Drive circuit and vehicle lamp

A technology for driving circuits and lamps, applied in the direction of headlights, electric light sources, electrical components, etc., can solve the problems of high cost and large number of circuit components, and achieve the effect of suppressing flicker

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

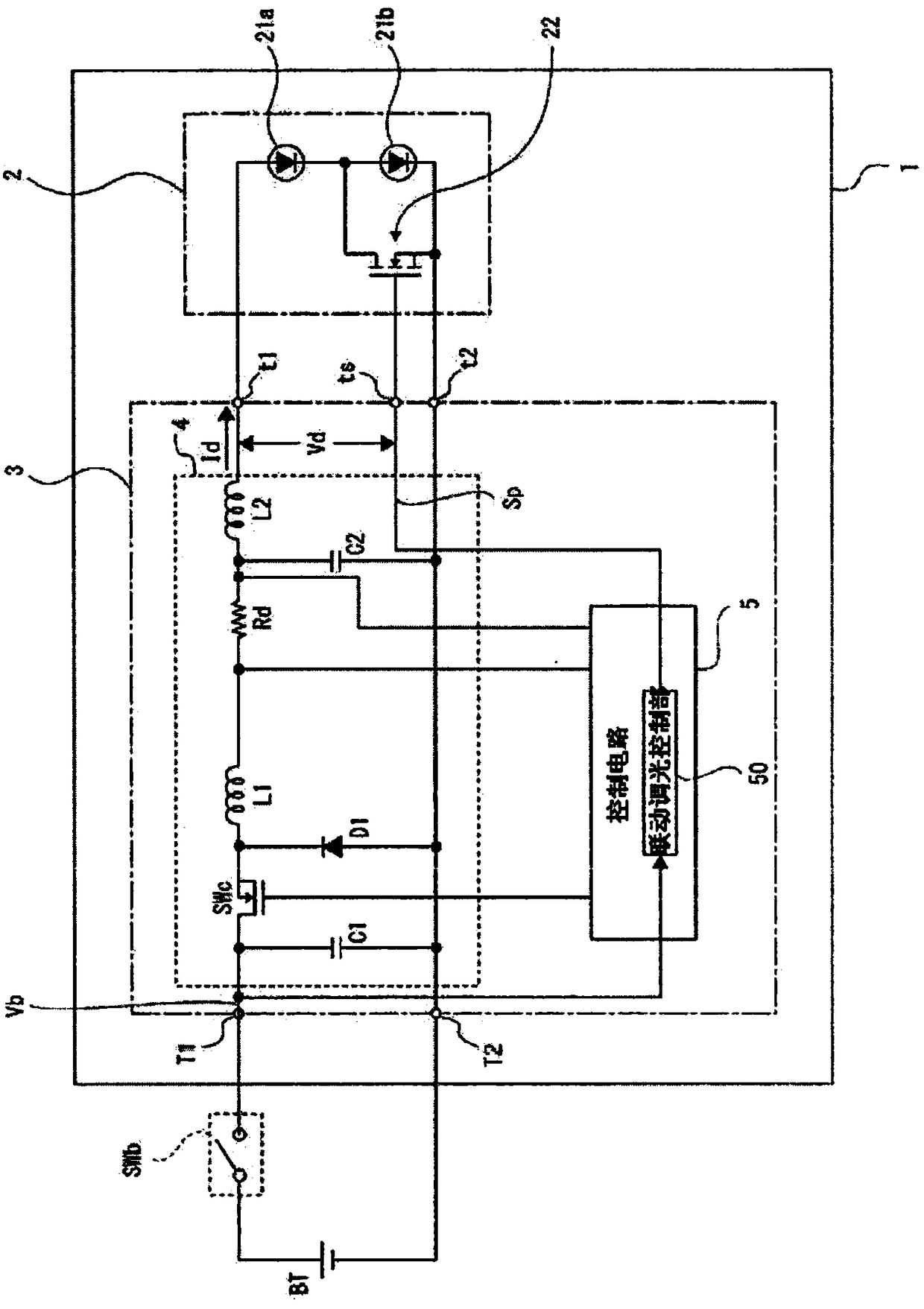

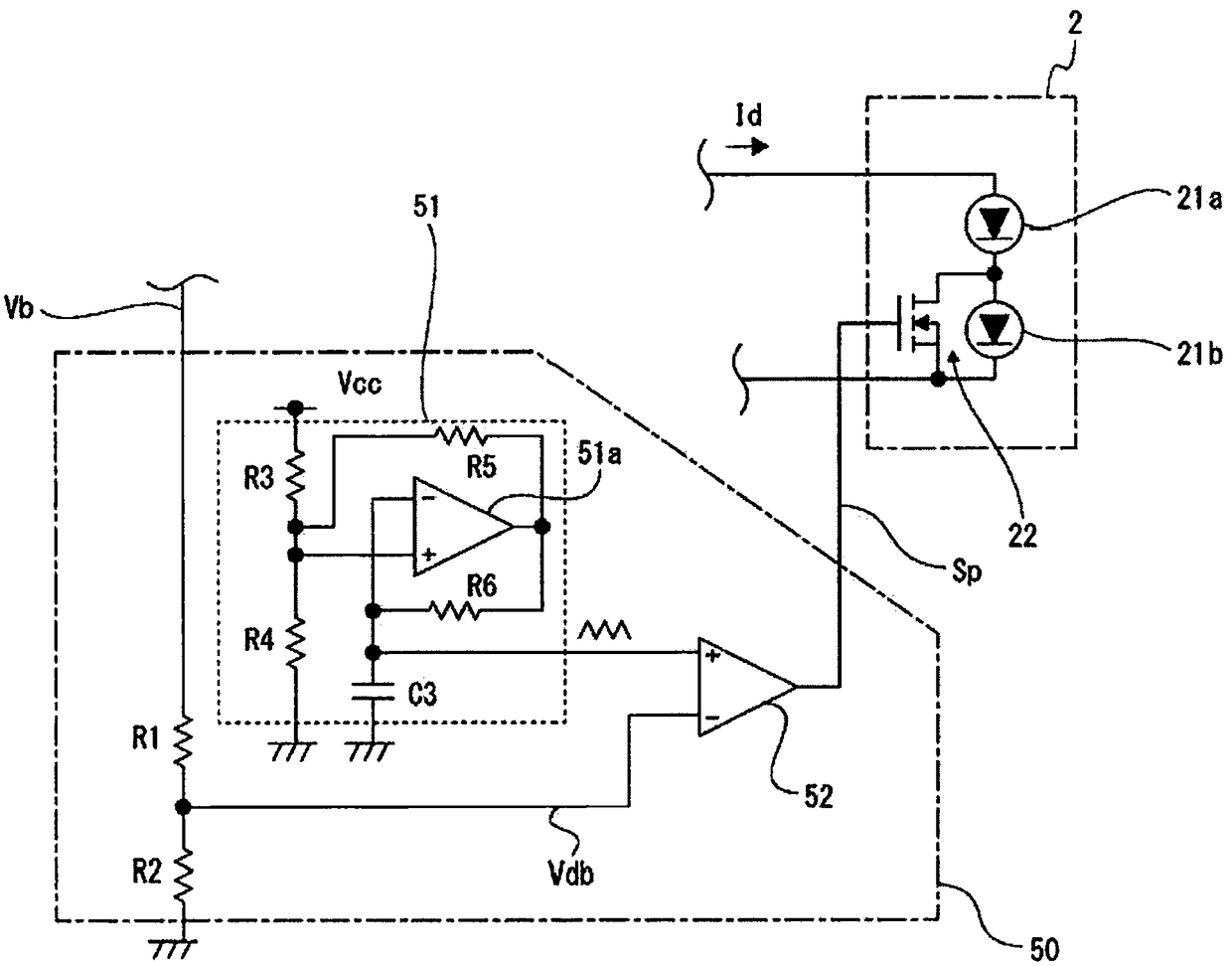

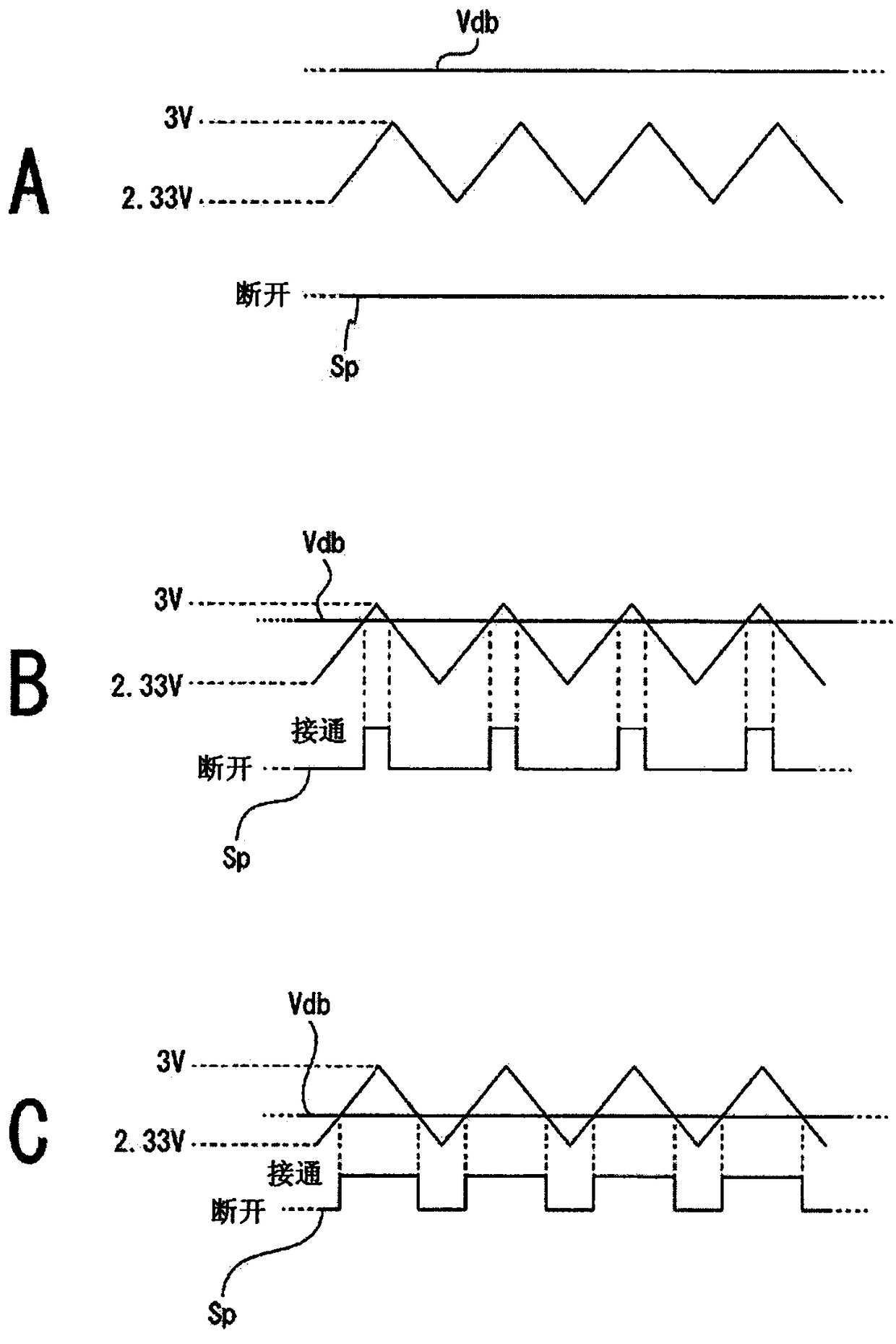

[0039] Next, a drive circuit and a vehicle lamp according to embodiments of the present invention will be described with reference to the drawings.

[0040] figure 1 It is a circuit block diagram for explaining the schematic internal structure of the vehicle lamp 1 which is 1st Embodiment. In addition, in figure 1 In FIG. 1 , an on-vehicle battery BT provided in the vehicle outside the vehicular lamp 1 and an input switch SWb for turning on and off the input voltage from the on-vehicle battery BT to the vehicular lamp 1 are shown together.

[0041] In this example, the premise is that the output voltage (battery voltage) of the battery BT is about 12V.

[0042] The vehicle lamp 1 is a headlight (vehicle headlamp) in which a pair of two lamps are arranged on the left and right sides of the front end of the vehicle.

[0043] As shown in the figure, the vehicle lamp 1 includes: a light emitting unit 2 having a plurality of semiconductor light emitting elements 21; and a drive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com