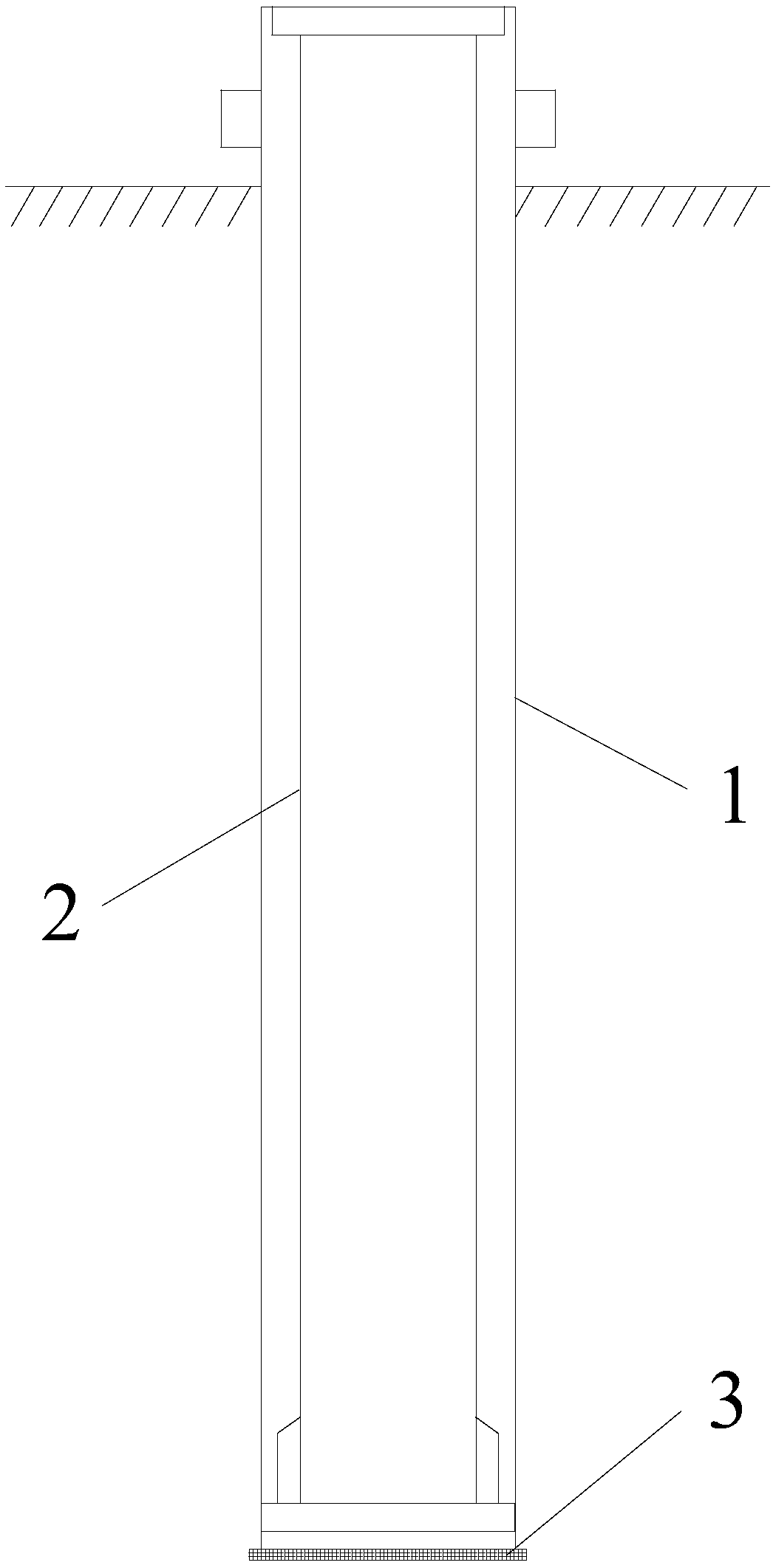

Pile-forming method of cast-in-place pile with internal ramming and enlarging sinking pipe in deep clay stratum

A technique of sinking pipe grouting piles and clay layers, which is applied in the direction of soil protection, sheet pile walls, construction, etc., and can solve problems such as the failure to form the expansion head, mud entering the pipe, affecting the construction progress and pile quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] In this embodiment, in step D, the outer tube 1 is slowly lifted while being tamped. In step E, the outer tube 1 is slowly lifted while tamping. While the bulk material is being driven in, the outer pipe 1 should be lifted slowly to avoid breaking down the cohesive soil and causing its properties to be destroyed, thereby causing mud to enter the nozzle.

