Cutting and grinding device for round steel production

A round steel and grinding technology is applied in the field of cutting and grinding devices for round steel production, which can solve the problems of inconvenient waste collection and removal of metal dust, single function, and inconvenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

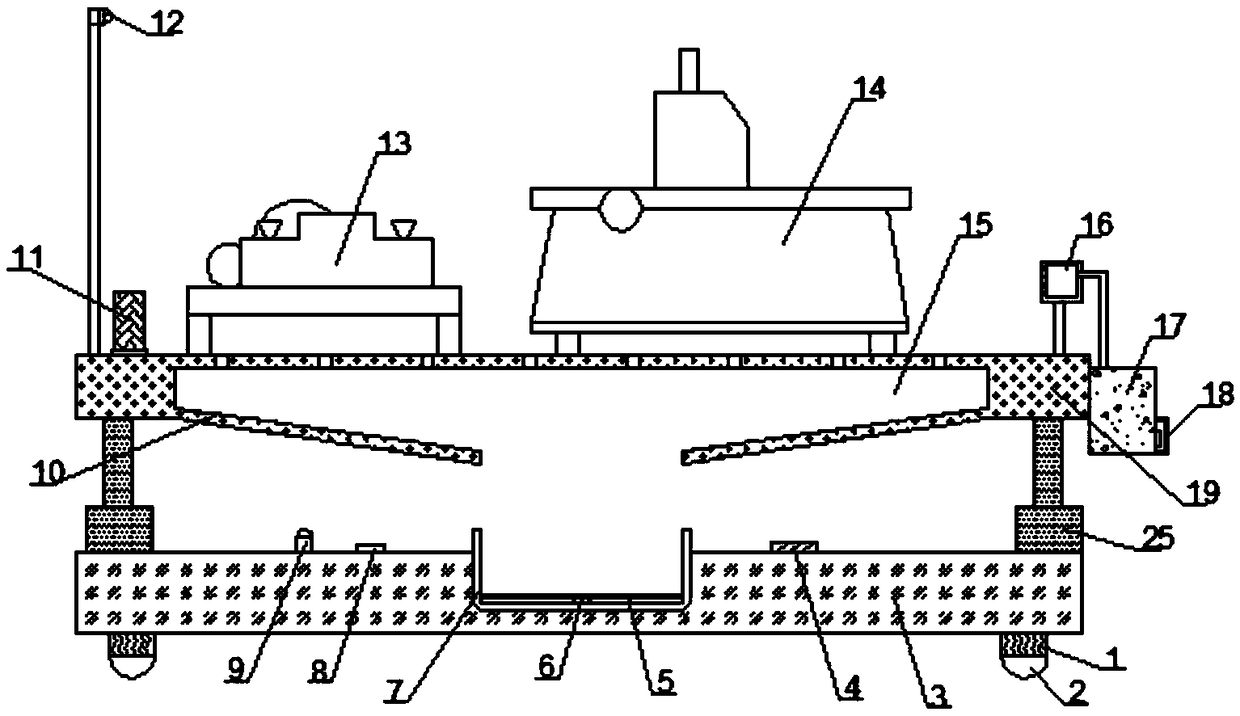

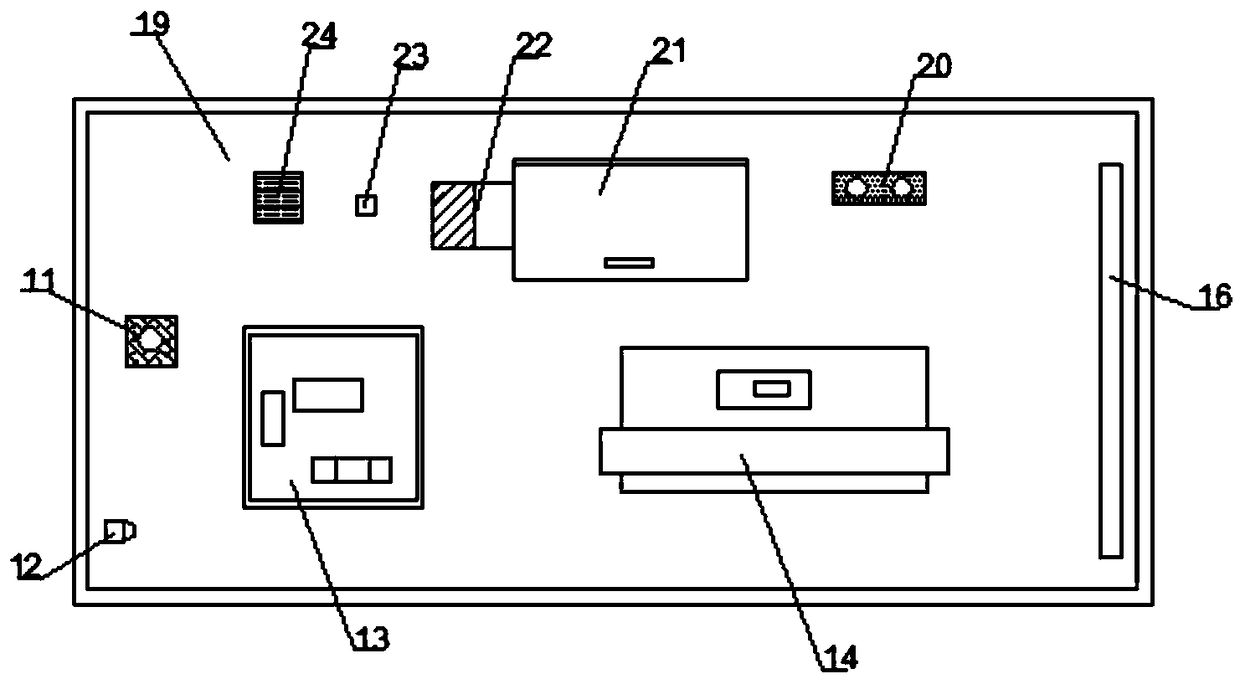

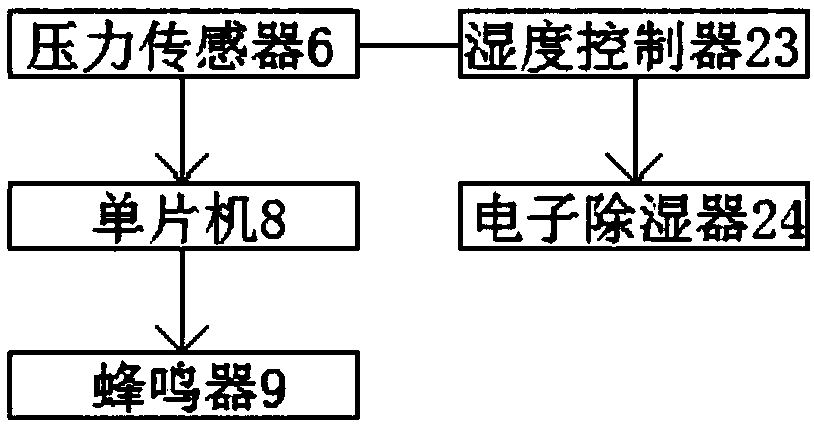

[0023] Such as Figure 1-3 Shown, a kind of cutting grinding device for round steel production, including base 3, workbench 19 and grinding machine 14, described base 3 top is provided with mounting groove and collecting box 7 is installed in the mounting groove, in described collecting box 7 The bottom is connected with a pressure sensor 6 through a connector and the pressure sensor 6 is electrically connected with the single-chip microcomputer 8. One side of the collection box 7 is connected with an electronic insect repellent 4 through a bolt, and the other side of the collection box 7 is connected with a A single-chip microcomputer 8, a buzzer 9 is arranged on one side of the single-chip microcomputer 8, and the two ends of the top of the base 3 are connected to the electric hydraulic cylinder 25 by bolts, and the output end of the electric hydraulic cylinder 25 is connected to the workbench 19, and the workbench 19 A hollow cavity 15 is arranged inside, a fan 17 is instal...

Embodiment 2

[0031] Such as Figure 1-3 Shown, a kind of cutting grinding device for round steel production, including base 3, workbench 19 and grinding machine 14, described base 3 top is provided with mounting groove and collecting box 7 is installed in the mounting groove, in described collecting box 7 The bottom is connected with a pressure sensor 6 through a connector and the pressure sensor 6 is electrically connected with the single-chip microcomputer 8. One side of the collection box 7 is connected with an electronic insect repellent 4 through a bolt, and the other side of the collection box 7 is connected with a A single-chip microcomputer 8, a buzzer 9 is arranged on one side of the single-chip microcomputer 8, and the two ends of the top of the base 3 are connected to the electric hydraulic cylinder 25 by bolts, and the output end of the electric hydraulic cylinder 25 is connected to the workbench 19, and the workbench 19 A hollow cavity 15 is arranged inside, a fan 17 is instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com