Spark plug

A spark plug and cavity technology, applied in the field of measurement, can solve the problems of high cost, uneconomical, and large errors of high-precision equipment, and achieve the effect of simple structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

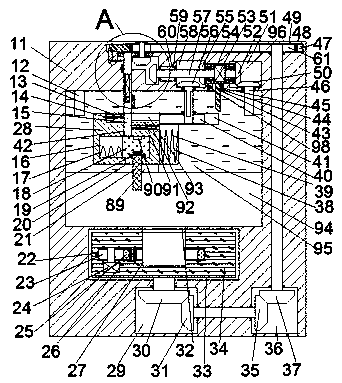

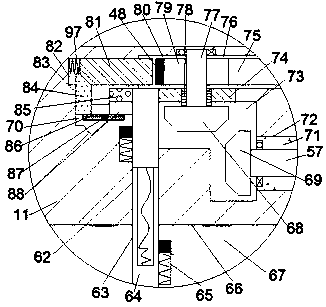

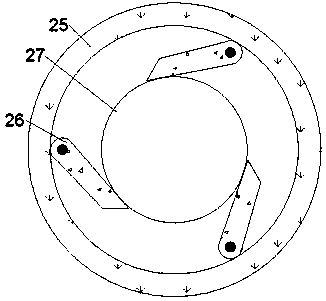

[0012] Combine below Figure 1-3 The present invention will be described in detail.

[0013] refer to Figure 1-3, a spark plug according to an embodiment of the present invention, comprising a device body 11, a transmission device disposed in the device body 11, a clamping device disposed in the device body 11, and a device body 11 The test device, the transmission device includes a first cavity 94 arranged in the device main body 11, a first slider 95 is slidably arranged in the first cavity 94, and the test device is arranged in the In the first slider 95, a second cavity 51 is arranged in the upper inner wall on the right side of the first cavity 94, and a first bevel gear 50 is rotatably arranged in the second cavity 51, The lower end of the first bevel gear 50 is fixedly connected with a screw rod 46, and the lower end of the screw rod 46 extends into the first slider 95 and is threadedly connected with the first slider 95. A second bevel gear 52 meshing with the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com