Method for rapidly calculating gas concentration of distillation column

A gas concentration and fast calculation technology, applied in calculation, special data processing applications, instruments, etc., can solve the problems of difficult detection, small range of pressure and temperature changes, and inconvenient calculation by table lookup, so as to achieve difficult detection and improve Computational Efficiency Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solution of the present invention will be further specifically described below through specific examples.

[0023] A fast calculation method for gas concentration in a rectification tower:

[0024] (1) Obtain the pressure and temperature of the rectification section and the stripping section;

[0025] (2) Obtain the gas concentration under the corresponding pressure and temperature by means of table lookup or measurement;

[0026] (3) Construct a multiple regression model about gas concentration under pressure and temperature;

[0027] Multiple regression model for gas concentration under pressure and temperature: Y=Xβ,

[0028] in,

[0029] x i Indicates pressure, z i means x i temperature under pressure, y i is the corresponding pressure x i and temperature z i Under the gas concentration, β is the regression parameter.

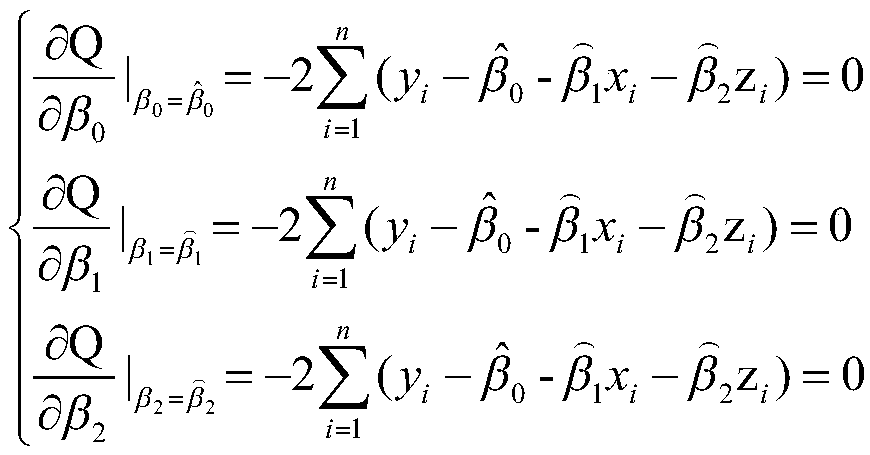

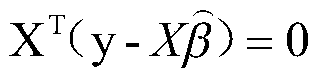

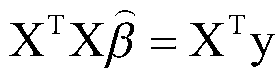

[0030] (4) Use the least squares method to estimate the estimated value of the regression parameters, including:

[0031]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com