Leak checking device prior to lithium battery liquid injection

A lithium battery liquid injection and leak detection technology, which is applied in the field of lithium ion batteries, can solve the problems of long detection time, low detection sensitivity, and the influence of subsequent processes, etc., and achieve the effects of short detection time, high detection sensitivity and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

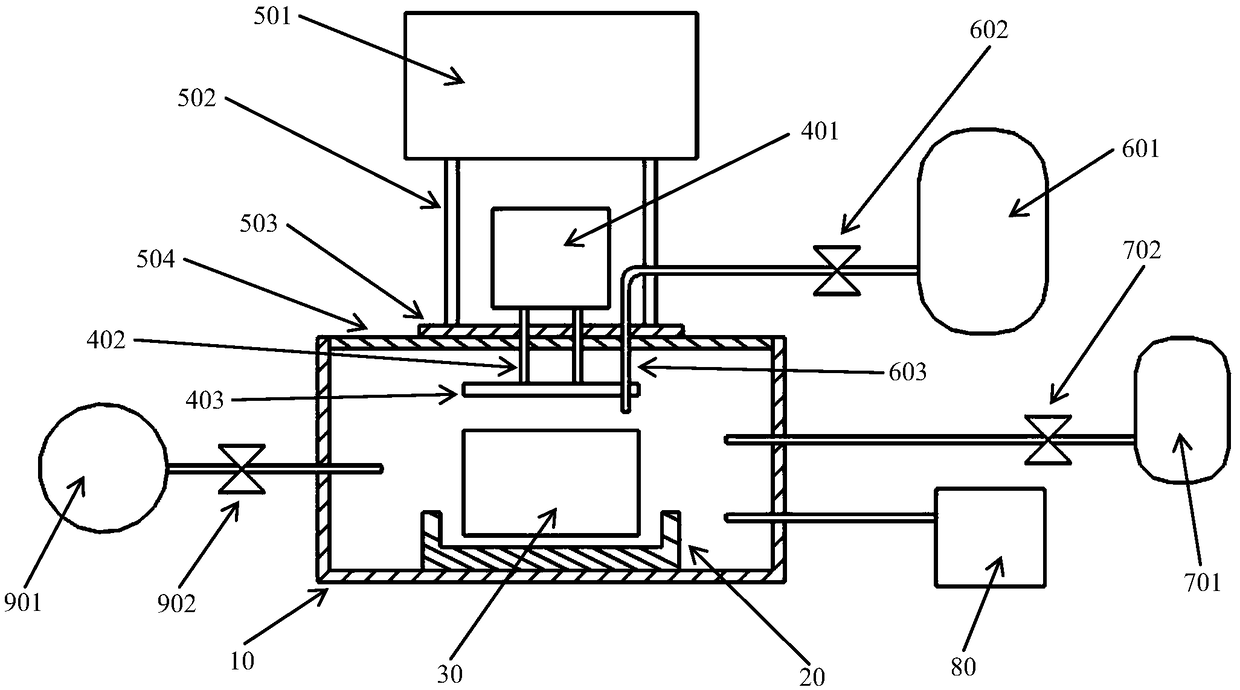

[0019] refer to figure 1 , a leak detection device before liquid injection of a lithium battery proposed in this disclosure, including: a cavity 10, a battery positioning assembly 20, a leak detection cylinder assembly, a sealed cylinder assembly, a helium source 601, a helium hose 603, a compressed air Source 701, helium detector 80 and vacuum pump 901.

[0020] The sealing cylinder assembly includes: a sealing cylinder 501 , a sealing guide rod 502 , a sealing push plate 503 and a sealing cover 504 . The sealing push plate 503 is installed on the sealing cylinder 501 through the sealing guide rod 502, and the sealing cylinder 501 is used to drive the sealing push plate 503 to move up and down. The seal cover 504 is installed on the side of the seal push plate 503 away from the seal cylinder 501 and moves up and down following the seal push plate 503 . When the sealing cover 504 is moved down, it cooperates with the cavity 10 to form a sealed cavity, which provides a sealed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com