A miniaturized high temperature resistant high dynamic pressure sensor

A pressure sensor, high dynamic technology, applied in the direction of measuring fluid pressure, measuring fluid pressure through electromagnetic components, instruments, etc., can solve the problems of blockade and high cost of sensors, achieve inhibition of element diffusion, excellent resistance to thermoplastic deformation, and solve high temperature failure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

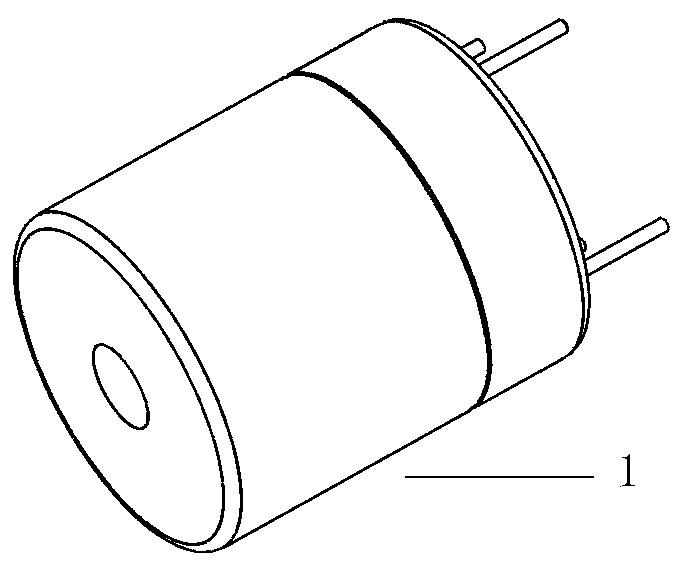

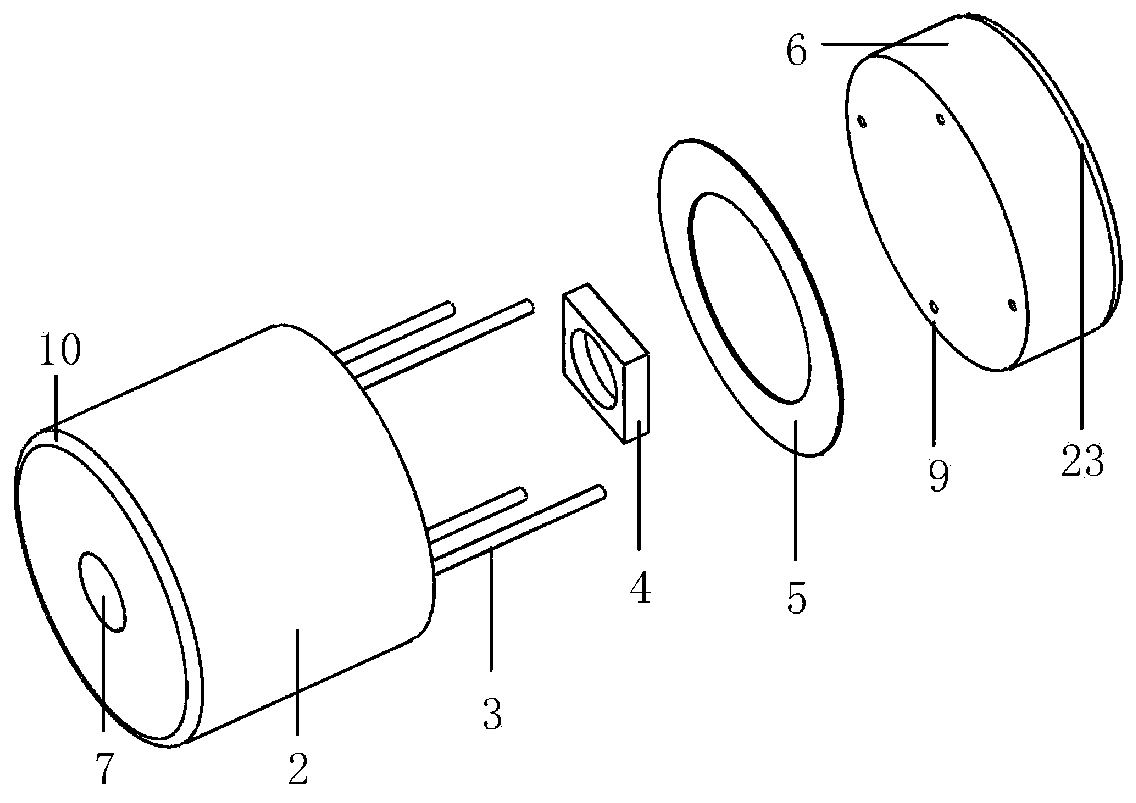

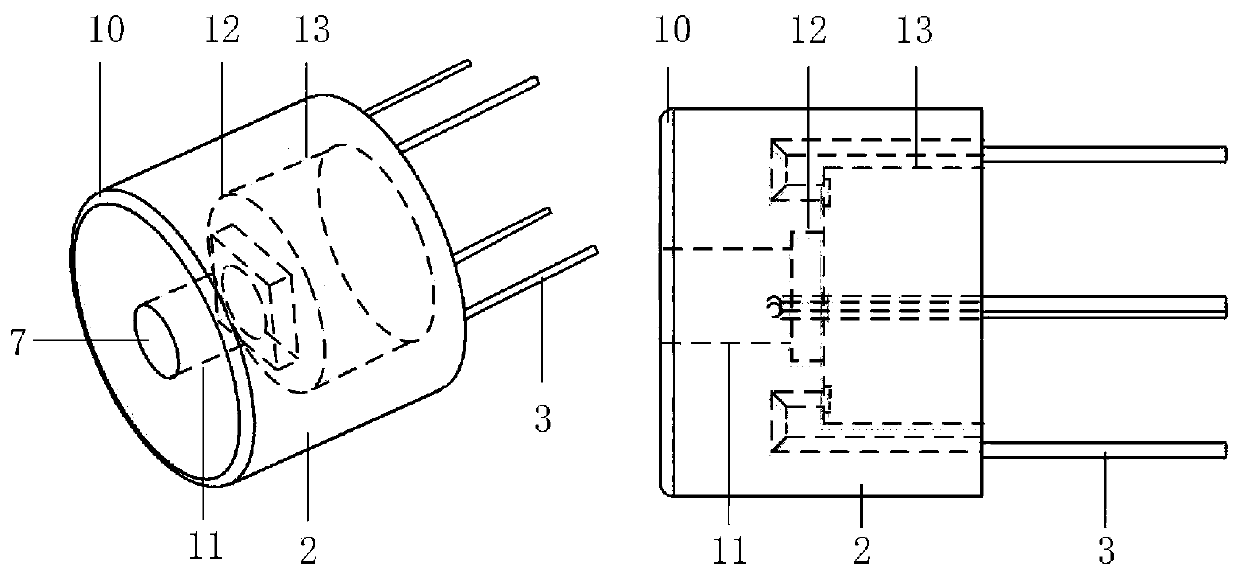

[0026] refer to figure 1 and figure 2 , a miniaturized high temperature resistant high dynamic pressure sensor 1, including a sensor probe 2, a sensor chip 4 is installed inside the sensor probe 2, the sensor chip 4 is fixed in the sensor probe 2 through a high temperature resistant ceramic glue 5, and the sensor probe 2 is connected with The metal tungsten wire 3 passes through the sealing plate 6, and the sealing plate 6 and the sensor probe 2 are connected together. The diameter of the packaged sensor 1 is 6 mm, and the length from the front end of the probe 2 to the rear end of the sealing plate 6 is 10 mm. The sealing plate 6 is in the shape of a round cake, and there are four tungsten wire pin through holes 9 in the sealing plate 6 , and the rear end surface of the sealing plate 6 has a rounded corner structure 23 .

[0027] The mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com