Printing control system

A printing control and controller technology, applied in printing devices, printing and other directions, can solve problems such as aging of mechanical parts and electronic components, paper jams, and impact on printing quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

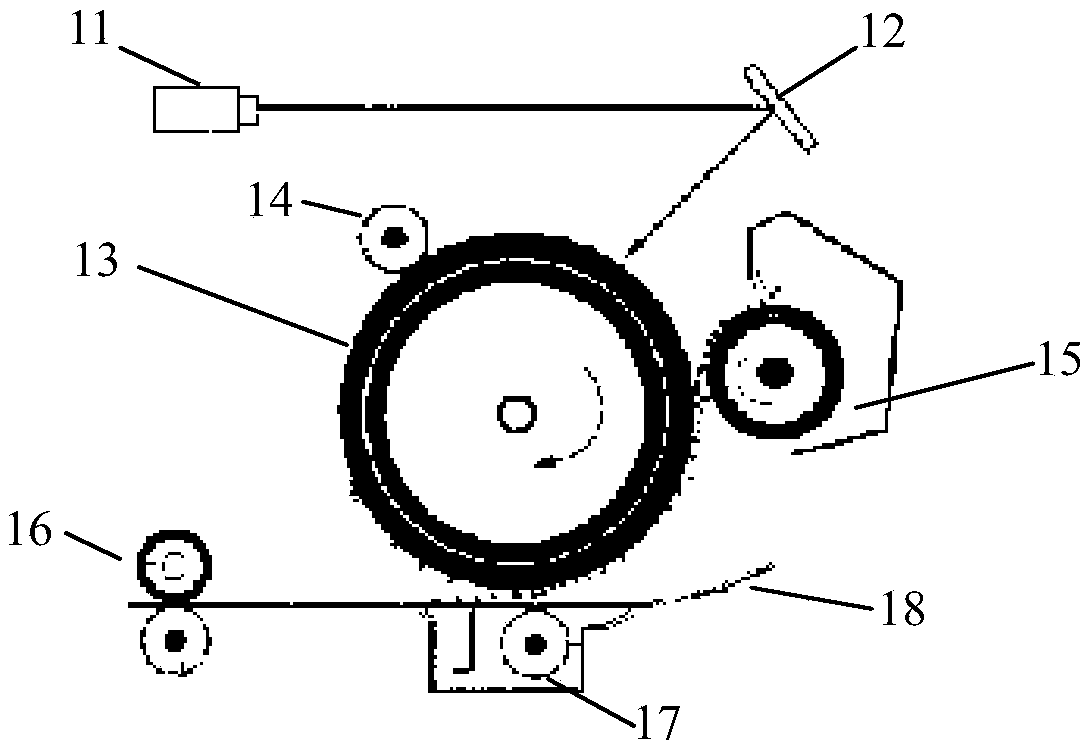

[0028] figure 1 A schematic diagram showing the working principle of a typical laser printer. Such as figure 1 As shown, the printer may include a laser 11 for emitting a laser beam; a mirror 12 for reflecting the laser beam to the photosensitive drum 13; a charging roller 14 for charging the printing roller 13; a developing roller 15; a pair of fixing rollers 16 (upper roller and lower roller); and transfer roller 17. After the printing paper 18 passes through the transfer roller 17, it is conveyed to a pair of fixing rollers 16. The fixing roller 16 is provided with a heating lamp (not shown). apart from figure 1 In addition to the components shown in the printer, the printer may also include other known components, such as a paper box, a paper feeding mechanism, and so on.

[0029] The printer may also include a control system, such as a controller, data interface, display, etc.

[0030] Since the printer needs to heat the printing paper during the printing process, when the ...

