A dynamic optical coating with changing refractive index, its preparation method and application method

An optical coating and refractive index technology, which is applied in coatings, polyester coatings, polyamide coatings, etc., can solve the problems that limit the application of optical coatings, and achieve the effects of fast color response, simple process, and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

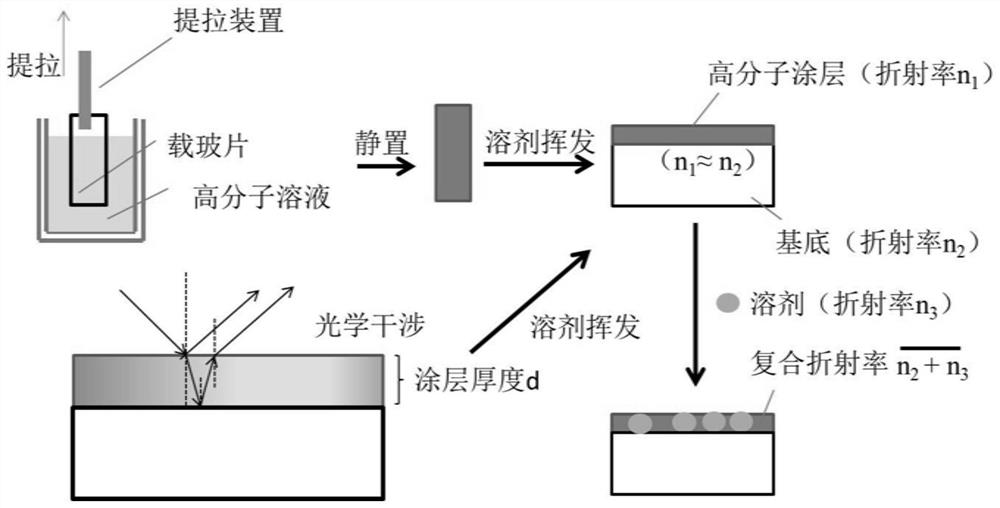

Method used

Image

Examples

Embodiment 1

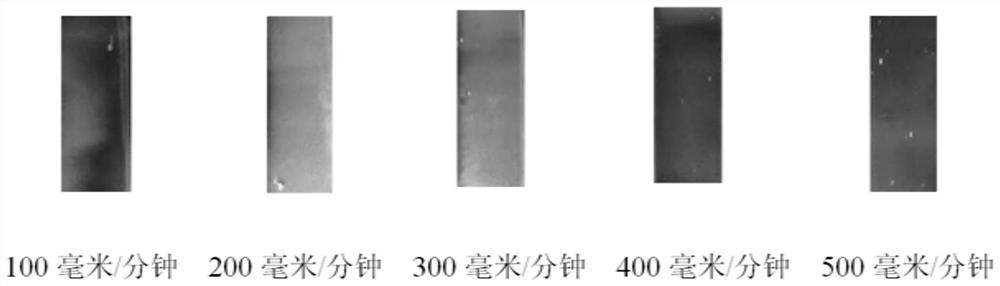

[0036]Dissolve 3 parts by mass of polymer resin polyethylene, 3 parts by mass of polypropylene, 4 parts by mass of polystyrene, and 15 parts by mass of polylactic acid in 200 parts by mass of N,N-dimethylformamide and 200 parts by mass of dimethyl sulfoxide parts, 400 parts by mass of dichloromethane, 100 parts by mass of ethyl acetate, 50 parts by mass of dioxane and 50 parts by mass of water, to form a polymer solution with a mass volume concentration of 25g / L, using a pulling device , insert the ordinary glass sheet vertically into the solution at a certain speed (the speeds are 100mm / min, 200mm / min, 300mm / min, 400mm / min and 500mm / min), and immediately insert the ordinary glass piece vertically at the same speed. The glass sheet is pulled above the liquid level, so that the surface of the ordinary glass sheet is covered with a polymer coating, and placed in an environment with a humidity of 50% and a temperature of 90 degrees until the solution is completely evaporated and t...

Embodiment 2

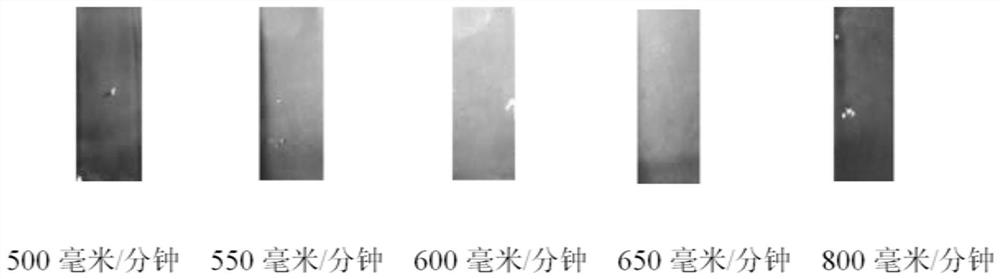

[0038] 30 parts by mass of polymer resin polylactic acid, 10 parts by mass of polyvinyl chloride, 5 parts by mass of acrylonitrile-butadiene-styrene copolymer, and 5 parts by mass of polyurethane are dissolved in 650 parts by mass of chloroform, 300 parts by mass of tetrahydrofuran, In the mixed solvent of 10 mass parts of acetone, 20 mass parts of isopropanol, 20 mass parts of hexanaphthene, be made into mass volume concentration and be 50g / L macromolecular solution, adopt lifting device, polyethylene substrate is with certain speed ( The speeds are 500 mm / min, 550 mm / min, 600 mm / min, 650 mm / min and 800 mm / min) into the solution vertically, and immediately pull the polyethylene substrate vertically above the liquid level at the same speed, so that The surface of the polyethylene substrate is covered with a polymer coating, and placed in an environment with a humidity of 30% and a temperature of 150 degrees until the solution is completely evaporated and the coating is colorles...

Embodiment 3

[0040] 1 mass part of polymer resin polysulfone, 0.5 mass part of polyamide, 0.5 mass part of polybutylene adipate terephthalate, 7.5 mass parts of polymethyl methacrylate, styrene-butadiene-styrene 0.5 parts by mass of the block copolymer is dissolved in a mixed solvent of 500 parts by mass of dichloromethane, 200 parts by mass of chloroform, 250 parts by mass of ethanol and 50 parts by mass of water to form a polymer solution with a mass volume concentration of 10 g / L. Using a lifting device, insert the polyimide substrate vertically into the solution at a certain speed (the speeds are 200 mm / min, 220 mm / min, 240 mm / min, 260 mm / min and 280 mm / min), and then immediately Pull the polyimide substrate vertically above the liquid level at the same speed, so that the surface of the polyimide substrate is covered with a polymer coating, and placed in an environment with a humidity of 80% and a temperature of 45 degrees until the solution evaporates completely and the coating Colorl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com