Grating device and air flotation equipment with same

A grid and air flotation technology, applied in grease/oily substance/float removal devices, chemical instruments and methods, flotation water/sewage treatment, etc., to improve oil removal efficiency and reduce inlet power requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

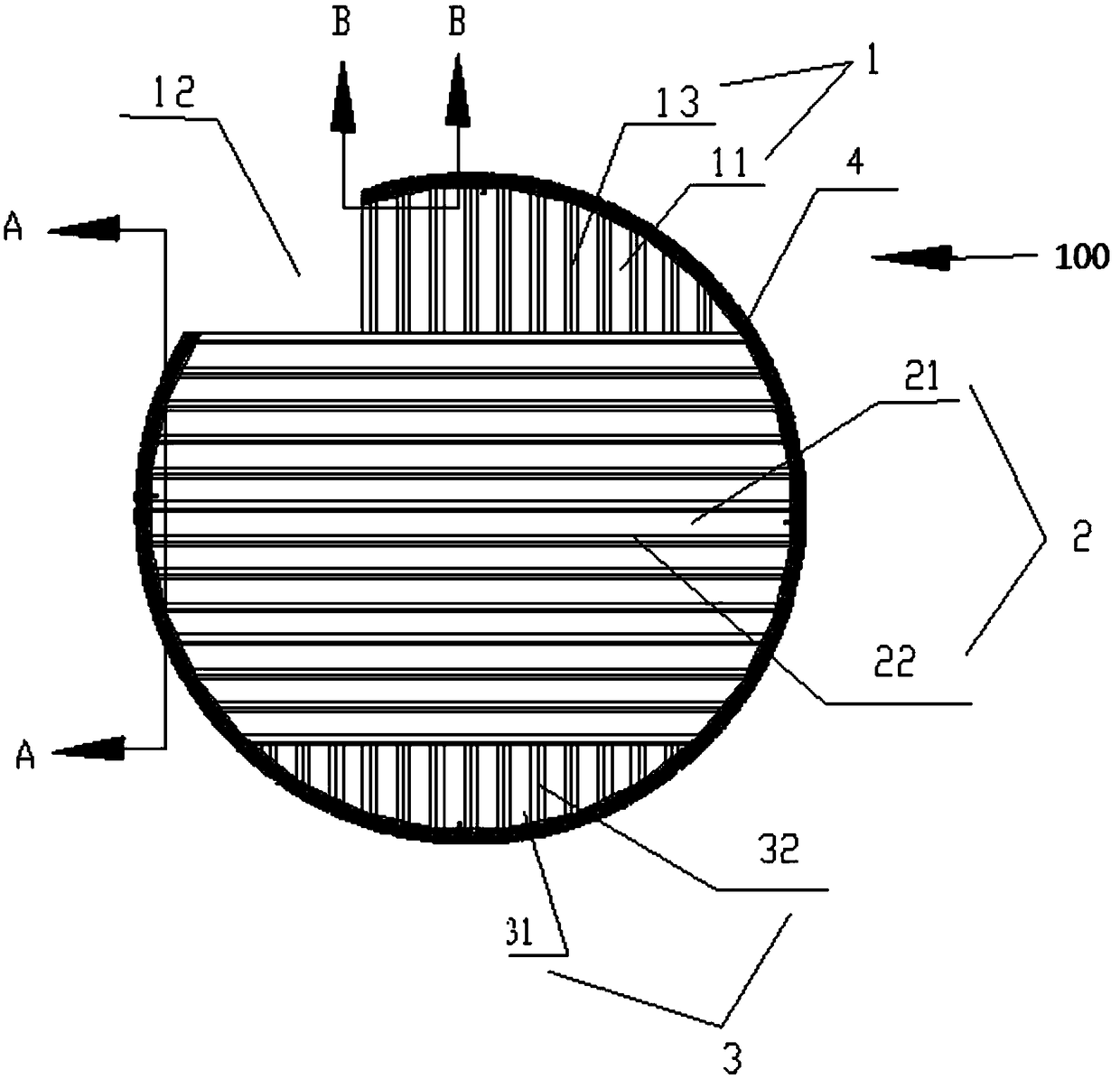

[0052] Such as Figure 1-10 As shown, a grid device 100 is installed in the cavity of the air flotation device, including:

[0053] The upper grid 1 has a number of first gaps 11 for the passage of the unrecovered dirty oil layer on the upper part of the air flotation device; and one end of the upper grid 1 is reserved with a gap 12 for installing the oil collection tank;

