Tire burst preventive safety mechanism for automobile

A technology for safety mechanisms and run-flat tires, which is applied to vehicle parts, tire parts, transportation and packaging, etc., can solve problems such as tire control, deviation, hard contact with rims, etc., and achieve the effect of reducing fuel consumption and reducing product weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

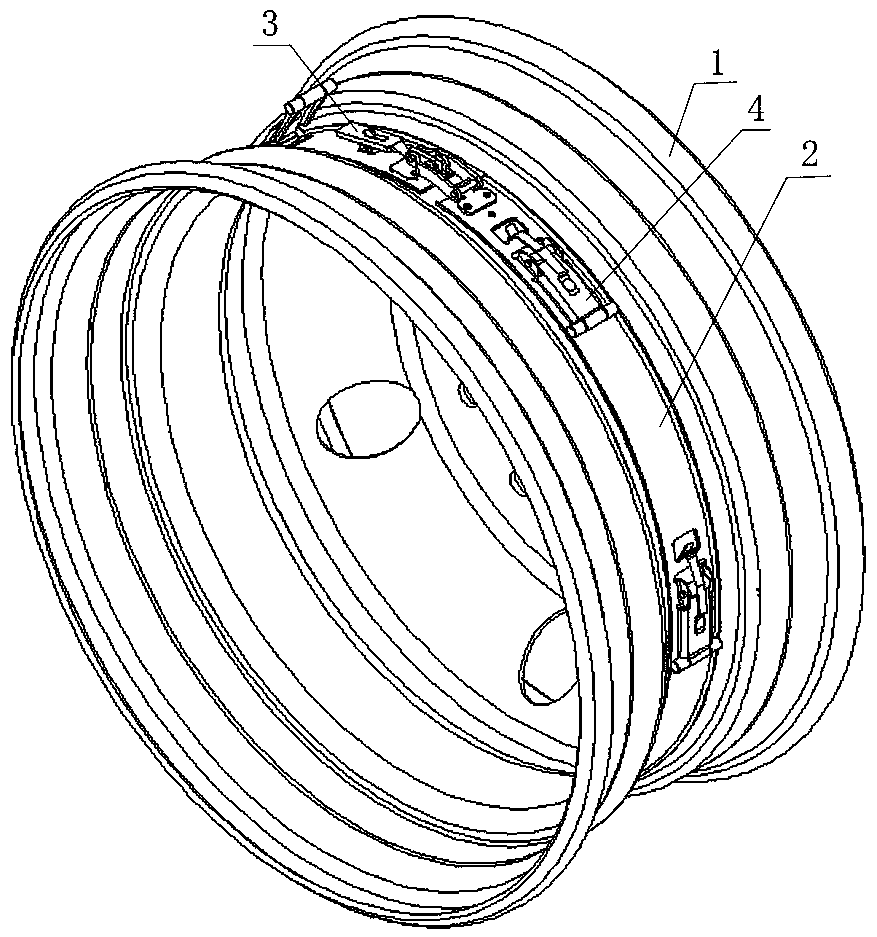

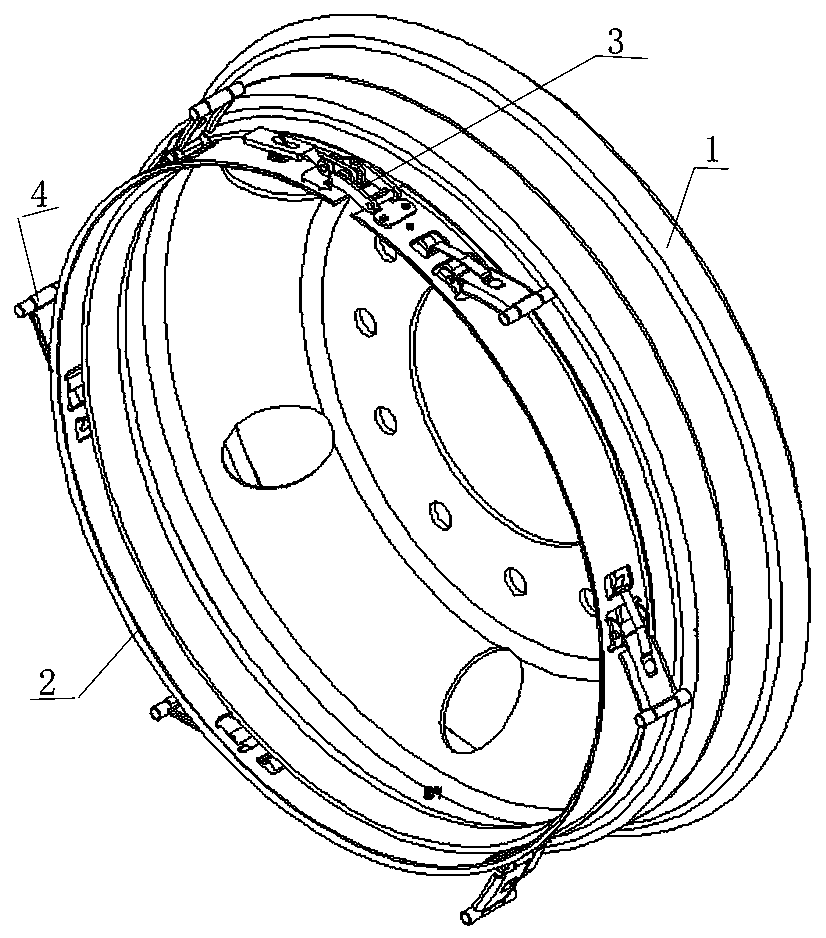

[0039] The present invention as Figure 1-9 shown.

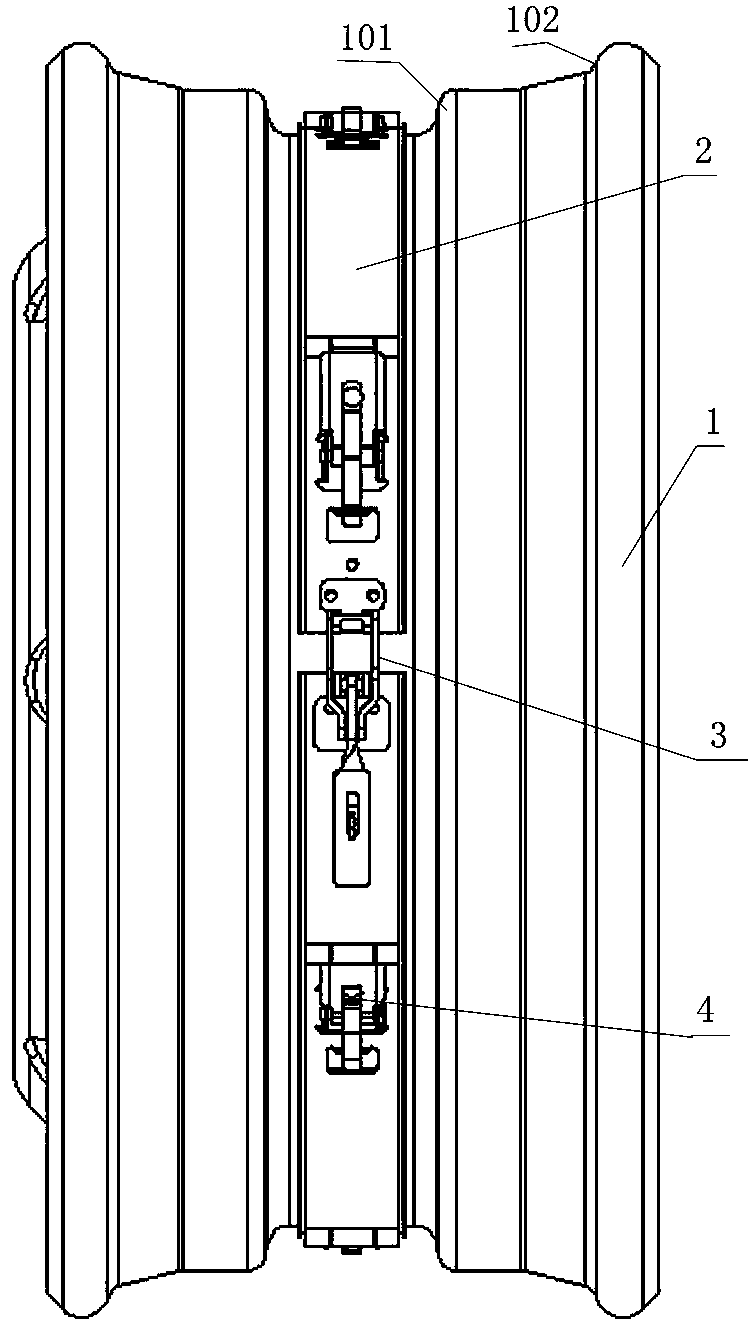

[0040] A safety mechanism for an automobile run-flat tire, comprising a support ring 2 installed on the annular outer surface of a rim 1, the support ring 2 has at least one notch, which is disconnected at the notch, and the support ring 2 is provided with a connecting part at a notch 3. It is used to connect the supporting ring 2. The connecting part 3 includes a connecting seat 301 installed outside one end of the supporting ring 2. A handle 303 is hinged on the connecting seat 301. A connecting arm 302 is hinged in the middle of the handle 303, wherein the connecting arm The front end of 302 is provided with connecting shaft 306, and corresponding connecting shaft 306 is provided with hook seat 305 outside the other end of support ring 2, and hook seat 305 is provided with hook 307, and hook 307 forms connection relation with connecting shaft 306;

[0041] A fixed hook 304 is also provided behind the connecting seat 301 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com