9/8-pole switched reluctance motor

A technology of reluctance motor and pole switch, applied in asynchronous induction motor, magnetic circuit, electric components, etc., can solve the problems of three-phase 12/8 pole switched reluctance motor torque ripple and large core loss, etc., and reach the output range Large, small core loss, strong starting ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

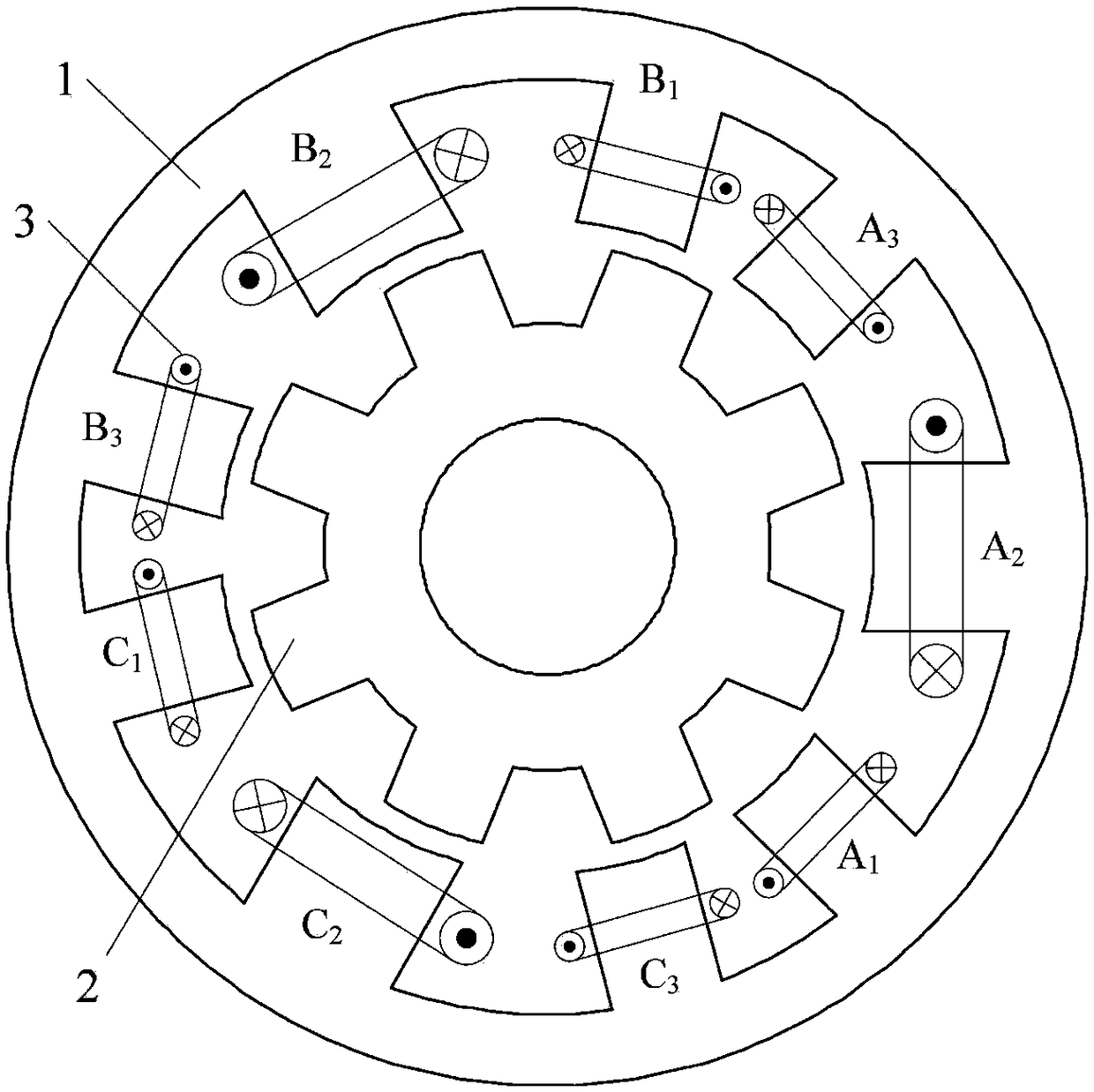

[0022] Below in conjunction with accompanying drawing, the technical scheme of a kind of 9 / 8 pole switched reluctance motor of the present invention is described in detail:

[0023] Such as figure 1 Shown is the two-dimensional structural diagram of the motor of the present invention, wherein, 1 is a stator, 2 is a rotor, 3 is a coil, and A 1 、A 2 、A 3 , B 1 , B 2 , B 3 、C 1 、C 2 、C 3 are stator teeth respectively, A 2 , B 2 、C 2 For wide teeth, A 1 、A 3 , B 1 , B 3 、C 1 、C 3 for narrow teeth.

[0024] The 9 / 8-pole switched reluctance motor is a three-phase motor, including a stator, a rotor and a coil;

[0025] The stator is a salient pole structure, the number of stator teeth is 9, and the 9 stator teeth are respectively A in the counterclockwise direction 1 、A 2 、A 3 , B 1 , B 2 , B 3 、C 1 、C 2 、C 3 , where A 2 , B 2 、C 2 For wide teeth, A 1 、A 3 , B 1 , B 3 、C 1 、C 3 are narrow teeth; the tooth widths of the three wide teeth are equal, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com