ELectroacid-chromism responsive fiLm

A color-changing film and electroacid technology, applied in nonlinear optics, instruments, optics, etc., can solve the problems of low stability, slow response speed and non-repeatable use, etc., and achieve stable display and fast color response speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

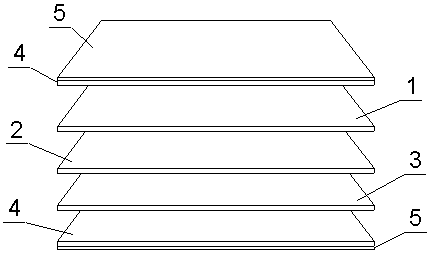

[0028] Electroacid color-changing film 1 is formed by curing 20 parts of PMMA, 10 parts of electrolyte solution, 5 parts of electroacid, 3 parts of acid-responsive material, 4 parts of plasticizer, 1 part of leveling agent, and 1 part of clearing agent;

[0029] The conductive film 2 is formed by curing 20 parts of PMMA, 8 parts of electrolyte solution and 2 parts of plasticizer;

[0030] The ion storage film 3 is formed by curing 20 parts of PMMA, 8 parts of electrolyte solution, 4 parts of electroacid, 2 parts of plasticizer, and 1 part of leveling agent.

Embodiment 2

[0032] Electroacid color-changing film 1 is formed by curing 23 parts of PMMA, 11 parts of electrolyte solution, 5 parts of electroacid, 3 parts of acid-responsive material, 4 parts of plasticizer, 1 part of leveling agent, and 1 part of clearing agent;

[0033] The conductive film 2 is formed by curing 22 parts of PMMA, 9 parts of electrolyte solution and 3 parts of plasticizer;

[0034] The ion storage film 3 is formed by curing 22 parts of PMMA, 9 parts of electrolyte solution, 4 parts of electroacid, 3 parts of plasticizer, and 1 part of leveling agent.

Embodiment 3

[0036] Electroacid color-changing film 1 is formed by curing 26 parts of PMMA, 12 parts of electrolyte solution, 6 parts of electroacid, 4 parts of acid-responsive material, 6 parts of plasticizer, 2 parts of leveling agent, and 2 parts of clearing agent;

[0037] The conductive film 2 is formed by curing 24 parts of PMMA, 10 parts of electrolyte solution and 4 parts of plasticizer;

[0038] The ion storage film 3 is formed by curing 24 parts of PMMA, 10 parts of electrolyte solution, 5 parts of electroacid, 2 parts of plasticizer, and 2 parts of leveling agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Coloring efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com