Test device for online testing ball screw pair friction torque and axial load

A technology of ball screw pair and friction torque, which is applied in the direction of measuring devices, testing of mechanical components, testing of machine/structural components, etc., to achieve the effects of improving test accuracy, eliminating influence, and avoiding assembly errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0015] The invention relates to a test device for online testing of the friction torque and axial load of a ball screw pair, which is used to study the relationship between the axial load, pretightening force and friction torque under the working state of the ball screw pair, and further The friction and wear characteristics and accuracy retention of the ball screw pair under different loads were studied.

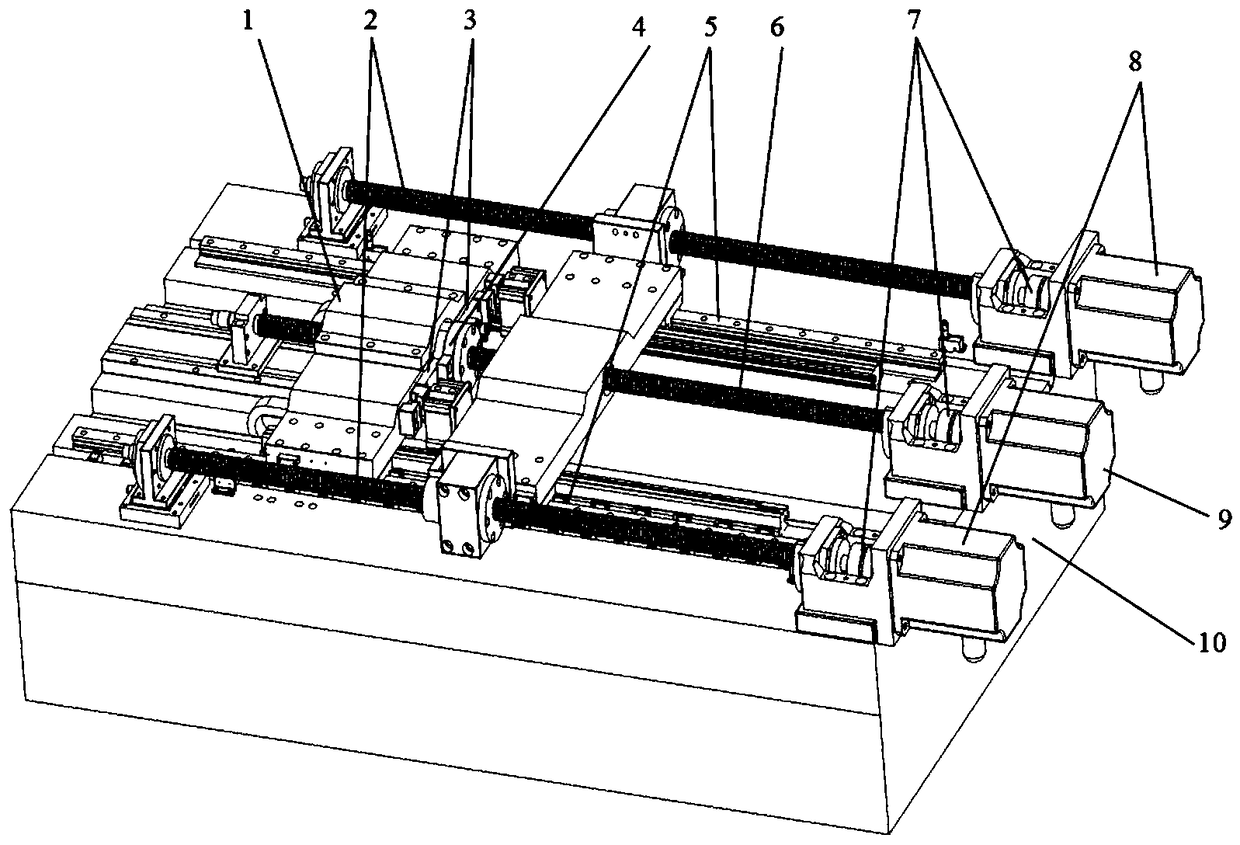

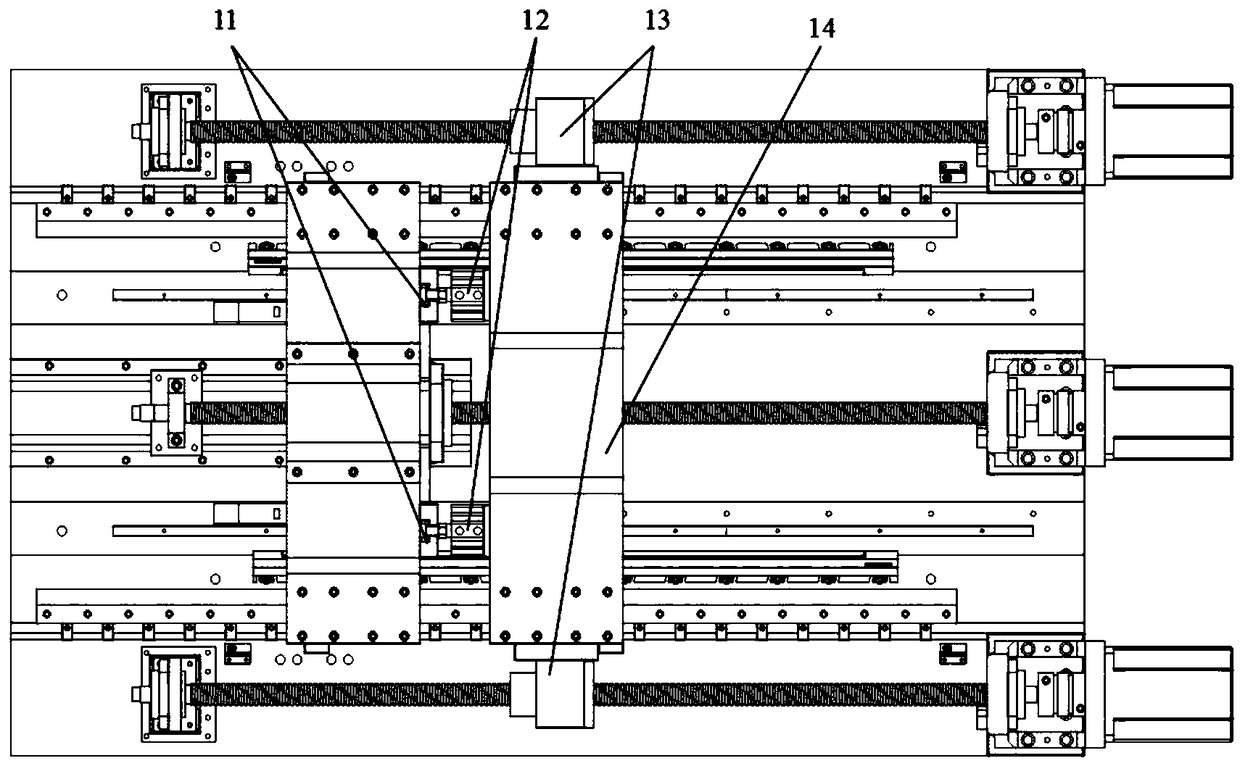

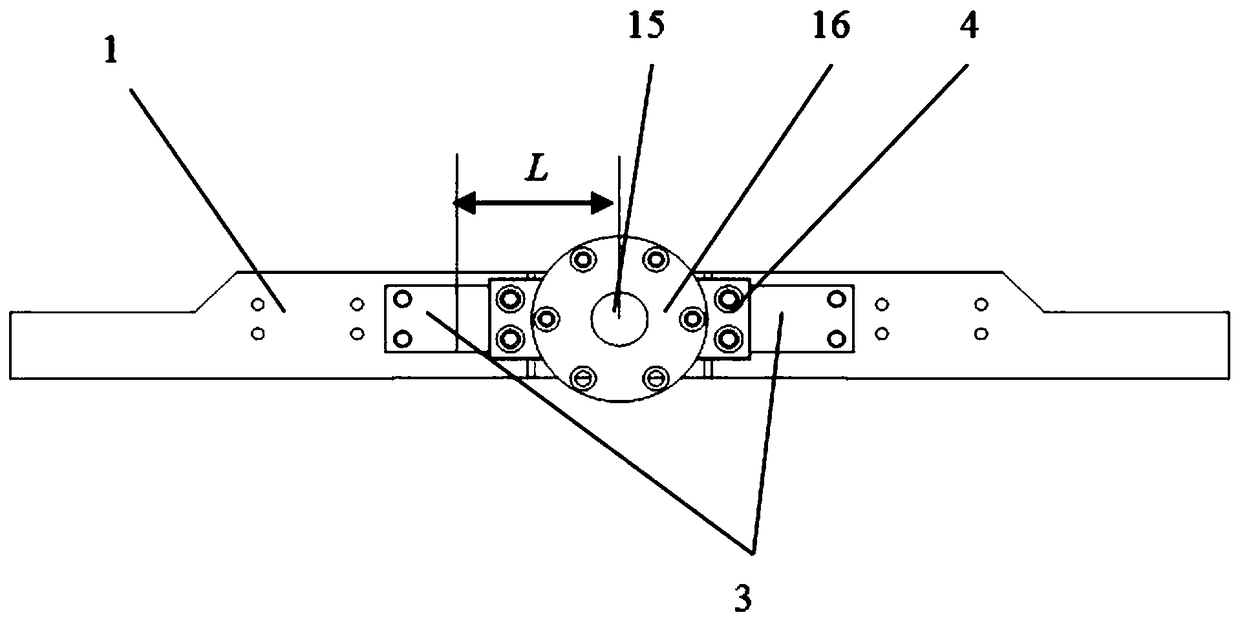

[0016] In order to achieve the above purpose, the technical solution adopted by the present invention is a test device for online testing of friction torque and axial load of the ball screw pair. The test device includes: main workbench (1), auxiliary ball screw pair (2 ), two-dimensional force sensor (3), main nut seat (4), linear rolling guide pair (5), main ball screw pair (6), coupling (7), auxiliary servo motor (8), main servo Motor (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com