A lithium-ion cell parallel network automatic cutting spot welding device

A spot welding device, lithium-ion technology, applied in the direction of circuits, electrical components, battery pack parts, etc., can solve the problems of high labor intensity for workers, low efficiency of nickel strip parallel network production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

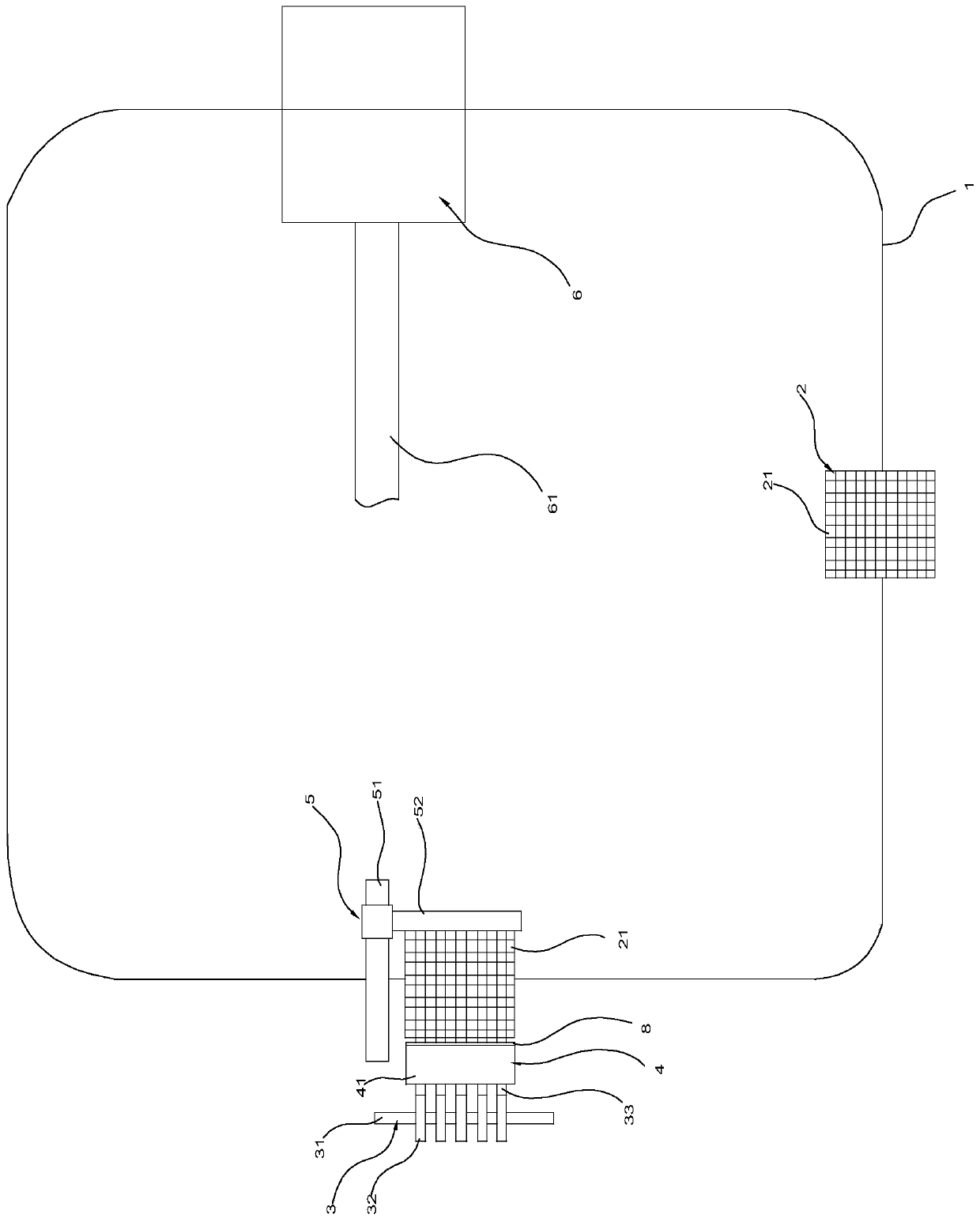

[0024] Such as Figures 1 to 6 As shown, the parallel-connected automatic cut-and-place spot welding device for lithium-ion batteries in this implementation includes a closed track 1, a plurality of rotating transport components 2, a cut-and-place mechanism and a spot welding mechanism 6.

