Cleaning processing method of surface of large-diameter precise optical element

A technology of precision optics and processing methods, applied in chemical instruments and methods, cleaning methods and utensils, cleaning methods using tools, etc., can solve the problem that the surface of large-diameter optical components is easy to deliquesce, and cannot completely remove component polishing powder and solid substances, etc. problems, to achieve the effect of reducing the possibility of contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: A method for cleaning the surface of a large-caliber precision optical element, comprising the following steps:

[0025] S1) Pretreatment of polished large-diameter precision optical components: After the large-diameter precision optical components are polished, use a cleaning tool to remove the remaining polishing powder and solid stains on the edge of the large-diameter precision optical components; the cleaning tool can be soft Long fiber cloth or satin cloth;

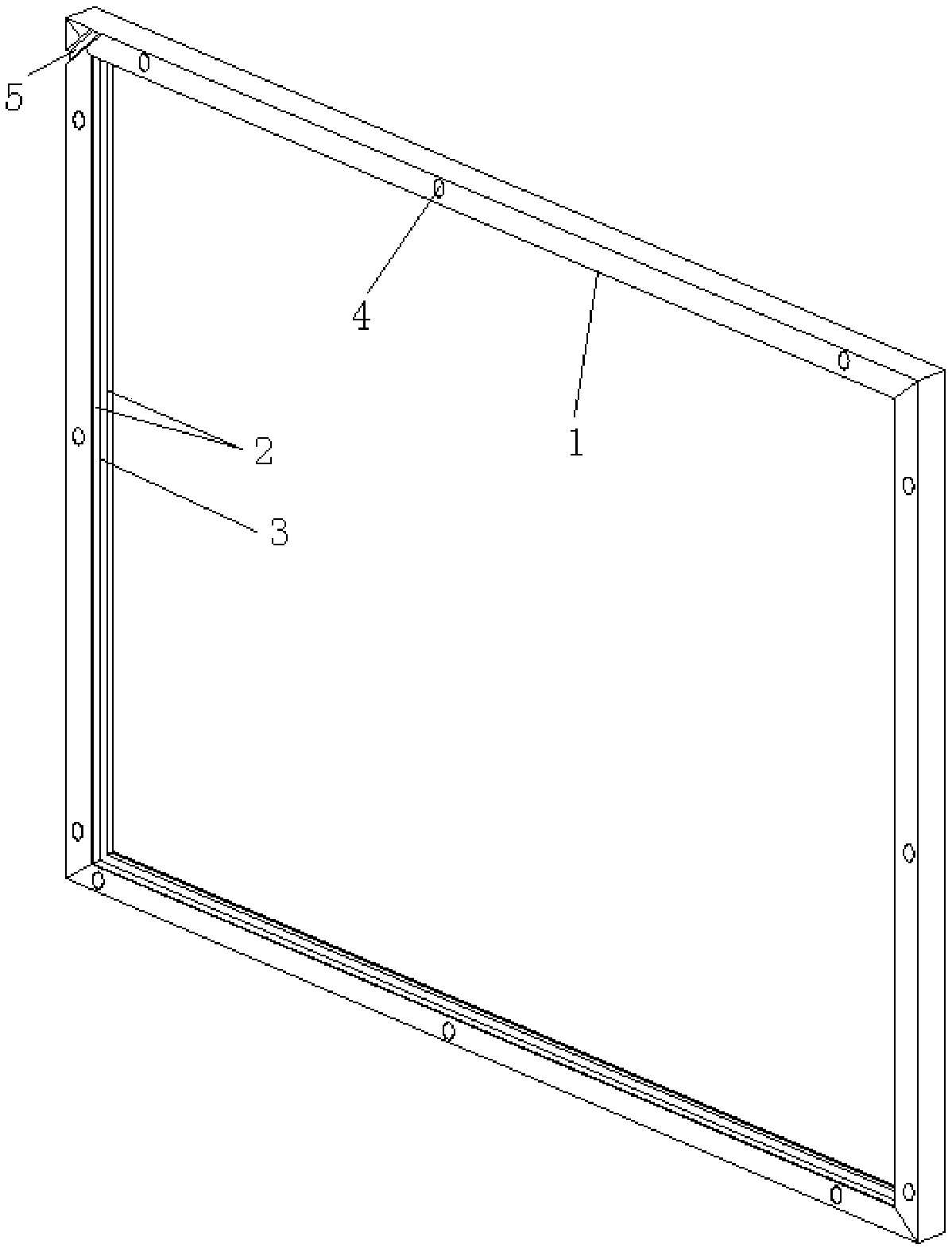

[0026] S2) Pre-fixation of the large-diameter precision optical element: the large-diameter precision optical element after step S1) is pre-fixed on a square frame, and the edge of the large-diameter precision optical element is embedded in the square frame; the inner frame of the square frame has Fixed groove, the product is embedded in the fixed groove, and will be processed together with the square frame during the whole cleaning process;

[0027] S3) On-line delivery of the large-diameter p...

Embodiment 2

[0033] Embodiment 2: A method for cleaning the surface of a large-diameter precision optical element, comprising the following steps:

[0034] S1) Pretreatment of polished large-diameter precision optical components: After the large-diameter precision optical components are polished, use a cleaning tool to remove the remaining polishing powder and solid stains on the edge of the large-diameter precision optical components; the cleaning tool can be soft Long fiber cloth or satin cloth;

[0035] S2) Pre-fixation of the large-diameter precision optical element: the large-diameter precision optical element after step S1) is pre-fixed on a square frame, and the edge of the large-diameter precision optical element is embedded in the square frame; the inner frame of the square frame has Fixed groove, the product is embedded in the fixed groove, and will be processed together with the square frame during the whole cleaning process;

[0036] S3) On-line delivery of the large-diameter ...

Embodiment 3

[0042] Embodiment 3: A method for cleaning the surface of a large-caliber precision optical element, comprising the following steps:

[0043] S1) Pretreatment of polished large-diameter precision optical components: After the large-diameter precision optical components are polished, use a cleaning tool to remove the remaining polishing powder and solid stains on the edge of the large-diameter precision optical components; the cleaning tool can be soft Long fiber cloth or satin cloth;

[0044] S2) Pre-fixation of the large-diameter precision optical element: the large-diameter precision optical element after step S1) is pre-fixed on a square frame, and the edge of the large-diameter precision optical element is embedded in the square frame; the inner frame of the square frame has Fixed groove, the product is embedded in the fixed groove, and will be processed together with the square frame during the whole cleaning process;

[0045] S3) On-line delivery of the large-diameter p...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap