Raster motion control structure

A motion structure, grating technology, applied in printing, printing device and other directions, can solve the problem of grating easy to accumulate dust, affecting the accuracy of grating and grating reading head, etc., to achieve the effect of simple support structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

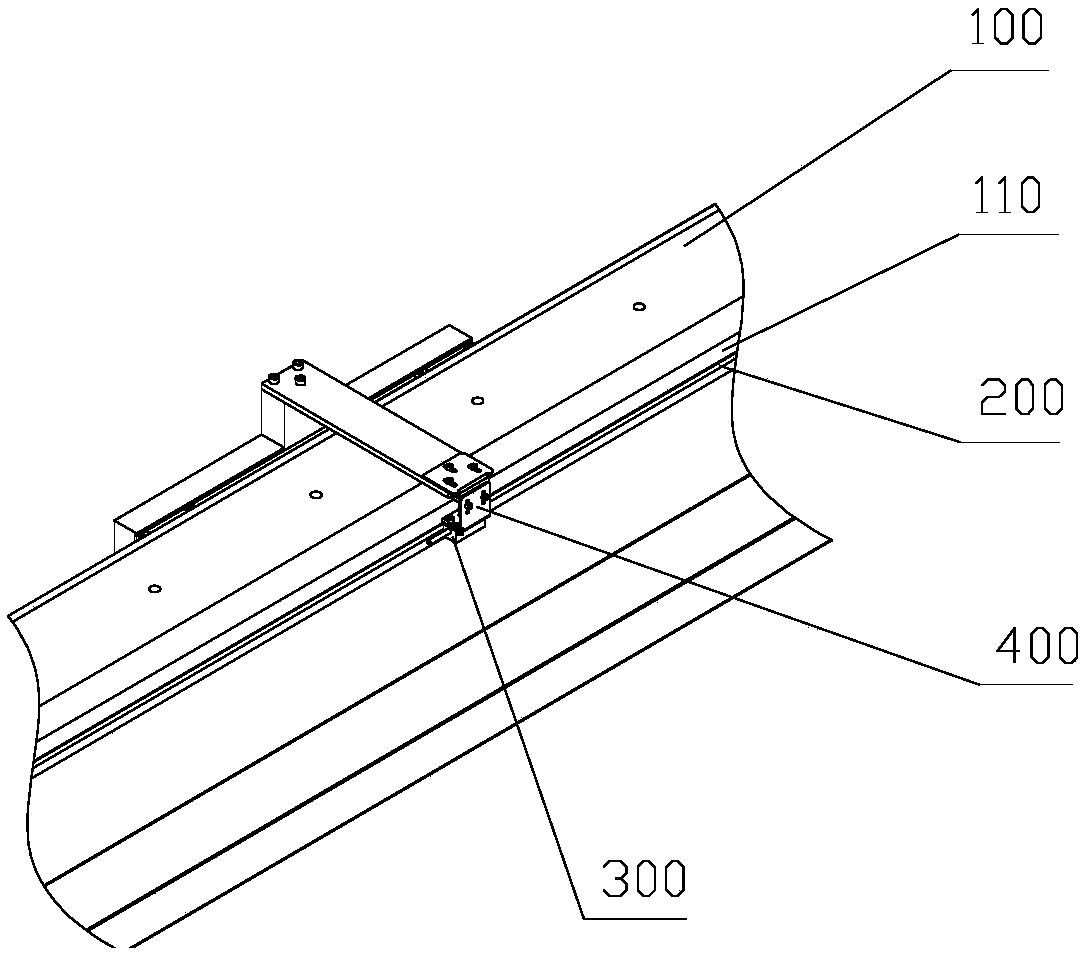

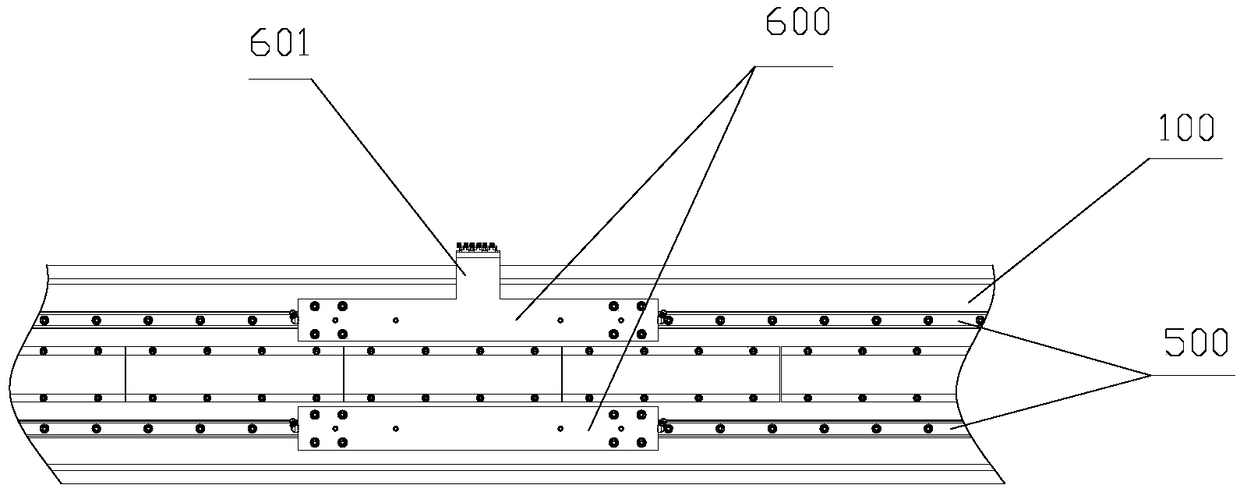

[0027] like Figure 1 to Figure 4 As shown, the grating control movement structure includes a main body 100 , a grating 200 , a grating reading head 300 , a bracket 400 and a sliding device 500 .

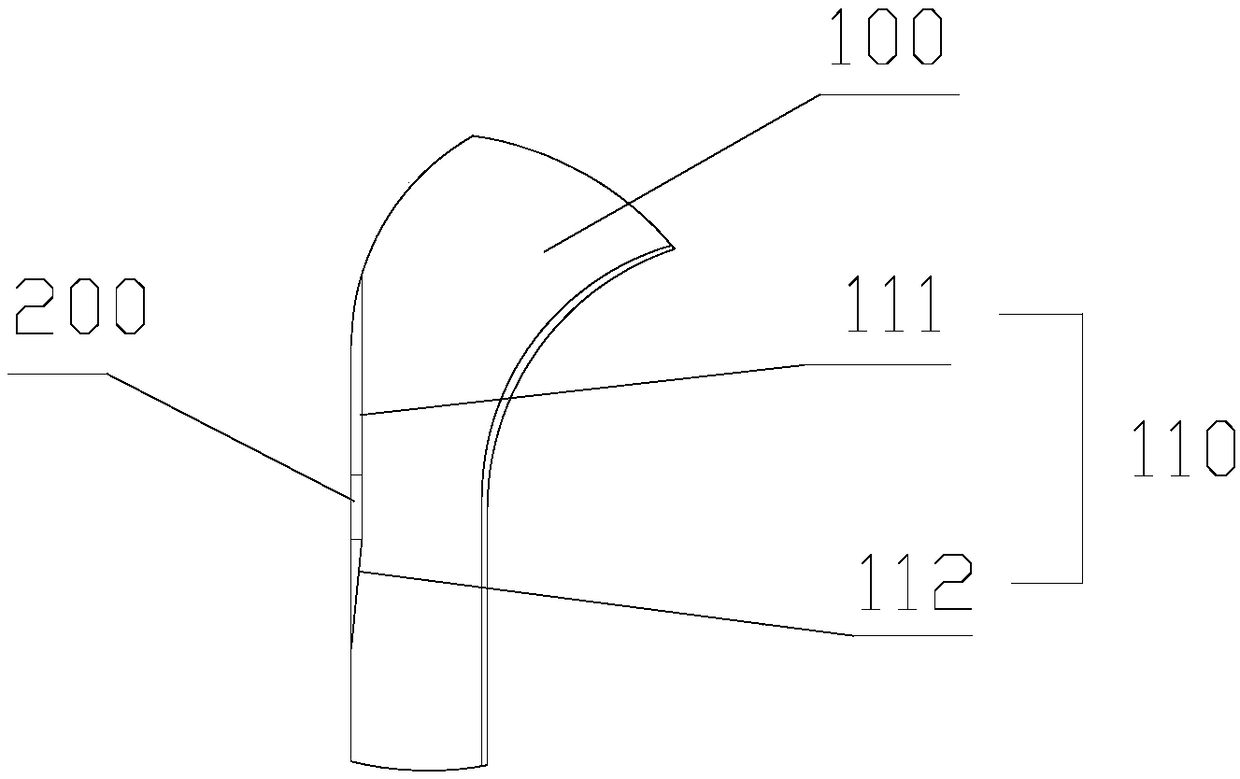

[0028] like figure 1 and image 3 As shown, one side of the body 100 is provided with a mounting groove 110, the mounting groove 110 includes a mounting surface 111 and an inclined surface 112, the mounting surface 111 is used to install the grating 200, and the grating 200 is installed vertically, and the inclined surface 112 is located on the mounting surface The lower part of 111 is used for guiding dust to prevent dust from accumulating in the installation groove 110, thereby affecting the use of the grating 200. Wherein, the included angle between the installation surface 111 and the inclined surface 112 is 150°-190°, preferably, the included angle between the installation surface 111 and the inclined surface 112 is 175°.

[0029] The sliding device 500 is installed on the b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com