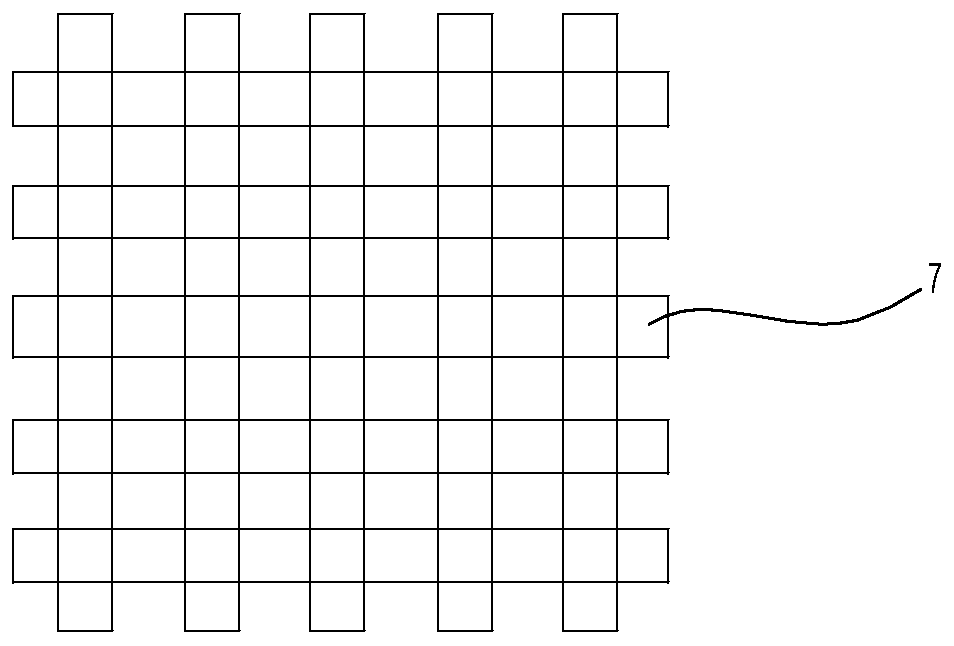

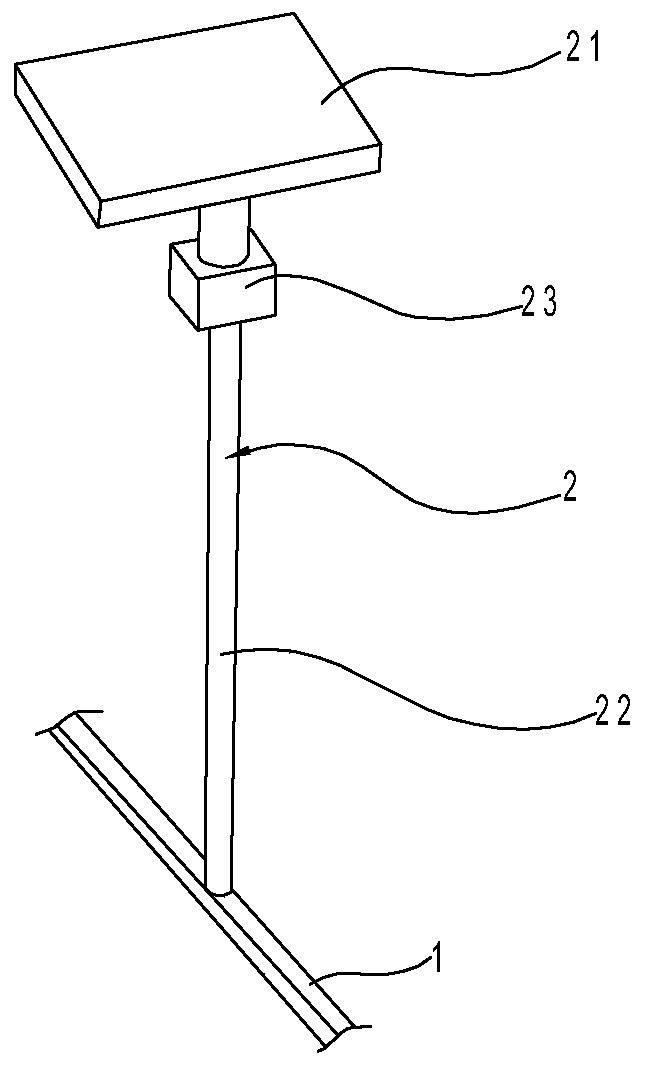

[0025] Wherein, the airtight track 1 is a circular track or a square track, and the rotary transport assembly 2 moves along the airtight track 1, and each rotary transport assembly 2 includes a support rod 22, a rotary cylinder 23, and a nickel belt positioned along the airtight track 1. Disc 21, rotating cylinder 23 is arranged on the top of support rod 22, the output end of rotating cylinder 23 is upward, nickel belt positioning disk 21 is arranged on the output end of rotating cylinder 23, nickel belt positioning disk 21 is provided with a plurality of h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com