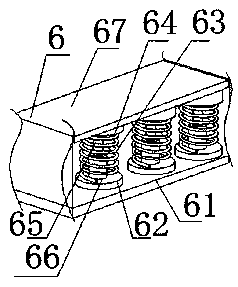

[0027] In this technical solution:

[0028] Monitoring device 4, shock absorbing device 6, flow sensor 41, frame 42, connection block 43, placement plate 44, microprocessor 45, GPRS transmission module 46, bottom plate 61, negative plate 62, compression spring 63, top plate 64, vertical rod 65, column 66 and stainless steel layer 67 contain substantive innovative components for the present invention.

[0029] Buffer tank 1, water inlet pipe 2, support frame 3, underframe 5, water outlet pipe 7, connecting pipe 8, first water pump 9, second water pump 10, third water pump 11, first drain valve 12, second drain valve 13 , the third drain valve 14, the water pipe 15, the control cabinet 16, the control switch 17 and the power line 18 are the indispensable connecting components for realizing the technical solution of the present invention.

[0030] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be furthe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com