Embodiment 2

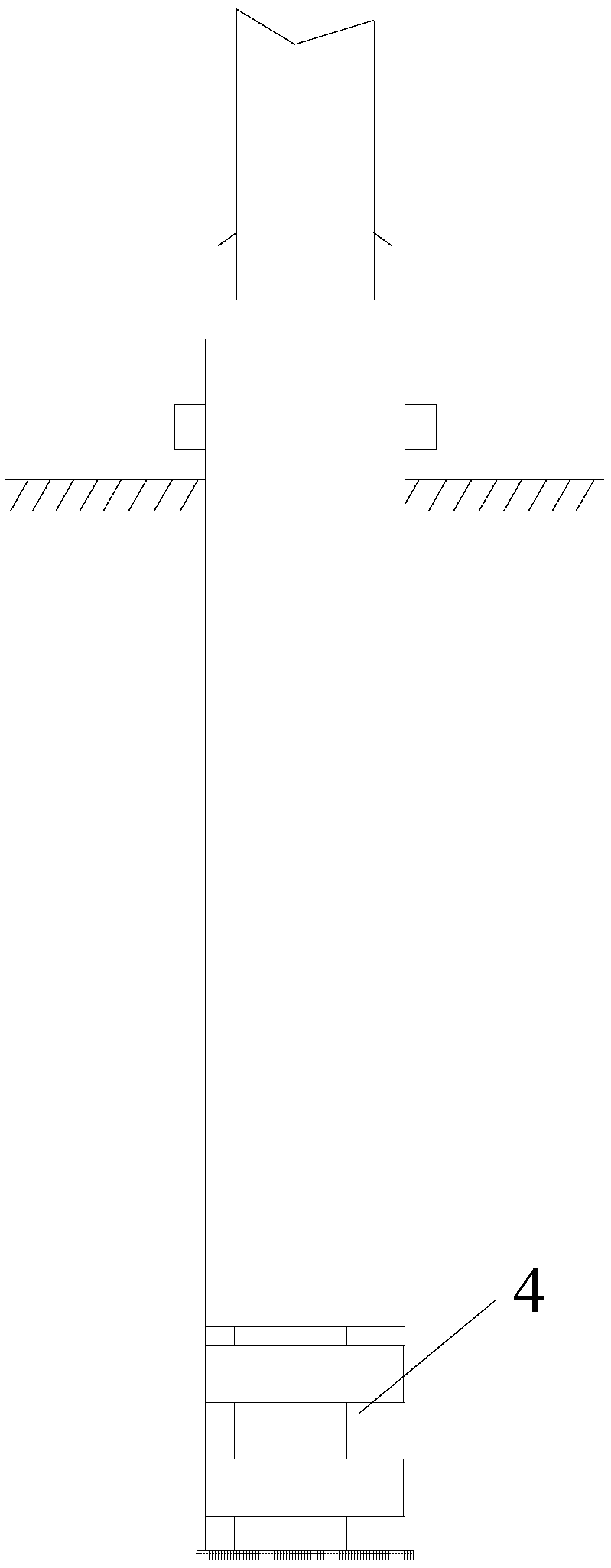

[0040] In this embodiment, in step D, if the amount of broken bricks to be rammed is large, the method of tamping in batches can be adopted to avoid excessive lateral resistance caused by the outer tube 1, thereby affecting the quality of the pile.

Embodiment 3

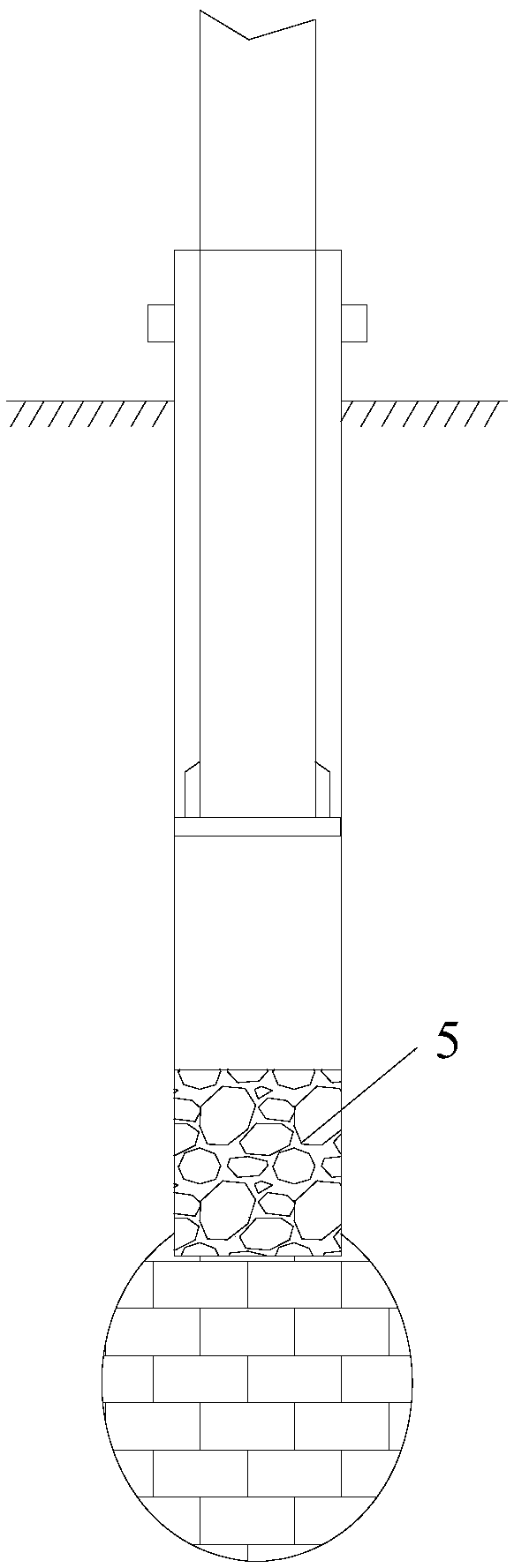

[0042] In this embodiment, the cumulative lifting height of the outer pipe 1 is monitored and controlled according to the actual conditions of the construction site, and the tamping is stopped when the penetration reaches the requirement. like Figure 4 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com