Decelerator assembly and disassembly teaching workbench

A technology of a reducer and a workbench, applied in the field of teaching tools, can solve the problems of incomprehension of students, poor teaching effect of students, poor practical teaching effect, etc., and achieve the effect of reasonable structure design, good teaching effect and preventing rotation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

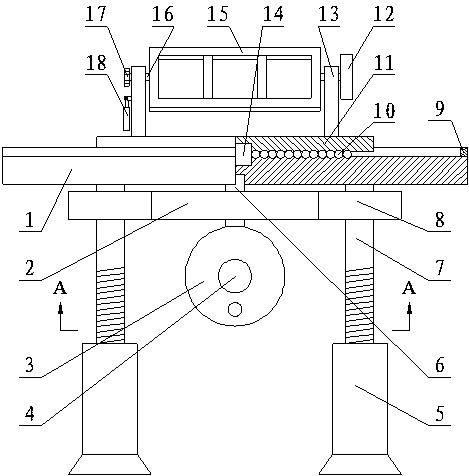

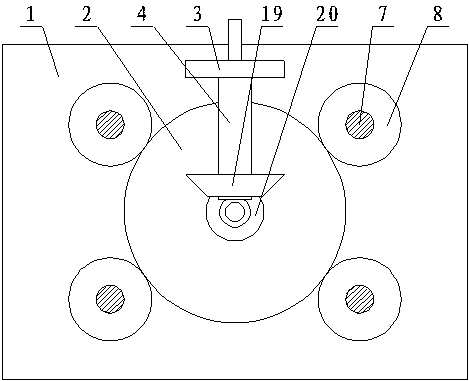

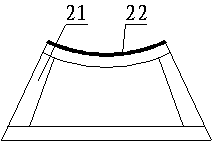

[0019] Such as Figure 1-4 As shown, a reducer disassembly and assembly teaching workbench, which includes an operating table 1, the center of the lower surface of the operating table 1 is provided with a rotating shaft A6, and the rotating shaft A6 is provided with a gear A2. A2 is meshed with a gear B8, the gear B8 is fixed on the rotating shaft B7, the rotating shaft B7 is arranged on the lower surface of the console 1, and the lower end of the rotating shaft B7 is threadedly connected with a supporting leg 5. A bevel gear A20 is also provided on the rotating shaft A6, and the bevel gear B19 is meshed with the bevel gear A20, and the bevel gear B19 is fixed on the rotating shaft C4, and the rotating shaft C4 is arranged on the console 1 On the lower surface, the outer end of the rotating shaft C4 is connected to the rocking wheel A3, and the upper surface of the operating table 1 is connected to the rotating table 11 through the rotating shaft D14, and the upper surface of ...

Embodiment 2

[0022] Such as Figure 1-4 As shown, a reducer disassembly and assembly teaching workbench, which includes an operating table 1, the center of the lower surface of the operating table 1 is provided with a rotating shaft A6, and the rotating shaft A6 is provided with a gear A2. A2 is meshed with a gear B8, the gear B8 is fixed on the rotating shaft B7, the rotating shaft B7 is arranged on the lower surface of the console 1, and the lower end of the rotating shaft B7 is threadedly connected with a supporting leg 5. A bevel gear A20 is also provided on the rotating shaft A6, and the bevel gear B19 is meshed with the bevel gear A20, and the bevel gear B19 is fixed on the rotating shaft C4, and the rotating shaft C4 is arranged on the console 1 On the lower surface, the outer end of the rotating shaft C4 is connected to the rocking wheel A3, and the upper surface of the operating table 1 is connected to the rotating table 11 through the rotating shaft D14, and the upper surface of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com