A single sound source multi-directional power ultrasonic metal solidification device and method

A metal solidification, single sound source technology, applied in the field of advanced material preparation and processing, can solve the problems of random change of multi-channel vibration phase difference, unstable wave superposition effect in melt, unable to guarantee the vibration transmission effect of vibration source, etc. Good ultrasonic treatment effect, solving the random change of multi-channel vibration phase difference, and prolonging the working life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

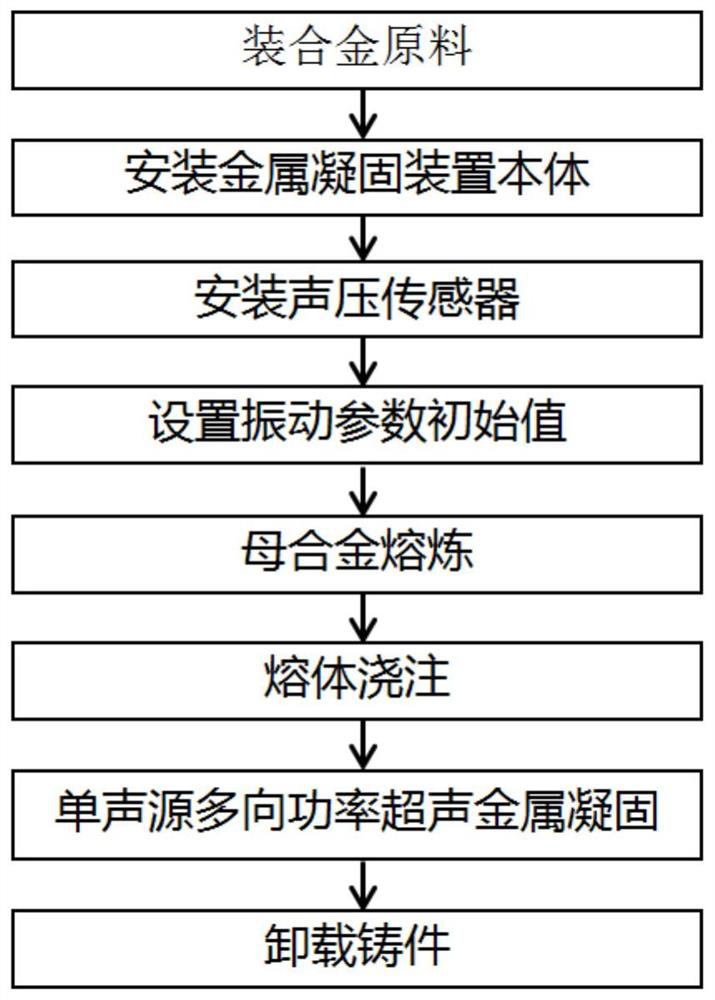

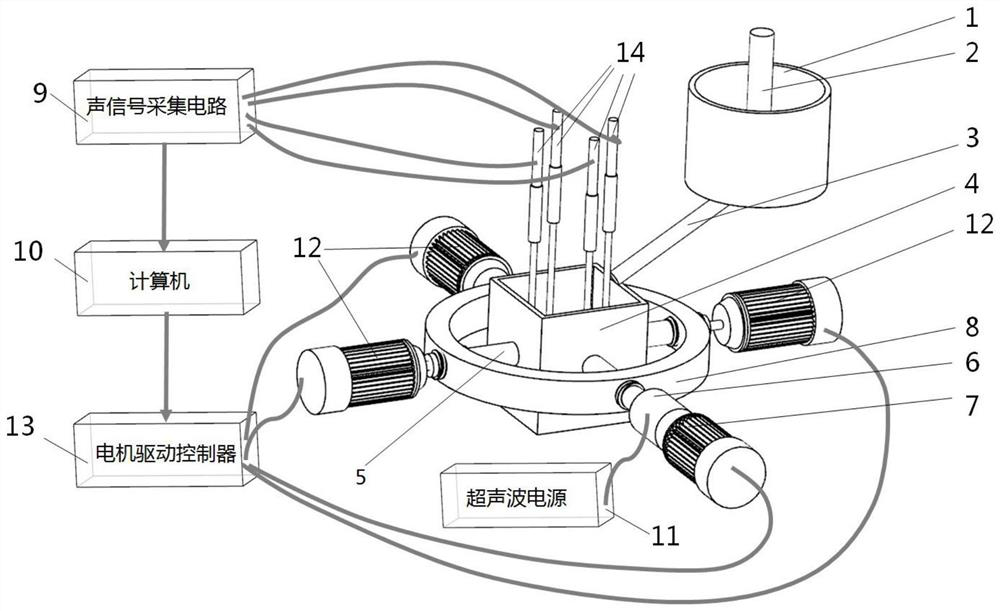

[0053] Such as figure 1 with figure 2 As shown, the single sound source multi-directional power ultrasonic metal coagulation device of the present embodiment comprises a metal coagulation device body, and the metal coagulation device body includes a casting mold 4 poured from the top, a waveguide ring 8 sleeved on the periphery of the casting mold 4 and connecting On the waveguide ring 8 and press the multiple horns 5 on the outer wall of the mold 4 from multiple directions, one of the horns 5 is an active horn and is connected with an ultrasonic transducer 6, and the rest are not connected The horn 5 of the ultrasonic transducer 6 is a passive horn, and the distance between the