An evaporator defrosting and deicing assembly for cold storage

A technology of evaporators and components, applied in defrosting, household refrigeration devices, applications, etc., can solve problems such as unfavorable use of cold storage, waste of manpower and material resources, and affect the normal operation of cold storage, and achieve the effect of saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

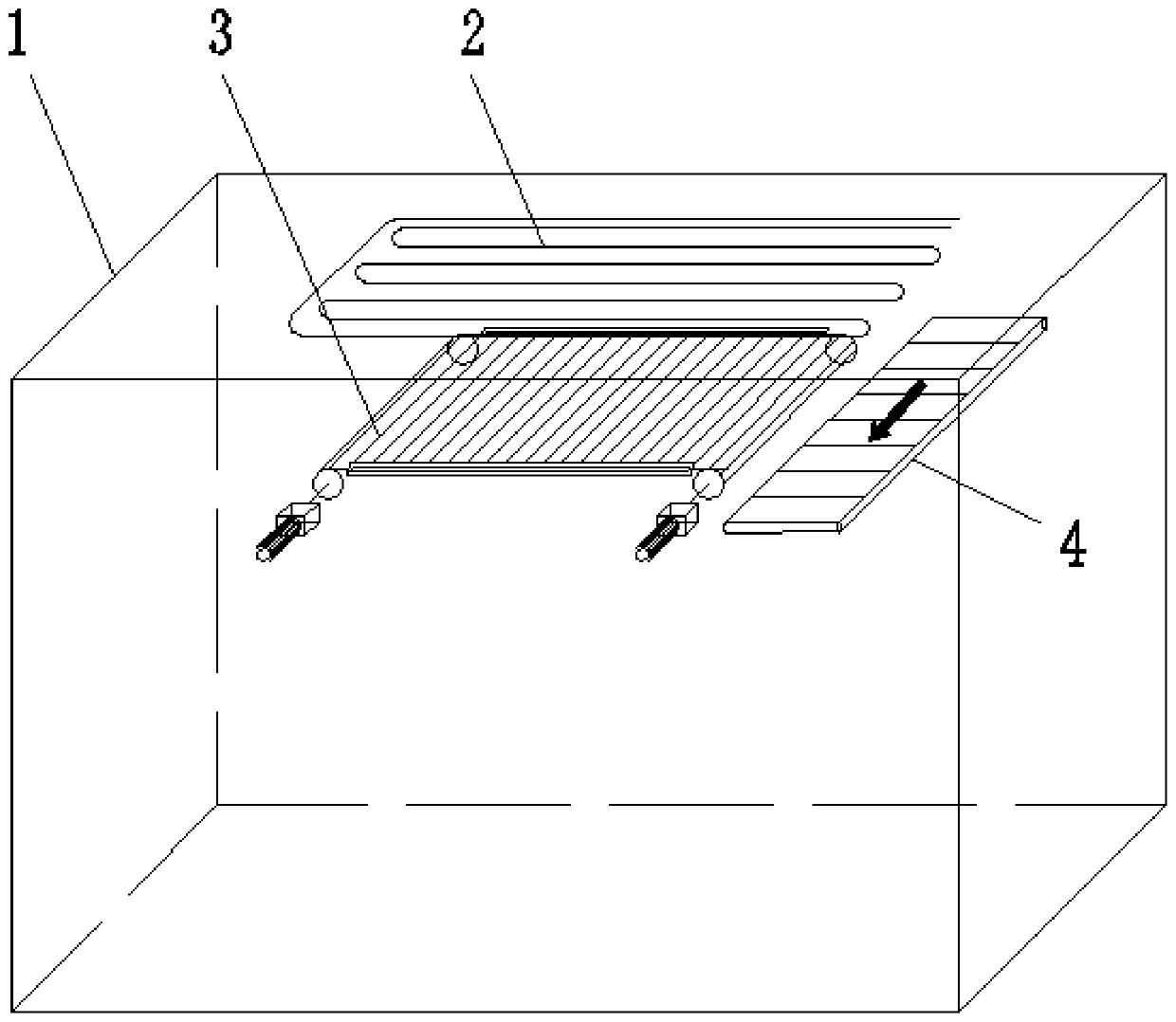

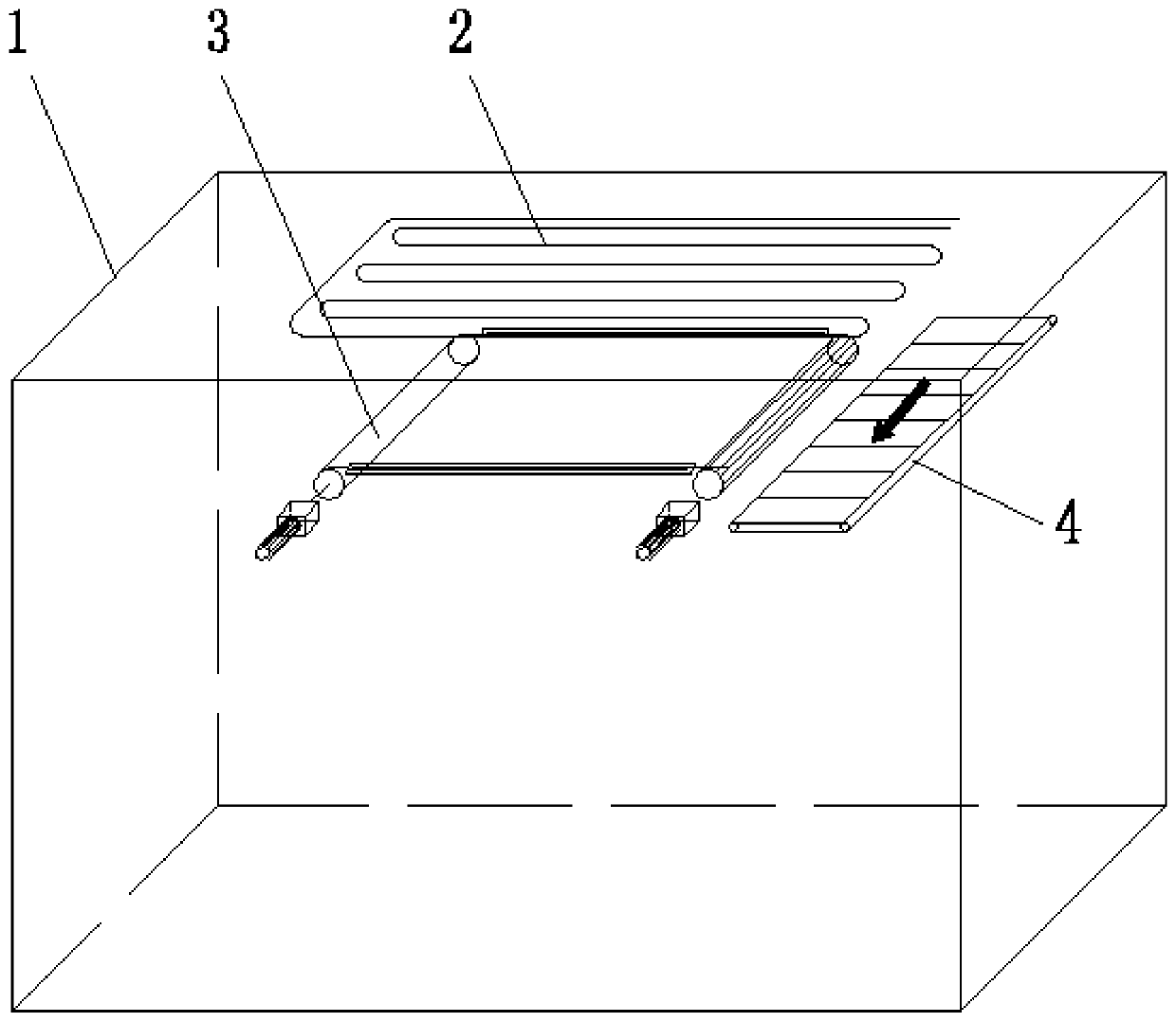

[0029] Specific implementation mode one, such as Figure 1 to Figure 5 As shown, the evaporator defrosting and deicing assembly of the present invention includes a cold storage 1 and an evaporator 2 installed on the roof of the cold storage 1, and also includes at least one crushed ice removal device 3, which is located at the evaporator 2 directly below.

