Efficient silicon removal device

A high-efficiency, coagulation technology, applied in the direction of special treatment targets, water pollutants, water/sewage treatment, etc., can solve the problem of low chemical utilization rate, affecting the system, coagulation flocculation tank and central diversion tube bottom mud accumulation and other problems, achieve the effects of obvious silicon removal effect, simple and quick maintenance, and reduce the probability of operation accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing and specific embodiment content of the present invention is described in further detail:

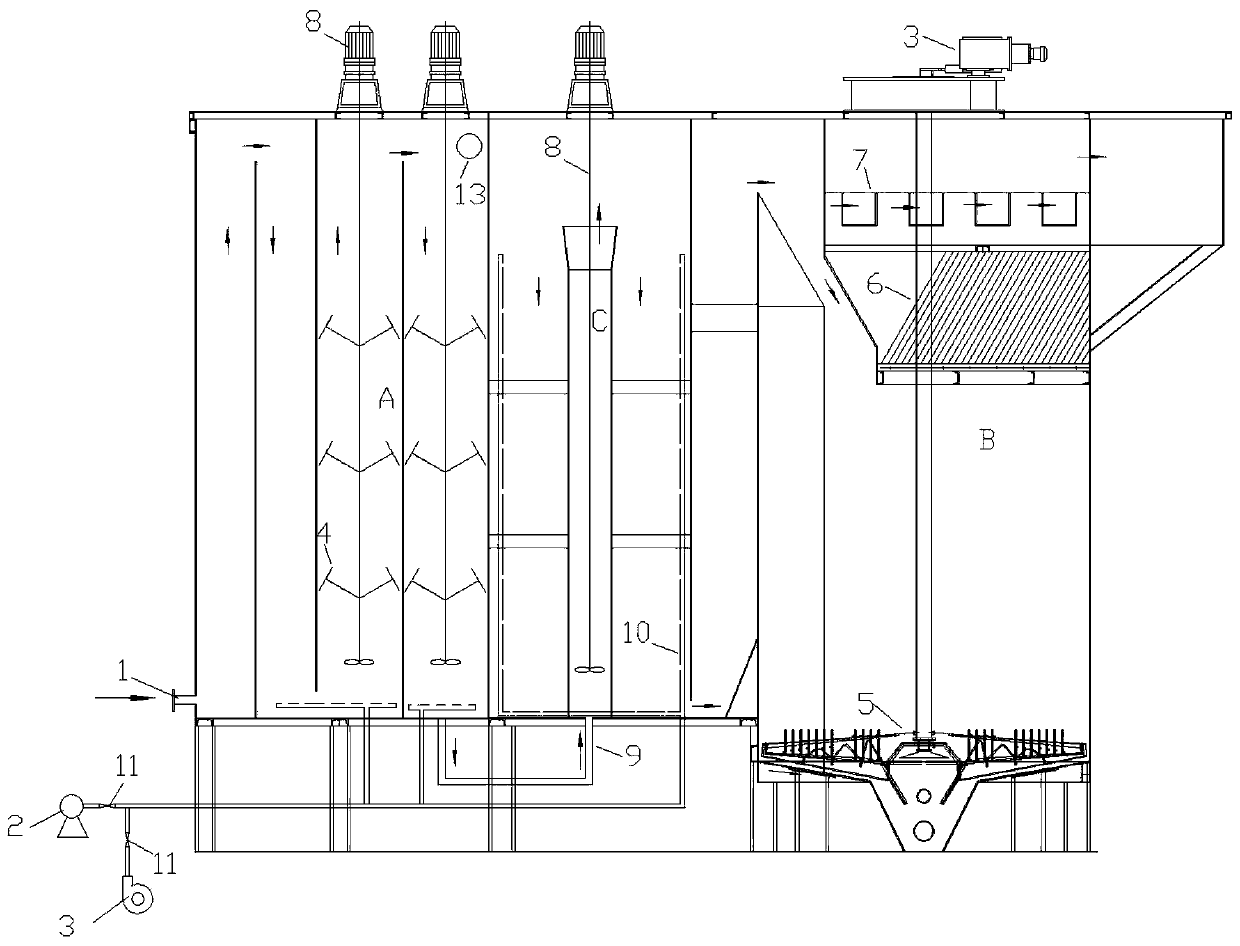

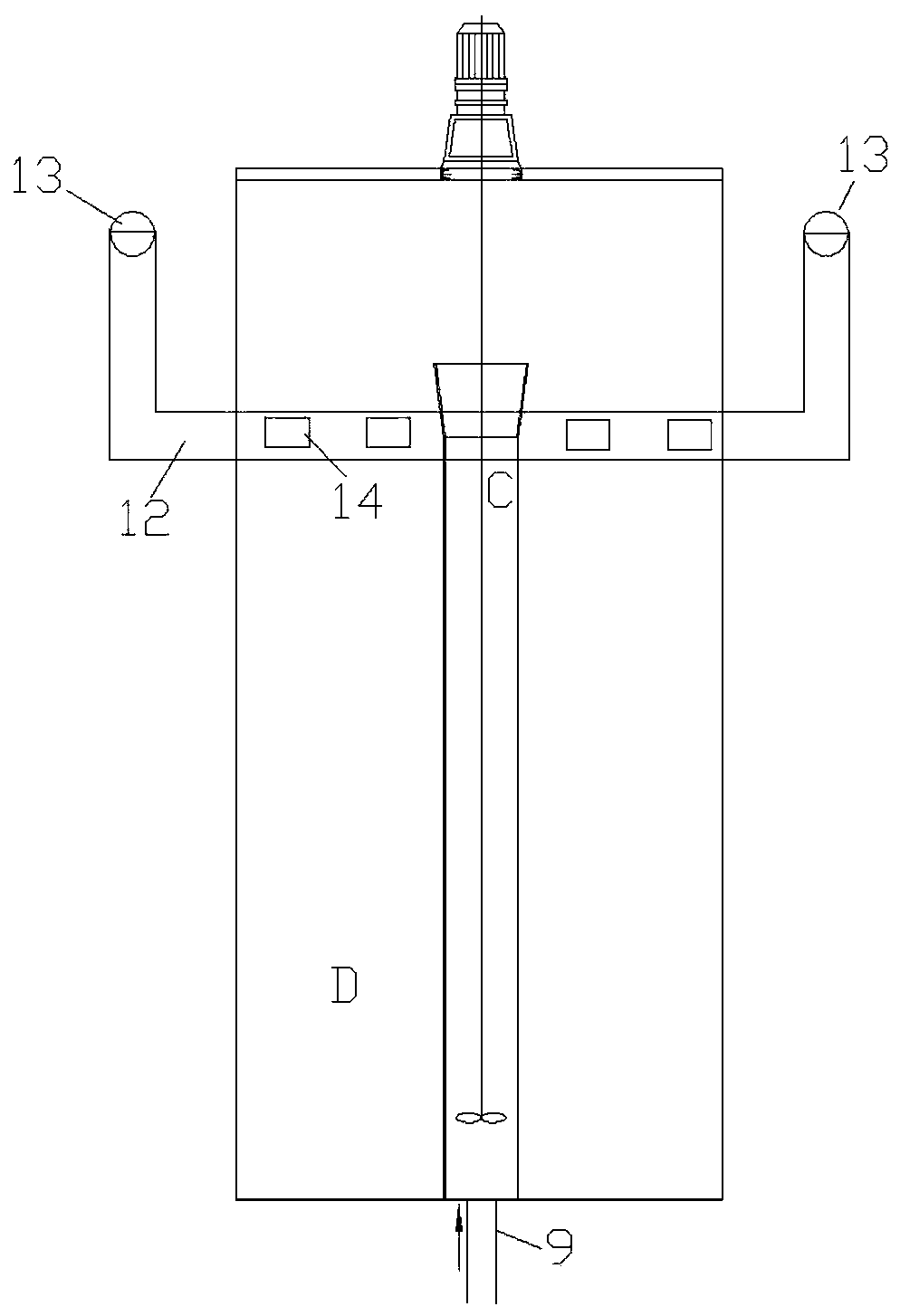