Embodiment 2

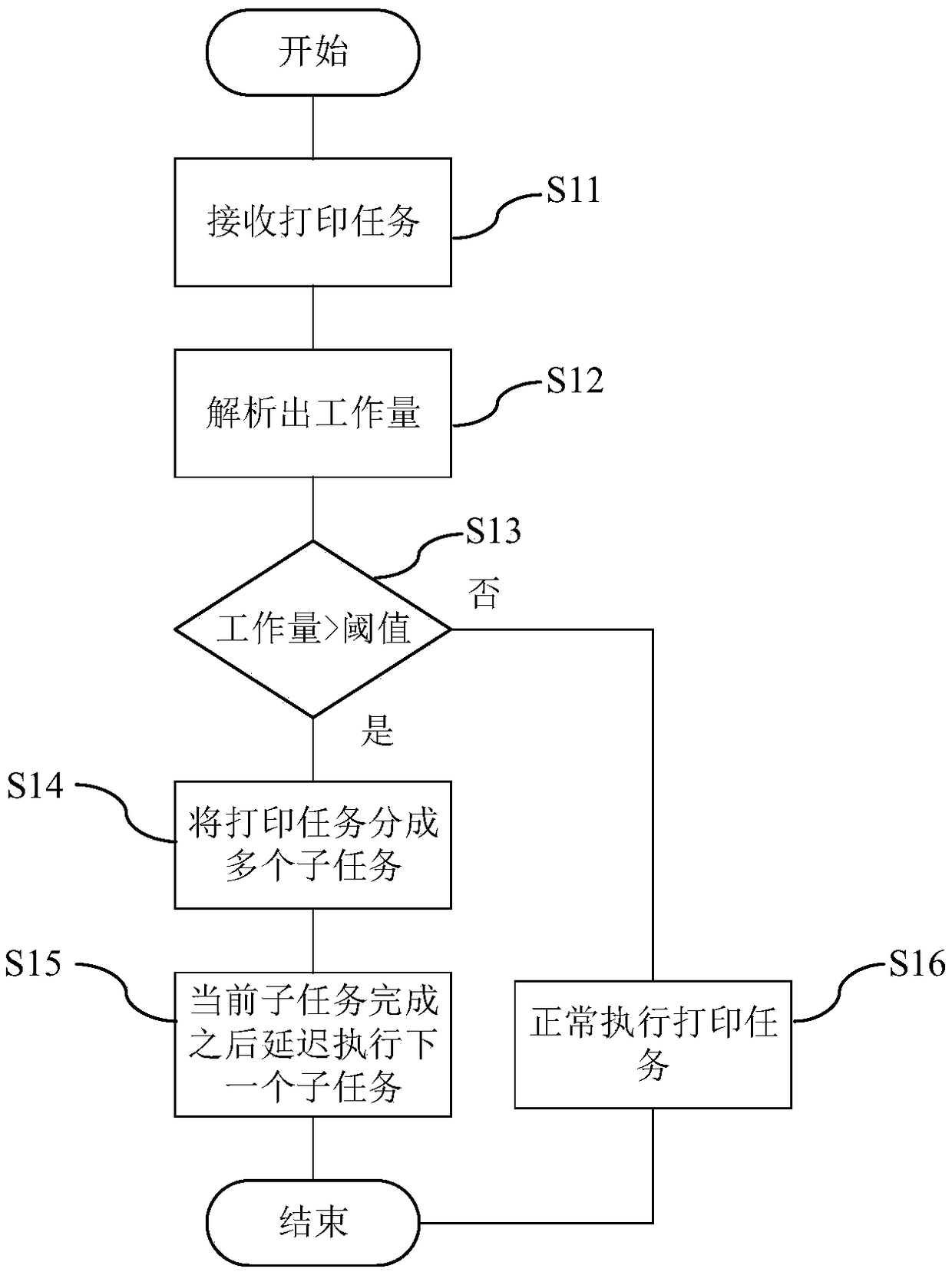

[0044] Figure 4 A flowchart of a control method according to an embodiment of the present invention is shown. Such as Figure 4 As shown, the printer variable speed temperature control method of the embodiment of the present invention includes the following steps:

[0045] 1) Establish a temperature-printing speed data table inside the printer;

[0046] 2) The temperature inside the printer is detected in real time, and the temperature-printing speed data table is searched according to the temperature inside the printer to obtain the printing speed to be adjusted;

[0047] 3) Control the printing speed of the internal printing unit (or printing mechanism) of the printer according to the printing speed to be adjusted.

[0048] In step 2), when searching the temperature-printing speed data table according to the temperature inside the printer to obtain the printing speed to be adjusted, if the temperature inside the printer exceeds the preset temperature threshold, an error message is ...

Embodiment 3

[0052] In addition to cooling by the printer control method in Embodiment 1, the temperature can also be lowered in other ways. Figure 5 Shows a schematic structural diagram of a printer according to an embodiment of the present invention. Such as Figure 5 As mentioned, in addition to the components that can be found in a typical printer, the printer may also include a ventilation device located in the paper output area of the printer. The ventilation device may include at least one air outlet 41 on the inner side of the paper output area of the printer and an air blowing device located inside the main body of the printer. The air blowing device may include, but is not limited to, a fan, an air pump, and the like. In an example, the shape of the air outlet 41 may be a slot on at least one side inside the paper outlet area. In another example, the shape of the air outlet 41 may be a plurality of air outlet holes on at least one side of the inner side of the paper discha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com