Tubular motor reduction gearbox with protection mechanism

A technology for tubular motors and protective mechanisms, applied in the direction of electromechanical devices, electrical components, structural connections, etc., can solve the problems of easily damaged motors, jamming between gears, lack of motor protection, etc., achieve long service life, protect motors, and facilitate installation and labor-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings.

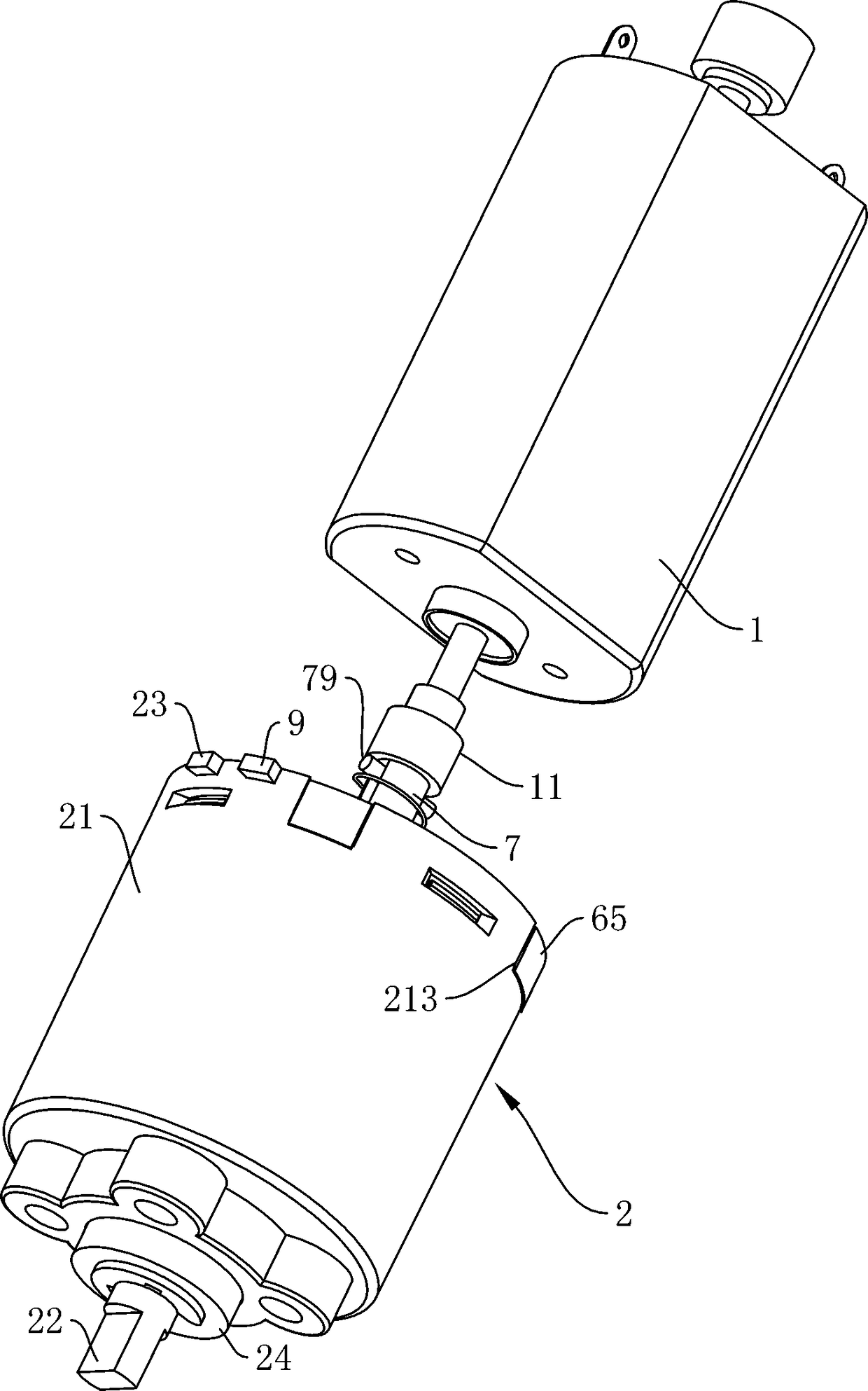

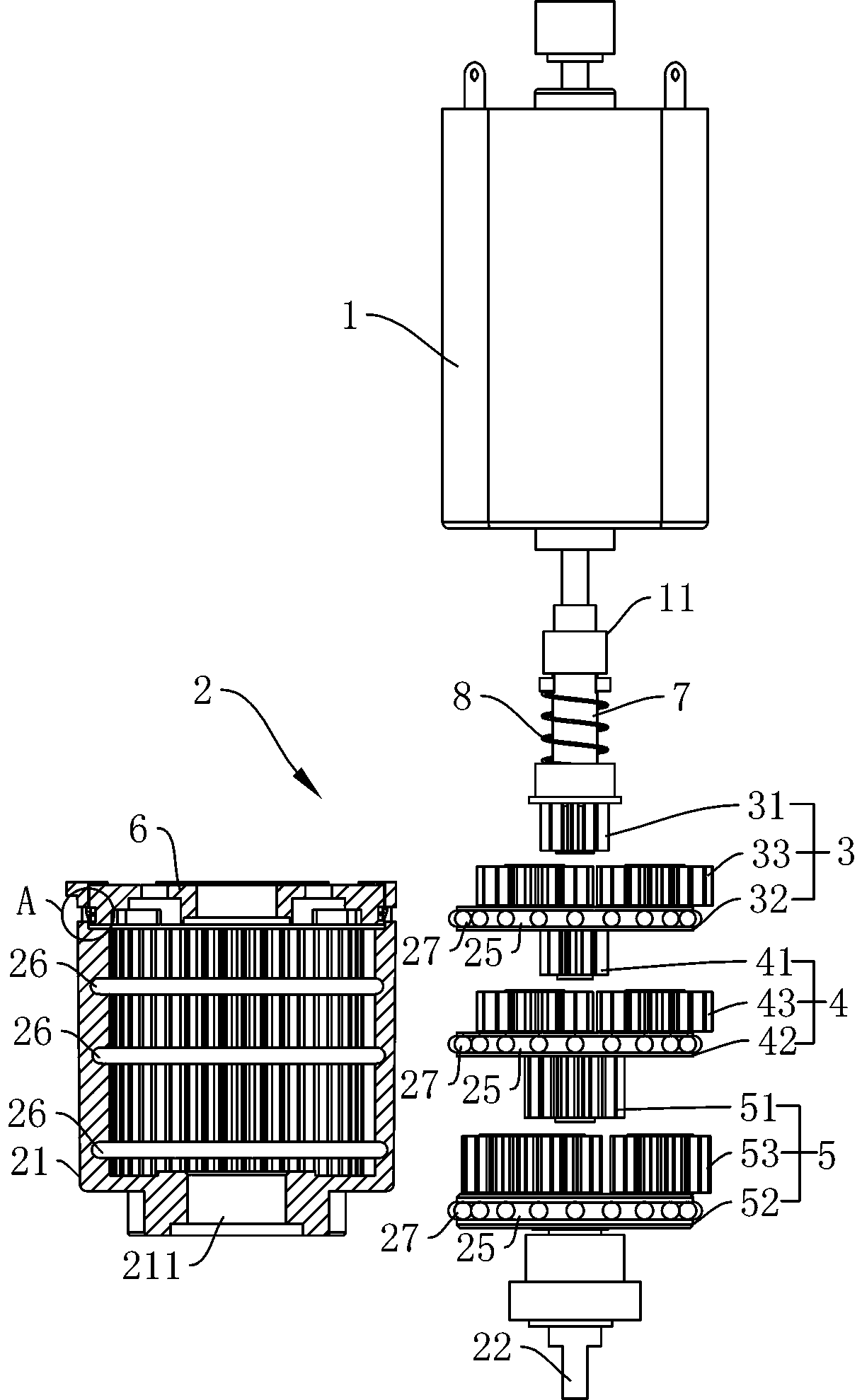

[0033] A tubular motor gearbox with a protective mechanism, such as figure 1 As shown, it includes a motor 1 and a reduction box 2. The reduction box 2 includes a connecting shaft 7 and an output shaft 22. A connecting sleeve 11 is arranged on the rotating shaft of the motor 1. The connecting shaft 7 is connected to the rotating shaft of the motor 1 through the connecting sleeve 11. The output shaft 22 is connected with external equipment. When using the tubular motor reducer, the motor 1 is started, the reducer 2 is driven by the motor 1 to realize the transmission, and the external equipment connected to the output shaft 22 is rotated.