specific Embodiment approach 2

[0030] Specific embodiment two, a conveying belt 4 is arranged below the end of the crushed ice removal device 3, and a crushed ice collecting tank is arranged at the end of the conveying belt 4, and the transmission mode of the crushed ice removal device 3 is a chain drive, a belt drive or a traction rope transmission. During defrosting, the crushed ice falls on the crushed ice removal device 3, and is transported to the conveyor belt 4 by the crushed ice removal device 3, and is collected into the crushed ice collection tank by the conveyor belt 4 for centralized cleaning and transportation.

specific Embodiment approach 3

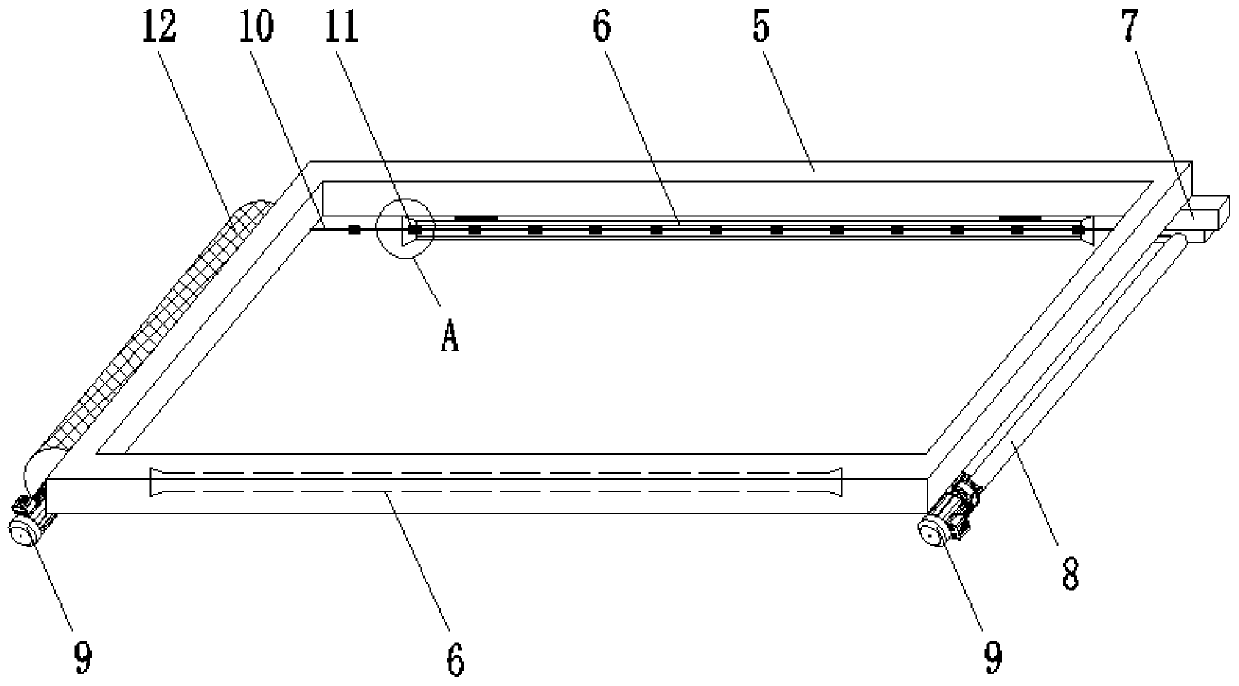

[0031] Specific embodiment three, the crushed ice removal device 3 includes a frame 5, a hoisting drive assembly and a crushed ice receiving device; the two longitudinal side walls of the frame 5 are equipped with a hoisting drive assembly, and the output of the two hoisting drive assemblies The ends are connected by a crushed ice receiving device. The crushed ice receiving device is wound on one of the winch drive components, and drives the other winch drive component when in use, so that the crushed ice receiving device is wound onto the other winch drive component, and the crushed ice is cleared and transported at the same time;

[0032] The crushed ice receiving device is a high-strength cloth 12 made of textiles or plastics or metal or nanomaterials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com