Intelligent alternating current servo drive with high integration density and high power density

A high-power density, high-integration technology, applied in the direction of connection with control/drive circuits, electric components, electrical components, etc., can solve problems such as insufficient reliability, inability to balance integration and power density, and improve anti-interference ability. , Optimized heat dissipation design, the effect of high power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

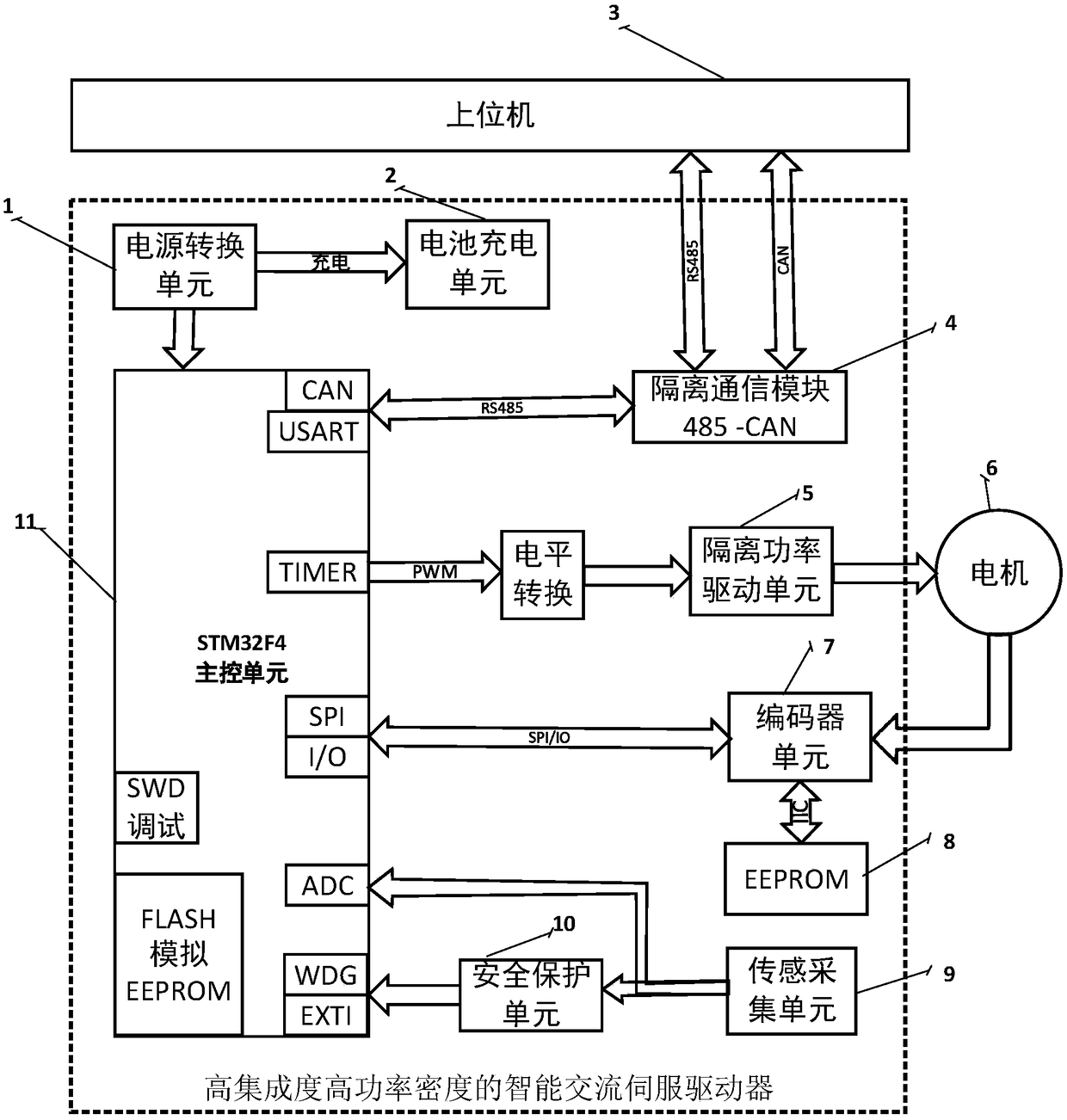

[0044] The invention proposes an intelligent AC servo motor driver that integrates a multi-turn absolute encoder on the driver, significantly reduces the number and volume of circuit boards inside the robot joint, and improves power density and integration.

[0045] The intelligent AC servo driver includes integrated on a circuit board: power conversion unit 1, battery charging unit 2, STM32F4 main control unit 11, isolated communication module 4, isolated power drive unit 5, encoder unit 7, EEPROM chip 8. The safety protection unit 10 and the sensing collection unit 9 .

[0046] STM32F4 main control unit 11 mainly completes external communication, encoder configuration and communication, analog quantity acquisition, safety information interruption, and uses internal FLASH analog EEPROM function to realize power-down storage of data such as motor parame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com