Automated production method of integrated support lamp

A production method and technology for bracket lights, which can be applied to other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of low production and assembly efficiency, labor-intensive, unsuitable for integrated bracket lights, etc., so as to improve assembly production efficiency and reduce costs. and the effect of labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

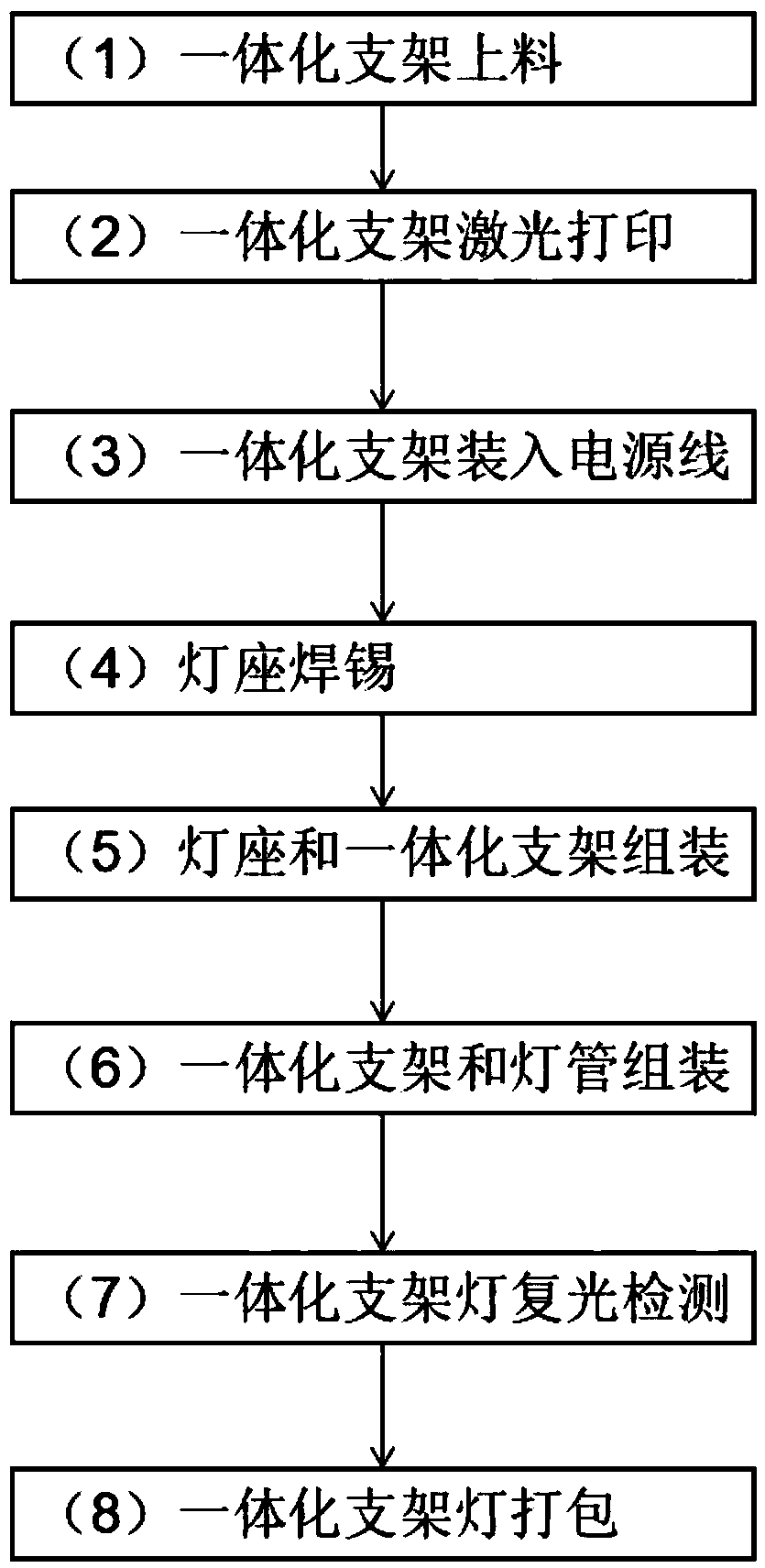

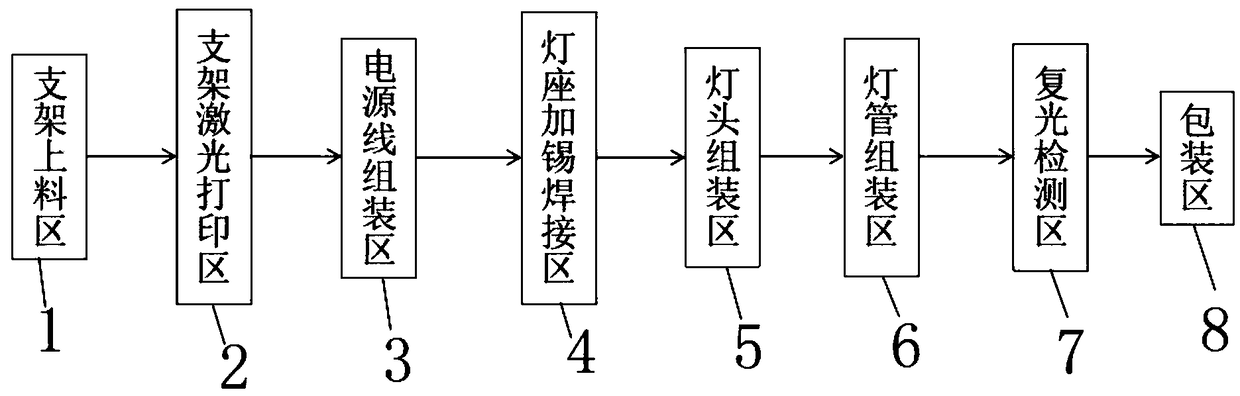

[0038] Such as Figure 1-2 As shown, the present invention provides an automatic production method for an integrated bracket lamp, which includes the following steps: feeding the integrated bracket, laser printing the integrated bracket, loading the integrated bracket into the power cord, soldering the lamp holder, and integrating the lamp holder Bracket assembly, integrated bracket and lamp assembly, integrated bracket light recovery detection and integrated bracket light packaging. The production line involved in the automatic production method of the integrated bracket lamp includes a bracket feeding area 1, a bracket laser printing area 2, a power cord assembly area 3, a lamp holder tinning welding area 4, a lamp cap assembly area 5, and a lamp tube assembly area 6. Fuguang detection area 7 and packaging area 8. The detailed steps of the automatic production method of the integrated bracket lamp are as follows:

[0039] (1) Integrated bracket loading: The integrated bracke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com