Aluminum alloy sheet and aluminum alloy sheet manufacturing method

A technology of aluminum alloy plate and manufacturing method, applied in the field of 6000 series aluminum alloy plate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

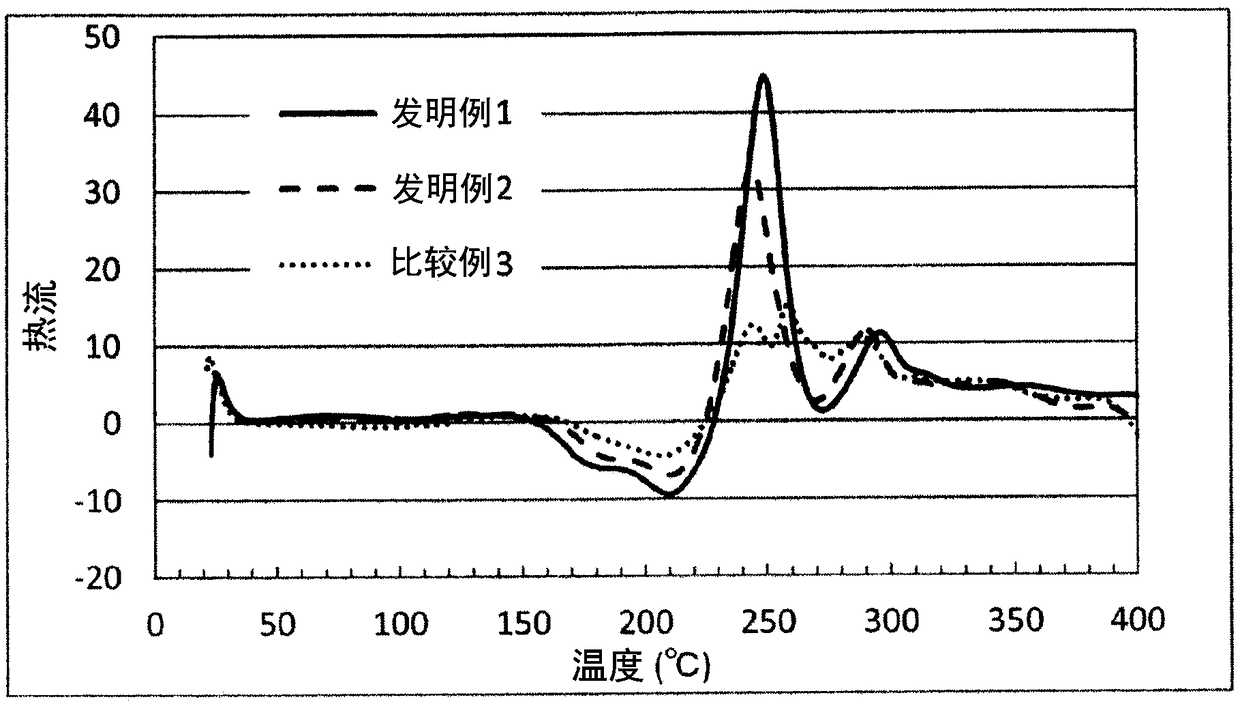

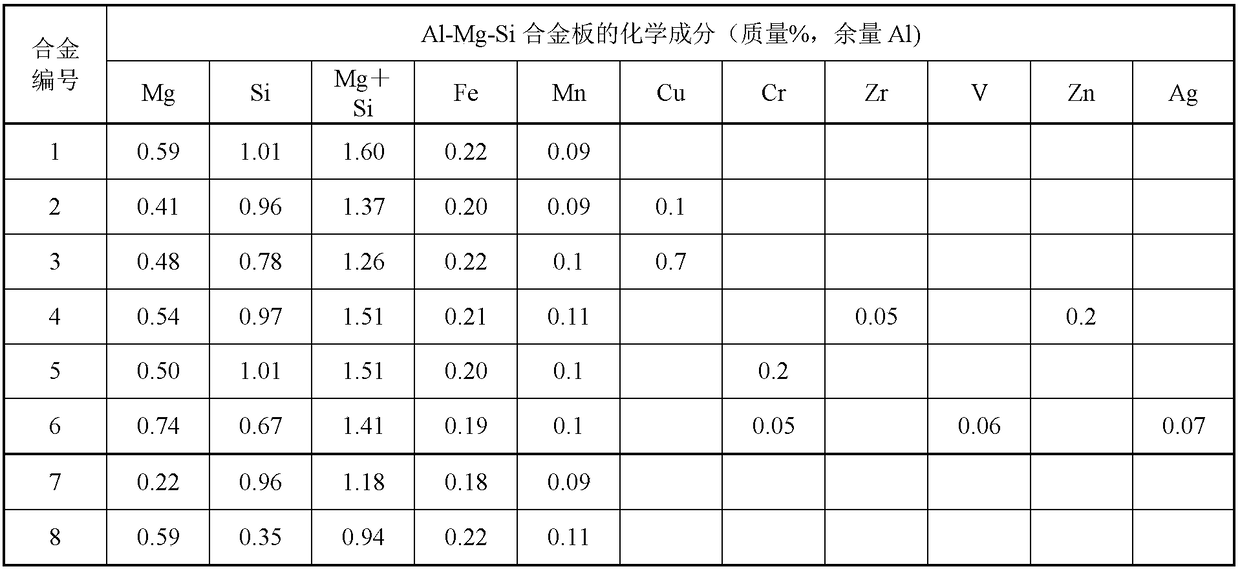

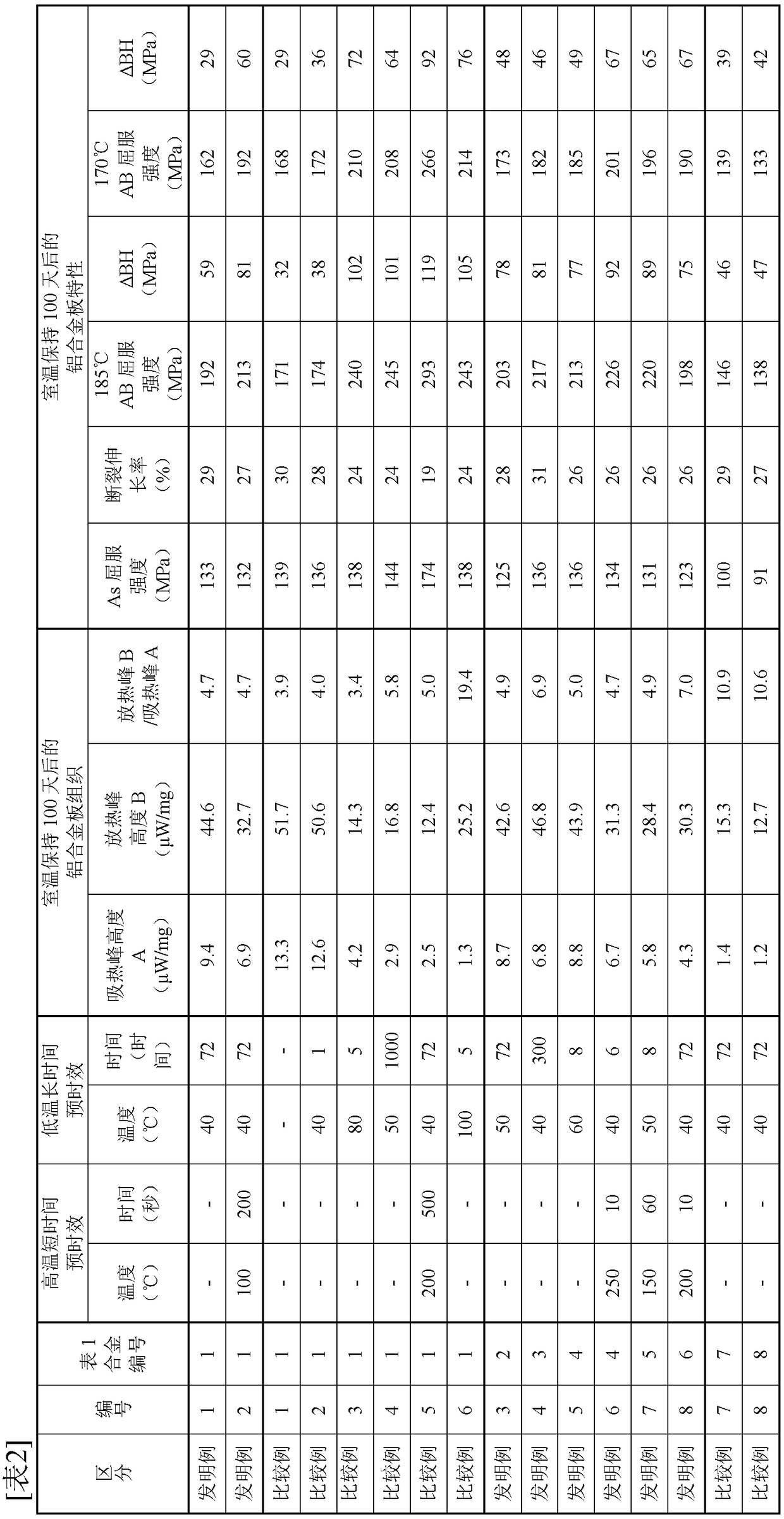

[0099] Next, examples of the present invention will be described. 6000-series aluminum alloy sheets having different structures specified by DSC according to the present invention were produced by changing the composition and production conditions. Then, after the board was kept at room temperature for 100 days after manufacture, the As yield strength (yield strength before bake coating hardening treatment) and AB yield strength (yield strength after bake coating hardening treatment), and the elongation at break were measured and evaluated respectively. Elongation, BH (coating bake hardening). The results are shown in Tables 1 and 2.

[0100] Specifically, the separate production method was performed by variously changing the pre-aging treatment conditions after solution treatment and quenching treatment as shown in Table 2 for 6000 series aluminum alloy plates having the compositions shown in Table 1. Here, in the display of the content of each element in Table 1, the numer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com