[0029] Such as Figure 1 to Figure 3 As shown, the high-efficiency silicon removal device includes a coagulation and flocculation tank A, a central guide tube C, an adjacent area D of the central guide tube, and a sedimentation tank B that are sequentially connected along the water flow direction. In addition, it also includes a T-shaped inclined plate 4, an overflow pipe 12 and a backwashing unit.

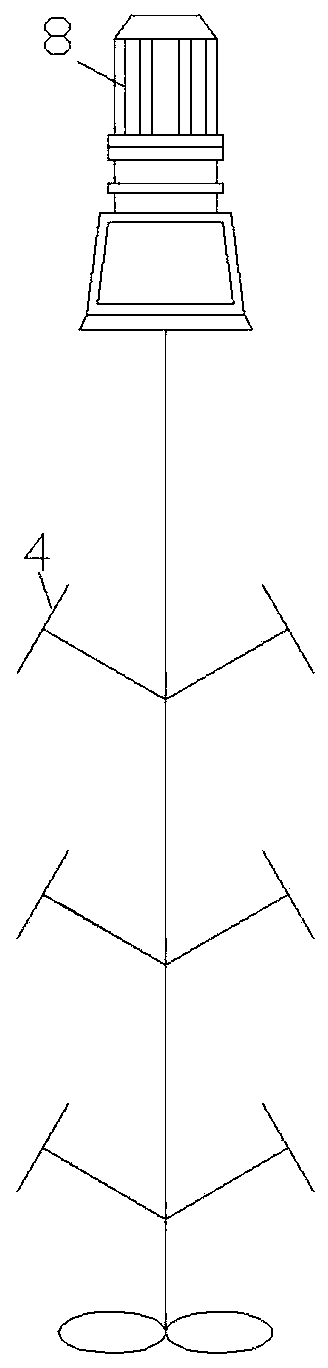

[0030] The coagulation and flocculation tank A is continuously provided with a plurality of vertical partitions, forming an "S"-shaped water flow channel in the horizontal direction, which is used to prolong the contact time between the high salt water and the chemical agent, and the area between adjacent partitions is equipped with a mixer 8 , the stirring shaft of each mixer 8 is provided with a T-shaped inclined plate 4, and the T-sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com