Total space white light LED (light emitting diode) device

A LED device, full-space technology, applied in the direction of electric solid-state devices, semiconductor devices, electrical components, etc., can solve the problems of chip heating up, weakening light output, etc., and achieve the effects of preventing heating degradation, reducing light loss, and improving luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with accompanying drawing.

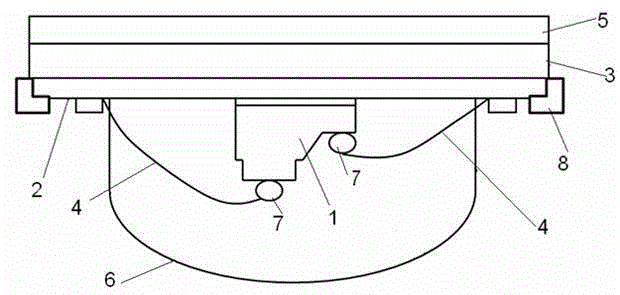

[0012] refer to figure 1 , the full-space white LED device of the present invention comprises a quartz substrate 3, one side of the quartz substrate 3 is coated with a phosphor powder glue 5, the thickness of the phosphor powder glue can be adjusted according to different needs, and the other side of the quartz substrate 3 adopts The method of CN1850589 or CN101565822 grows a cubic boron nitride film 2, and a reflective bowl 6 is placed on the cubic boron nitride film 2 to form a closed cavity. In the cavity, n LED chips 1 connected in parallel or in series are fixed on the cubic nitrogen film with transparent heat-conducting adhesive. On the boron film 2, n≥1, the illustration shows an LED chip, and the LED chip can be mounted upside down or upside down. The two electrodes 7 of the LED chip are led out of the cavity by wires 4, and a radiator 8 connected with the cubic bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com