High-sensitivity vacuum leakage detection device

A high-sensitivity, vacuum technology, applied in measuring devices, using liquid/vacuum degree for liquid tightness measurement, and detecting the appearance of fluid at the leakage point, etc., can solve the problem of insufficient lighting, affect the on-site use of non-destructive inspection personnel, and affect the detection Quality and other issues, to achieve high reliability and operability, easy maintenance and portability, and good scalability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

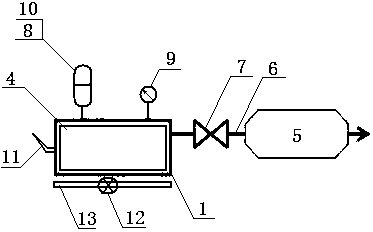

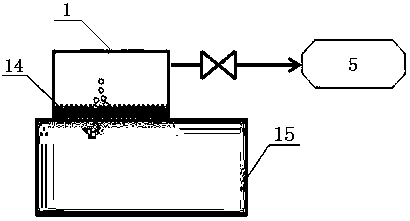

[0029] refer to figure 1 and figure 2 As shown, a high-sensitivity vacuum leak detection device includes a vacuum cover assembly, a vacuum pumping system and an accurate pressure control assembly, wherein:

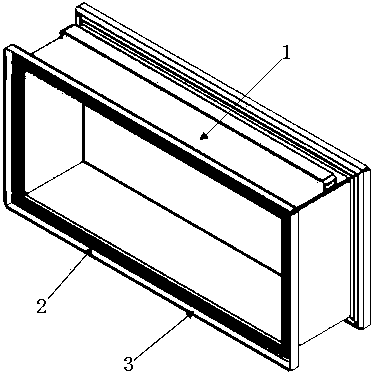

[0030] The vacuum cover assembly includes a vacuum cover 1 and a sealing strip 2, a sealing groove 3 is affixed circumferentially along the edge of the opening end of the vacuum cover 1, and the sealing strip 2 is arranged in the sealing groove 3 for leak detection. It will not fall off during the process, so as to meet the sealing requirements of the leak detection device equipment, and the outer side of the sealing strip 2 is provided with an observation window glass 4;

[0031] The vacuum pumping system includes a vacuum pump 5, and the vacuum pump 5 communicates with the vacuum cover 1 through the corresponding air pipe 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com