A post-processing method for 3D printing high-temperature structural ceramics

A 3D printing and ceramic technology, which is applied in the field of 3D printing applications, can solve the problems such as the loss of structural collapse strength of 3D printed products, and achieve the effects of solving the loss of structural collapse strength, improving structural strength, and fast printing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

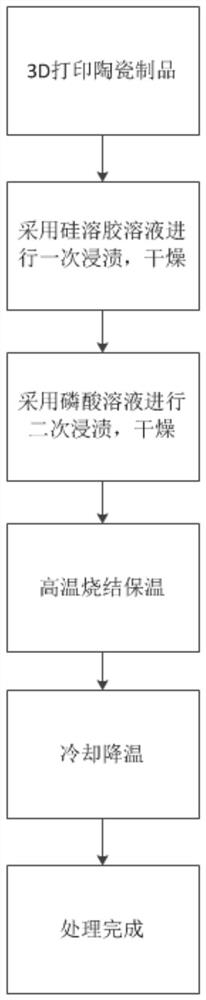

Method used

Image

Examples

Embodiment 1

[0038] S1: Soak the silica ceramic product formed by 3D printing with adhesive jetting in a silica sol solution with a solid phase mass percentage of 20% for 10 minutes, take it out and dry it at 100-120°C;

[0039] S2: Soak the sample dried in the above steps in a phosphoric acid solution with a concentration of 45% by mass for 10 minutes, take it out and dry it at 100-120°C;

[0040] S3: The dried sample in the above steps was kept at a temperature of 1680° C. for 1 hour, and cooled naturally to obtain the treated 3D printed silica ceramics.