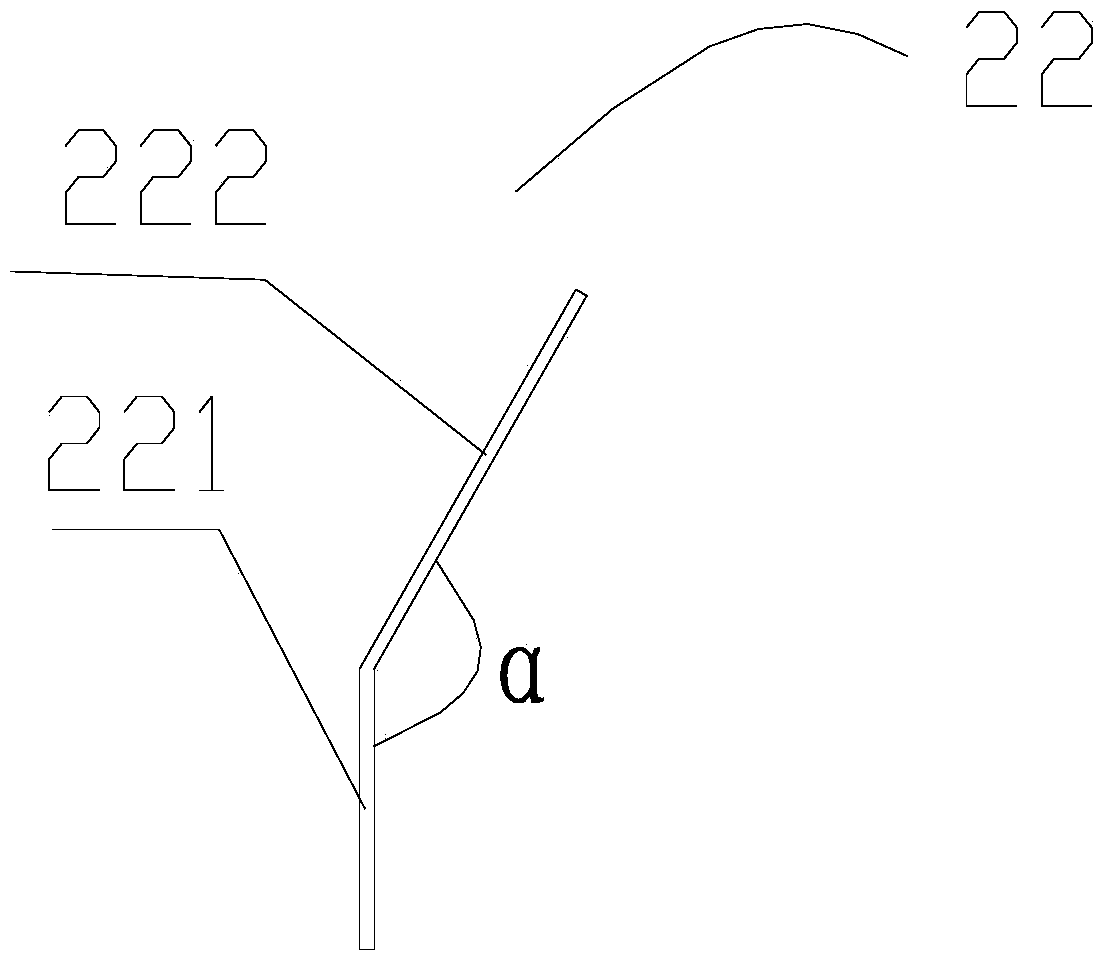

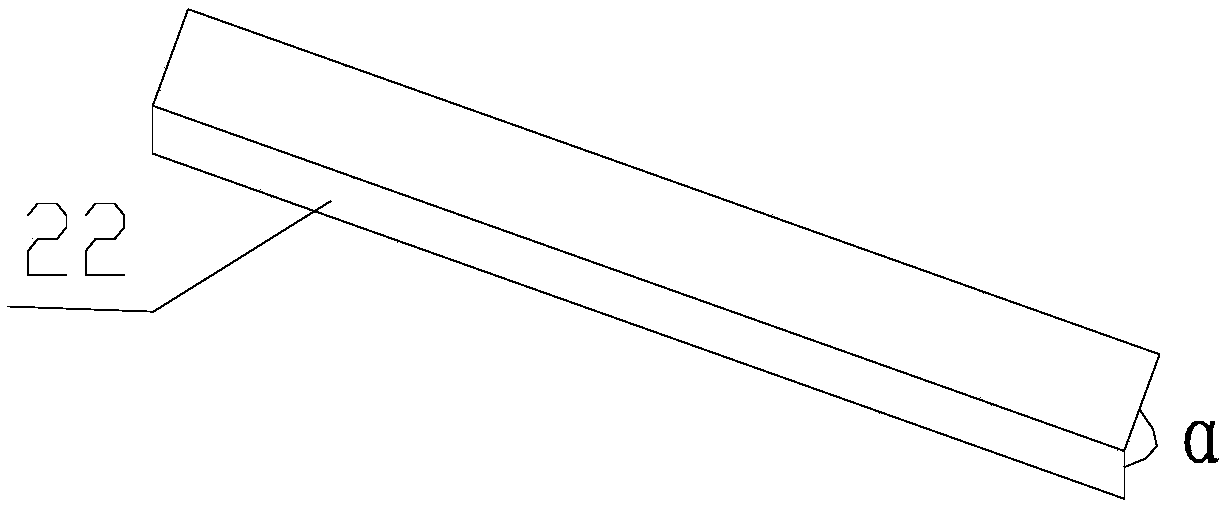

[0054] The middle grid 2 has a number of second gaps 21 for the liquid in the middle of the air flotation device to pass through, and the lower side of the second gap 21 is provided with an inclined surface; wherein, the liquid in the middle of the air flotation device When passing through the middle grid from the front side of the middle grid to the back side of the middle grid, move obliquely upward along the inclined surface and pass through the second gap;

[0055] The lower grid 3 has several third gaps 31 for the sediment layer at the bottom of the air flotation device to pass through;

[0056] The ...

Embodiment 2

[0105] Such as Figure 10 As shown, an air flotation device includes the above-mentioned grille device 100 and the oil collection tank 5. Several grille devices 100 are detachably installed in the cavity through the installation frame 4 and the cavity of the air flotation device is divided into several air tanks. In the floating chamber, the gaps 12 of each grid device are correspondingly arranged, and the oil collection tank 5 is installed on several of the gaps 12 .

[0106] Specifically, the installation frame 4 is connected with the reserved circumferential steel plate on the inner wall of the air flotation device through bolts.

[0107] Specifically, the air flotation device is also provided with an inspection port 14, a water inlet 6, a return water inlet 7, a water outlet 8, a return water outlet 9 and an oil collection port 10. The existing horizontal multi-chamber air flotation devices are all These components are provided, and will not be described in detail here. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com