Transmission shaft overturning prevention positive displacement motor with overload protection

An overload protection, screw drilling tool technology, applied in drilling equipment, earth-moving drilling, driving device for drilling in wellbore, etc. The effect of reducing risks and making the transmission mechanism safe and reliable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

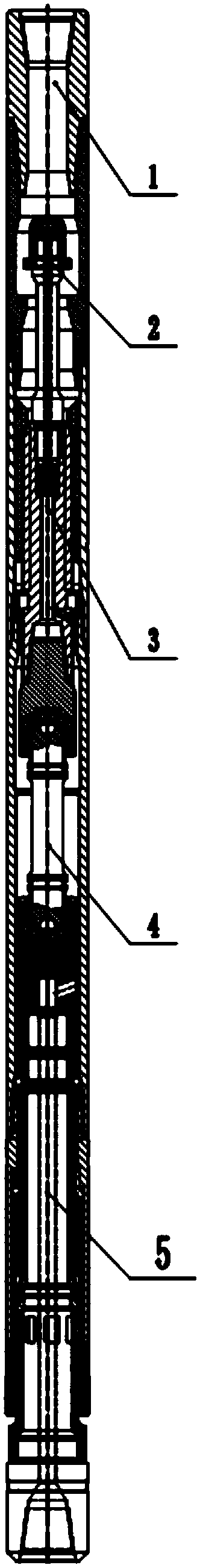

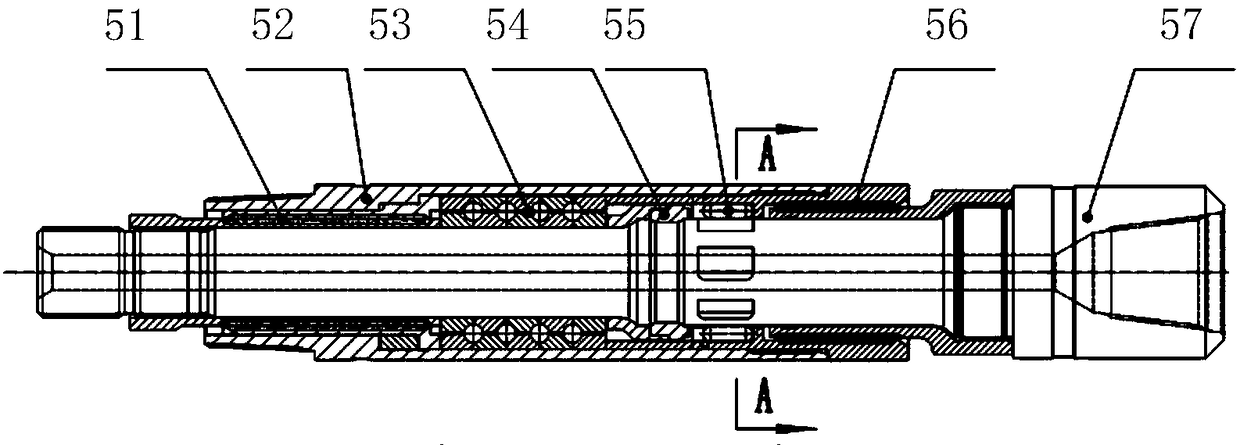

[0013] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments. Such as figure 1 As shown in the figure, a screw drilling tool with overload protection to prevent reverse transmission shaft, including bypass valve assembly 1, anti-drop assembly 2, motor assembly 3 for overload protection, cardan shaft assembly 4 and The anti-reversing drive shaft assembly 5; the overload protection motor assembly limits the maximum pressure drop output by the motor, thereby limiting the maximum torque output by the motor, thereby protecting the transmission mechanism.

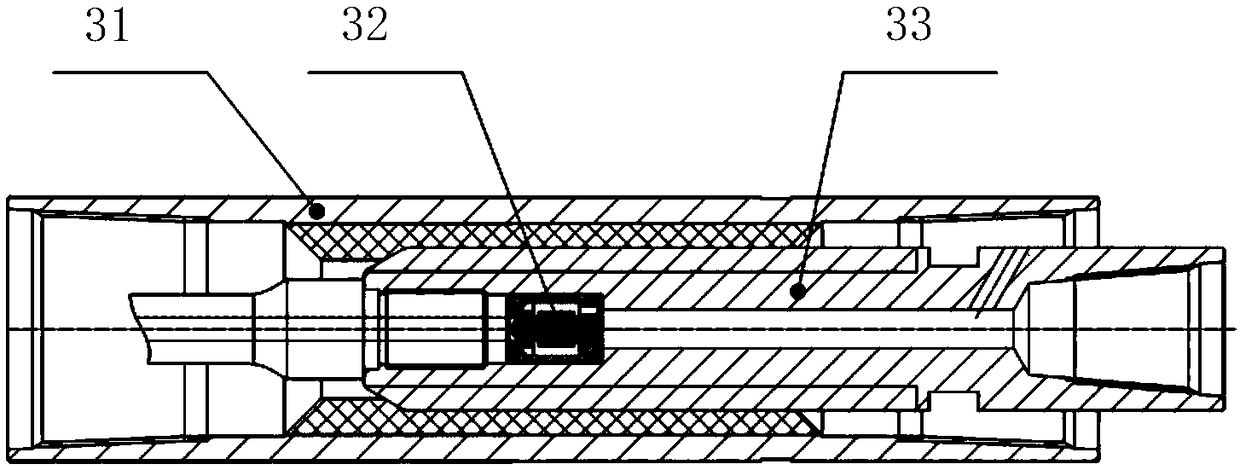

[0014] Such as figure 2 As shown, the overload protection motor assembly includes a stator 31, a hollow rotor 32 and a high-pressure one-way relief valve 33, the hollow rotor is assembled inside the stator, and the high-pressure one-way relief valve is installed inside the hollow rotor The high-pressure single relief...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com