Acrylic polymer composition

A technology of acrylic polymer and composition, applied in the field of acrylic polymer composition, can solve problems such as no report deterioration inhibition, and achieve the effect of preventing heating deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0169]

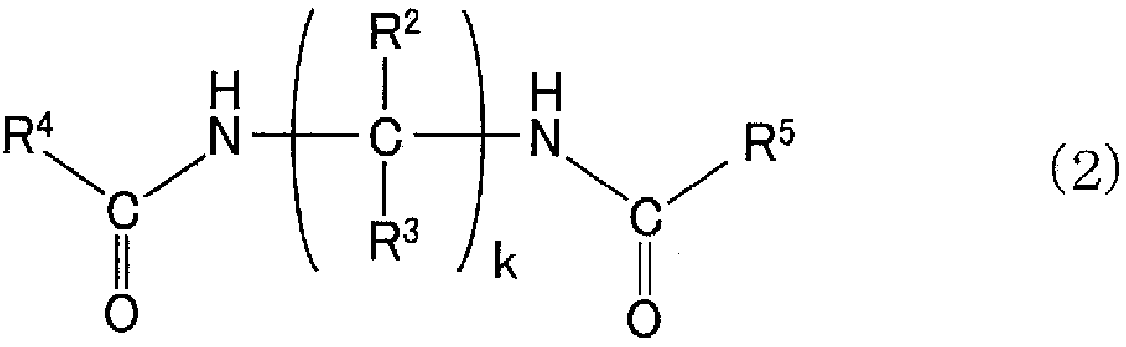

[0170] The method for producing the acrylic polymer composition of the present invention is not particularly limited, and examples include a method of mixing an acrylic polymer, a polyfunctional organic compound having an amide group, and various compounding agents added as necessary.

[0171] The mixing method is not particularly limited, and examples thereof include a method of kneading using a kneader such as a roll kneader, Intermix, kneader, Banbury kneader, or screw kneader. In addition, mixing can be performed in a solvent.

[0172] In addition, in the case of compounding a crosslinking agent, it is prepared by using a mixer such as a Banbury mixer, a Brabender mixer, an Intermex, a kneader, etc., to remove the crosslinking agent and The components other than the heat-unstable cross-linking aid and the like are kneaded, then transferred to a roll kneader, etc., and the cross-linking agent and the heat-unstable cross-linking agent are added, and secondary knea...

Embodiment

[0180] Hereinafter, the present invention will be specifically described with reference to Examples and Comparative Examples. In addition, unless otherwise specified, "parts" in each example are based on weight.

[0181] Various physical properties were evaluated according to the following methods.

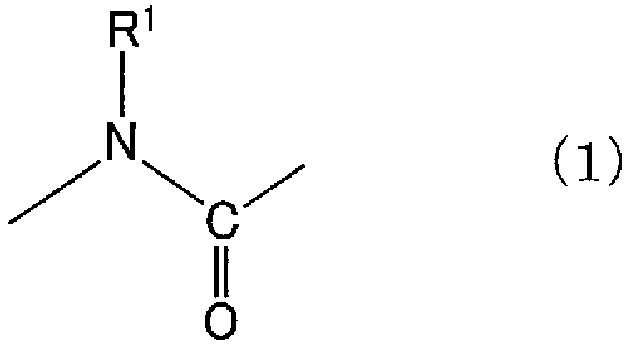

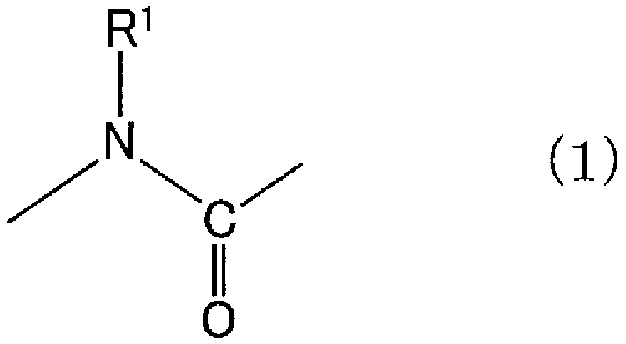

[0182] [Measurement of half-life of polyfunctional organic compound having amide group]

[0183] Regarding the half-life of the polyfunctional organic compound having an amide group, using a differential thermal gravimetric simultaneous measurement device ("TG / DTA7200", manufactured by SII Corporation), the temperature was raised according to the following heating program, and the heating temperature of the measurement device was 180°C. °C, the weight loss at the time when the sample temperature was stabilized at 190 °C was measured, and the time until the weight became half was obtained, which was regarded as the half-life of the polyfunctional organic compound having an amide g...

Synthetic example 1

[0195] [Synthesis Example 1: Synthesis of Acrylic Polymer]

[0196] In the polymerization reactor with thermometer, stirring device, nitrogen introduction pipe and decompression device, add 200 parts of water, 3 parts of sodium lauryl sulfate, 100 parts of ethyl acrylate, and repeatedly perform degassing and decompression utilizing decompression. After nitrogen replacement and full removal of oxygen, add 0.002 parts of sodium formaldehyde sulfoxylate and 0.005 parts of cumene hydroperoxide to initiate emulsification polymerization reaction at normal pressure and temperature, continue to react until the polymerization conversion rate reaches 95%, and add polymerization to terminate agent to terminate the polymerization. Then, the obtained emulsified polymerization solution was coagulated using an aqueous magnesium sulfate solution, washed with water, and dried to obtain a rubbery acrylic polymer (polyethyl acrylate).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com