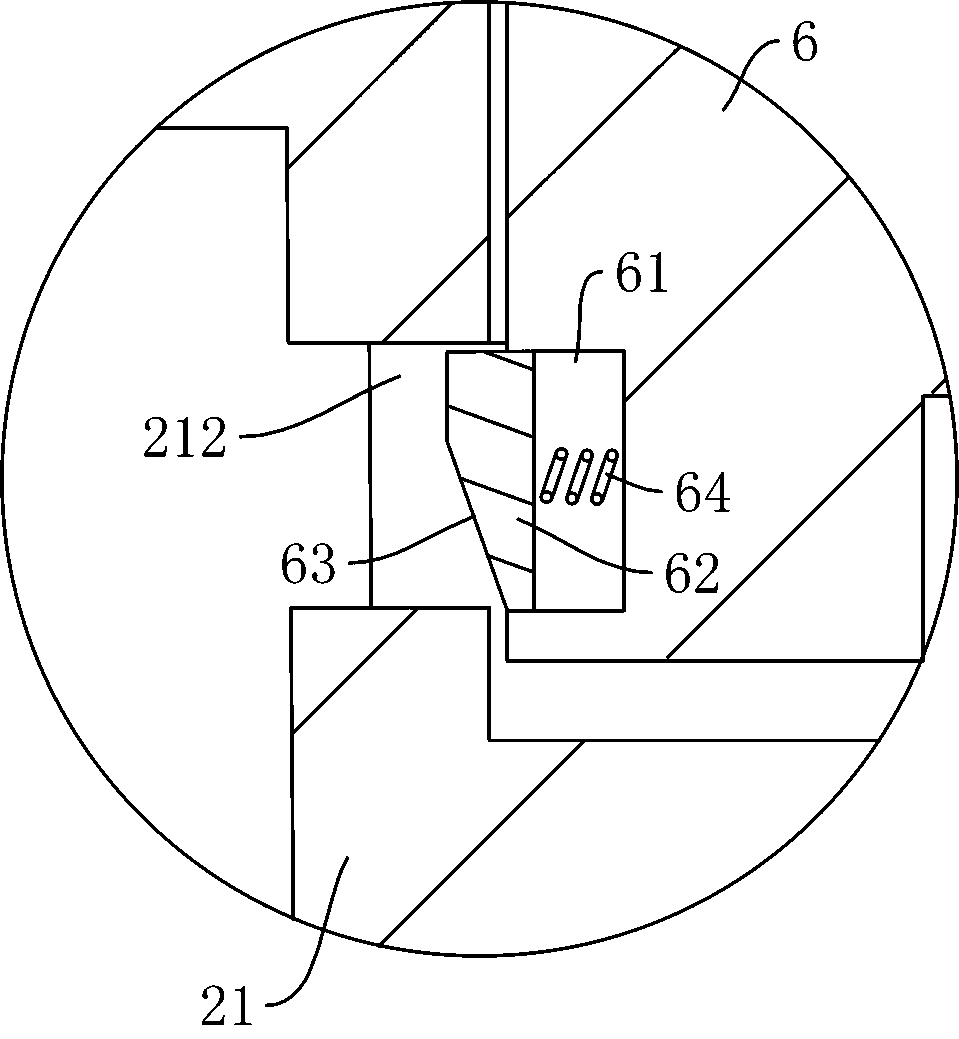

[0034] Such as figure 1 and figure 2 As shown, the reduction box 2 includes an inner gear sleeve 21, and the outer wall of the inner gear sleeve 21 is provided with a pressure sensor 9 and a control switch 23. The pressure sensor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com