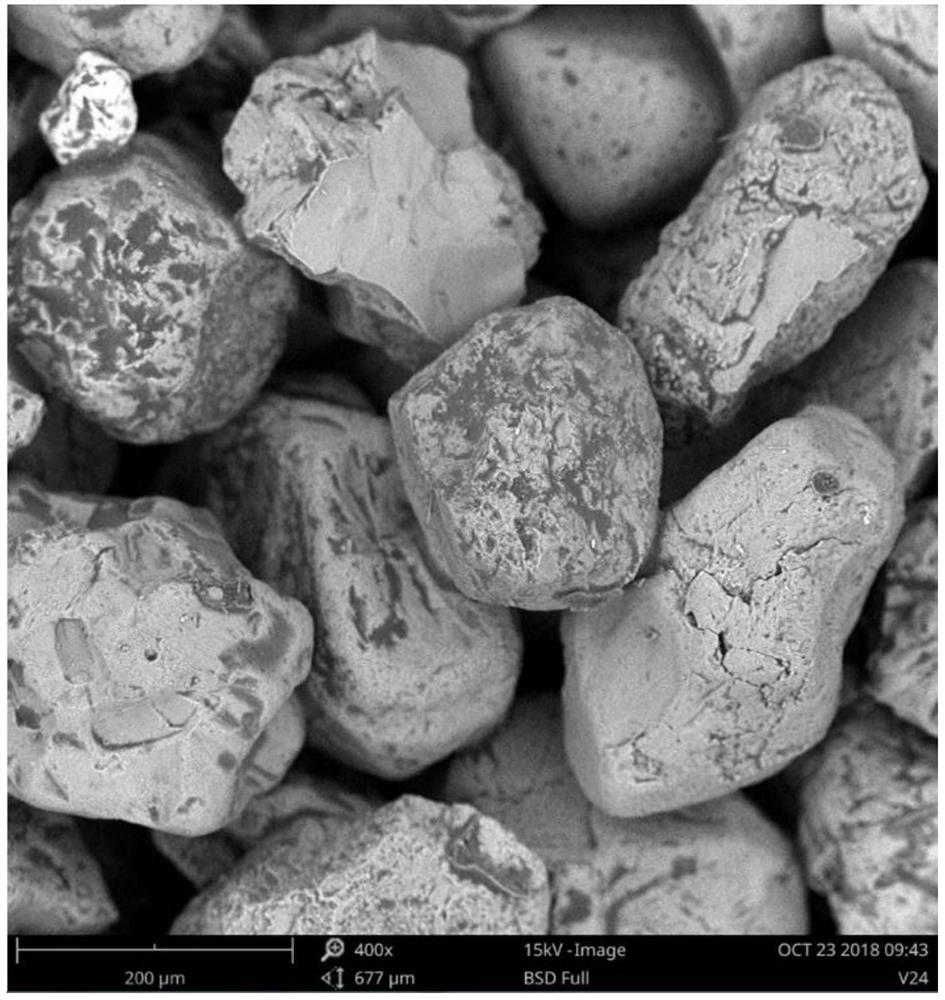

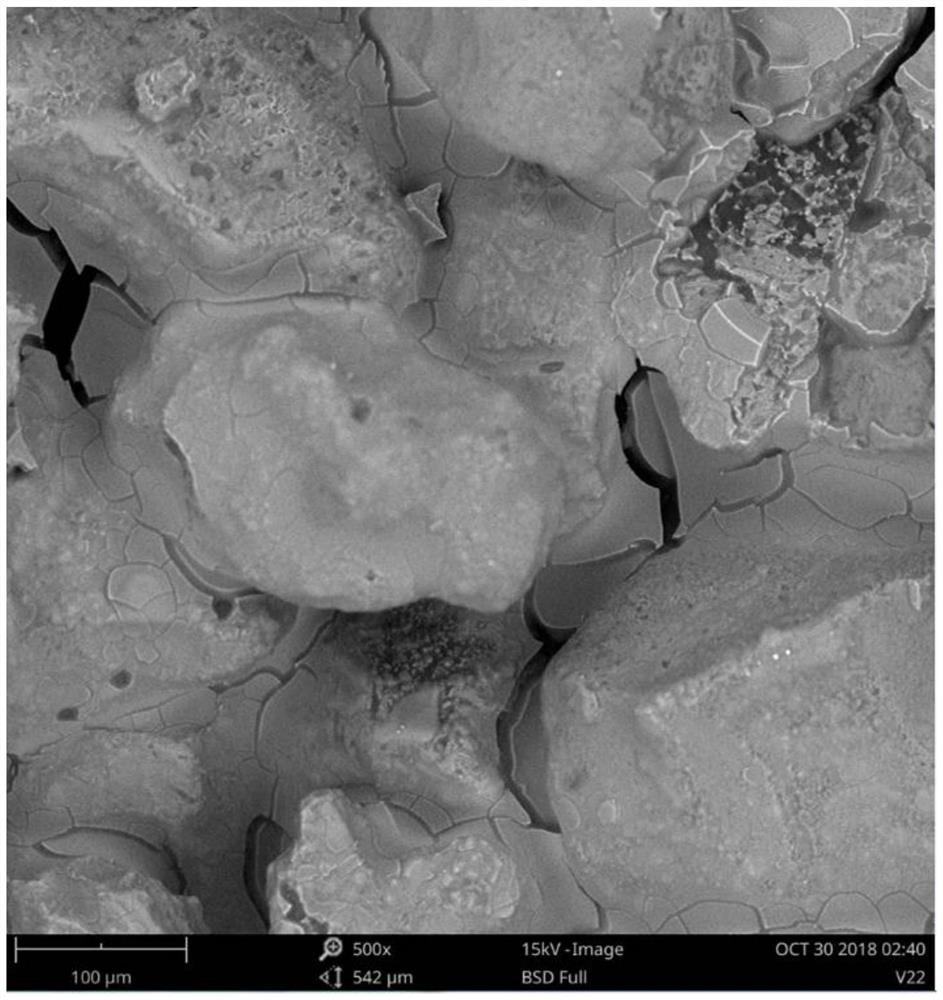

[0041] Such as figure 2 Shown: This picture is the scanning electron microscope picture of untreated 3D printed silica ceramics. It can be seen from the picture that there are many gaps on the surface, and the cementation effect between the particles is not good; image 3 Shown: This picture is a scanning electron microscope image of 3D printed silica ceramics after secondary impregnation. It can be seen from the figure that the void...

Embodiment 2

[0043] S1: Soak the silica ceramic product formed by 3D printing with adhesive jetting in a silica sol solution with a solid phase mass percentage of 20% for 10 minutes, take it out and dry it at 100-120°C;

[0044] S2: Soak the sample dried in the above steps in a phosphoric acid solution with a concentration of 60% by mass for 10 minutes, take it out and dry it at 110°C;

[0045]S3: The dried samples in the above steps were kept at a temperature of 1680° C. for 1.5 hours, and cooled naturally to obtain processed 3D printed silica ceramics.

[0046] The 3D printed silica products without post-treatment will completely collapse at high temperature, and the compressive strength of the 3D printed silica ceramic products treated by the method of this embodiment is 2.98MPa.

Embodiment 3

[0048] S1: Soak the silica ceramic product formed by 3D printing with adhesive jetting in a silica sol solution with a solid phase mass percentage of 20% for 10 minutes, take it out and dry it at 100-120°C;

[0049] S2: Soak the sample dried in the above steps in a phosphoric acid solution with a concentration of 30% by mass for 10 minutes, take it out and dry it at 110°C;

[0050] S3: The dried samples in the above steps were kept at a temperature of 1680° C. for 1 hour, and then cooled naturally to obtain the processed 3D printed silica ceramics.

[0051] The 3D printed silica products without post-treatment will completely collapse at high temperature, and the compressive strength of the 3D printed silica ceramic products treated by the method of this embodiment is 1.75 MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com