Push rod mechanism with automatic retraction function

A technology of push rod mechanism and function, which is applied in the field of push rod mechanism, can solve the problems that the missing gear cannot be the driving force of the rack, the contact between the gear and the rack is discontinuous, and the noise is large, so that it is not easy to jam the teeth, the structure is simple, low noise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

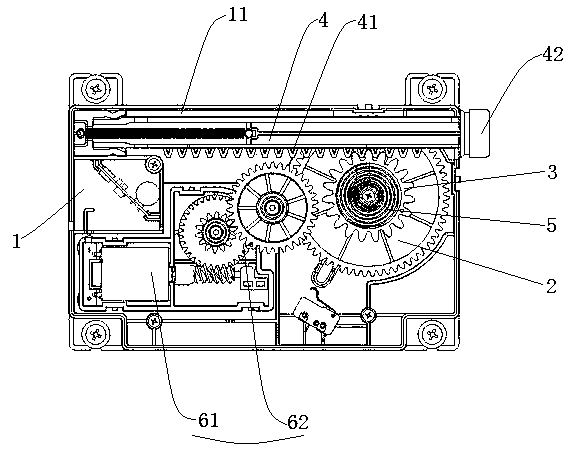

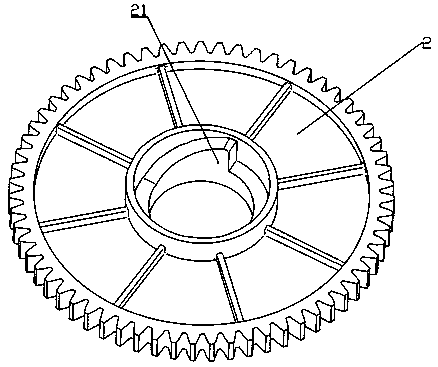

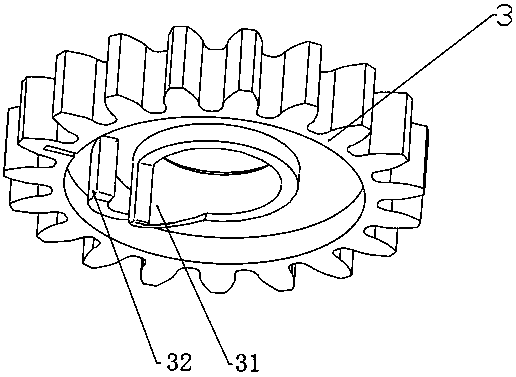

[0032] refer to Figure 1~9 , a push rod mechanism with automatic retraction function, including a housing 1, a driving wheel 2, a driving gear 3, a push rod 4 and an installation shaft 5, the installation shaft 5 is fixedly installed on the housing 1, and the The driving wheel 2 and the driving gear 3 are successively installed on the mounting shaft 5 from bottom to top. The housing 1 can be provided with a slideway 11 matching the push rod 4, and the push rod 4 is installed in the slideway 11, so that the push rod 4 can expand and contract in the slideway of the housing 1, wherein the push rod 4 can only Do telescopic movement in sliding without other movements such as lifting or rotating. The push rod 4 is provided with a rack 41, and the drive gear 3 is engaged with the rack 41, so that the drive gear 3 drives the push rod 4 to expand and contract longitudinally. The drive gear 3 can move axially along the installation shaft 5 on the installation shaft 5, so as to realiz...

Embodiment 2

[0044] refer to Figure 10 , the main structure of this embodiment is the same as that of Embodiment 1, the difference lies in the structure of the driving gear 3, and the connection mode between the driving wheel 2 and the driving gear 3, as follows:

[0045] The lower side of the drive gear 3 is provided with only one screw table, that is, the third screw table 33. The width of the third screw table 33 is wider, which is about the sum of the width of the first screw table 51 and the first card table 21. . The lower side of the third helical table 33 is opposite to the upper side of the first helical table 51, and the third helical table 33 can slide relative to the first helical table 51; the rear side of the third helical table 33 is in contact with The front sides of the first clamping platform 21 are oppositely arranged, and the driving wheel 2 drives the driving gear 3 to rotate through the first clamping platform 21 pushing the third screw platform 33 . The height of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com