connection points of two adjacent horns 5 on the waveguide ring 8 is an integer multiple of the half-wavelength of the vibration of the ultrasonic transducer 6 A master alloy pool 1 for heating molten alloy solid raw materials and pouring into the casting mold 4 is arranged above the casting mold 4 ....

Embodiment 2

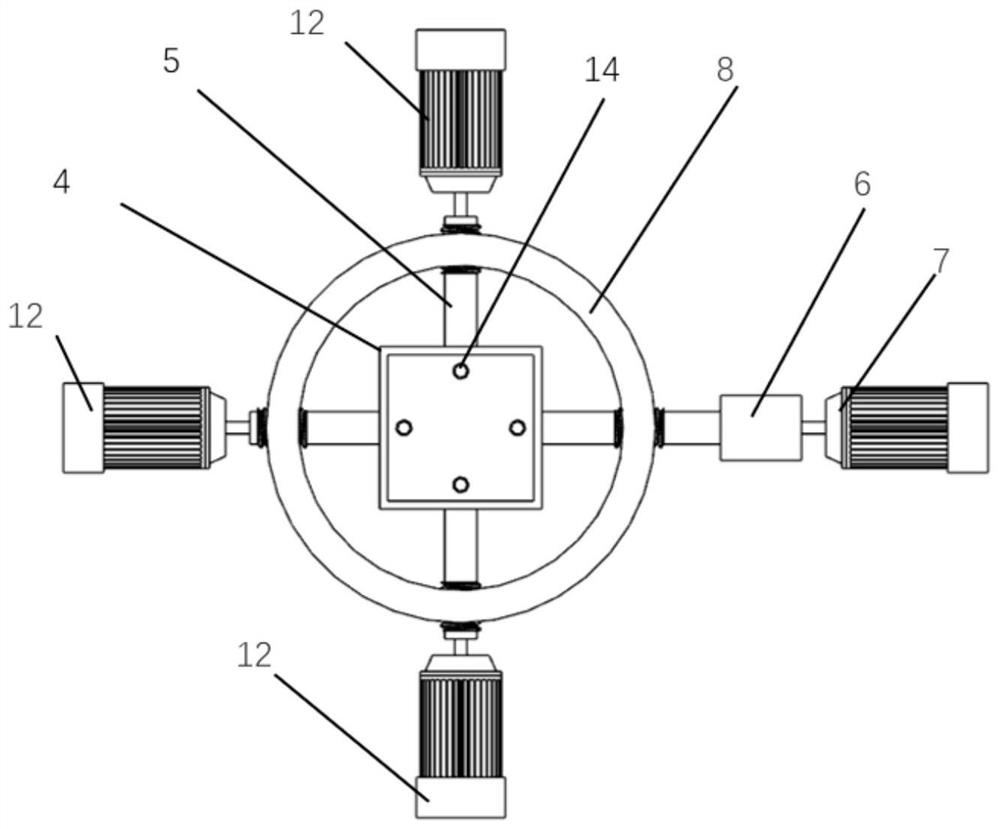

[0078] The difference between this embodiment and Embodiment 1 is that the waveguide ring 8 is a circular waveguide ring, the casting mold 4 is a straight quadrangular prism, and the number of the horns 5 is four and evenly arranged in the waveguide. On the wave ring 8 , four horns 5 are respectively pressed against the four outer walls of the mold 4 . In step 602, the computer 10 drives the ultrasonic transducer motor 7 and each horn motor 12 to rotate through the motor driver 13, so that the ultrasonic transducer motor 7 and the horn motor 12 reach the optimal position, so that multiple horn motors The appropriate specific process for the compression force of the rod 5 to compress the outer wall of the mold 4 is:

[0079] Step 6021, the computer 10 drives the ultrasonic transducer motor 7 and the horn motor 12 opposite to the ultrasonic transducer motor 7 to rotate through the motor driver 13, and adjusts the ultrasonic transducer motor 7 and the horn motor 12 Two respectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com