An electronic production process for a crosslinked polyethylene vibration-attenuating composite floor board

A composite flooring and production process technology, applied in the direction of layered products, lamination devices, lamination, etc., can solve the problem of single function, etc., and achieve the effect of strong overall sense, convenient cleaning, and small joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

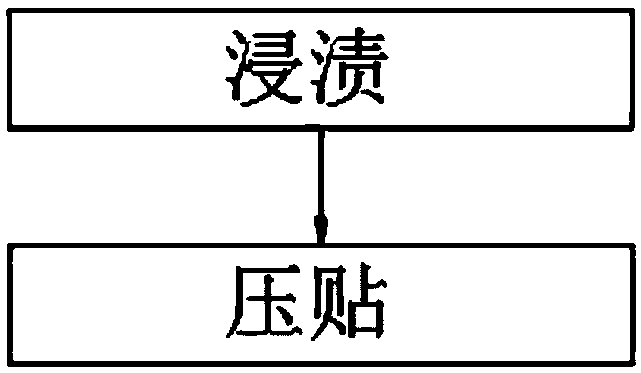

[0018] Example: such as figure 1 As shown, the present invention provides a kind of electronic cross-linked polyethylene vibration-damping composite floor production process, comprising the following steps:

[0019] 1) Impregnation. All kinds of impregnated papers are required to be stacked and stored in a room with constant temperature and humidity. The storage period generally does not exceed half a year. The impregnated papers are available in two sizes: 4×8 feet and 8×8 feet;

[0020] 2) Pressing: place the impregnated paper and the substrate in different layers, and send them to a low-pressure short-cycle press for hot pressing. The heat transfer oil is heated by the boiler and enters the press to heat the upper and lower steel plates fixed on the press. Then put the three kinds of paper and the base board in order, and then put them into the press, set the temperature of the press at 170-210°C, the pressure of the press at 18-23MPa and the holding time of 30±5S, 25±5S fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com