Logistics supply chain object automatic classifying system

A logistics supply chain and automatic classification technology, applied in the direction of conveyor objects, conveyor control devices, instruments, etc., can solve the problems of increasing costs, increasing classification costs, and low degree of automation, so as to save costs, save manpower, and save labor Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

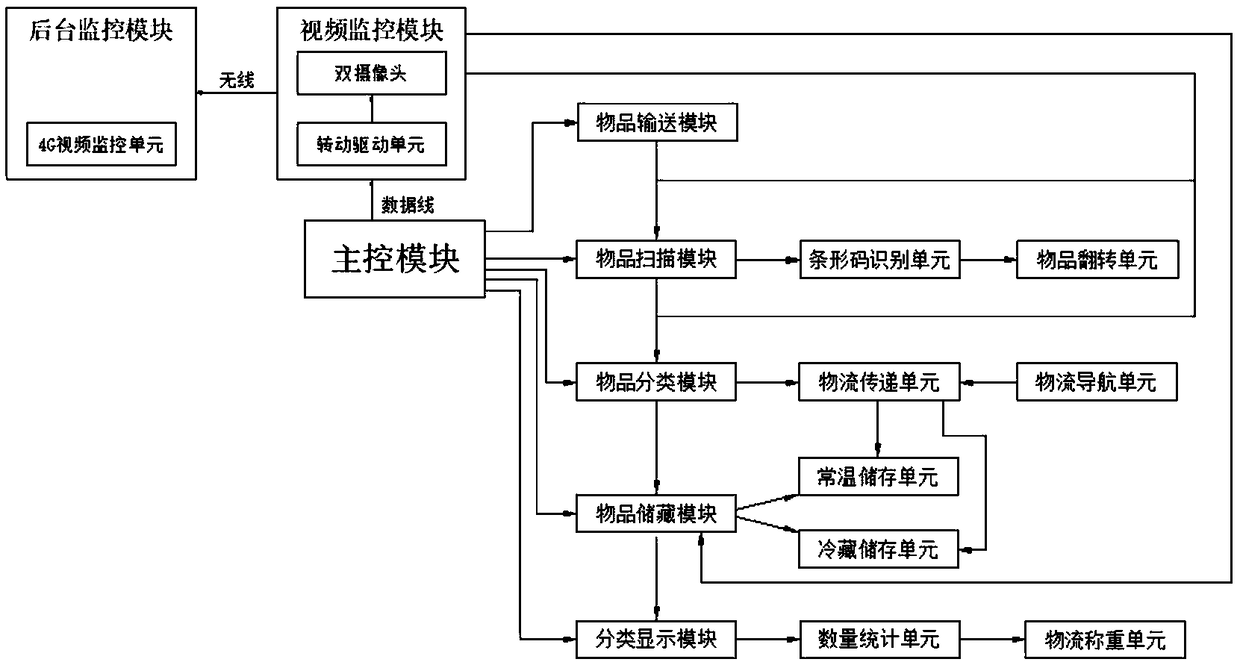

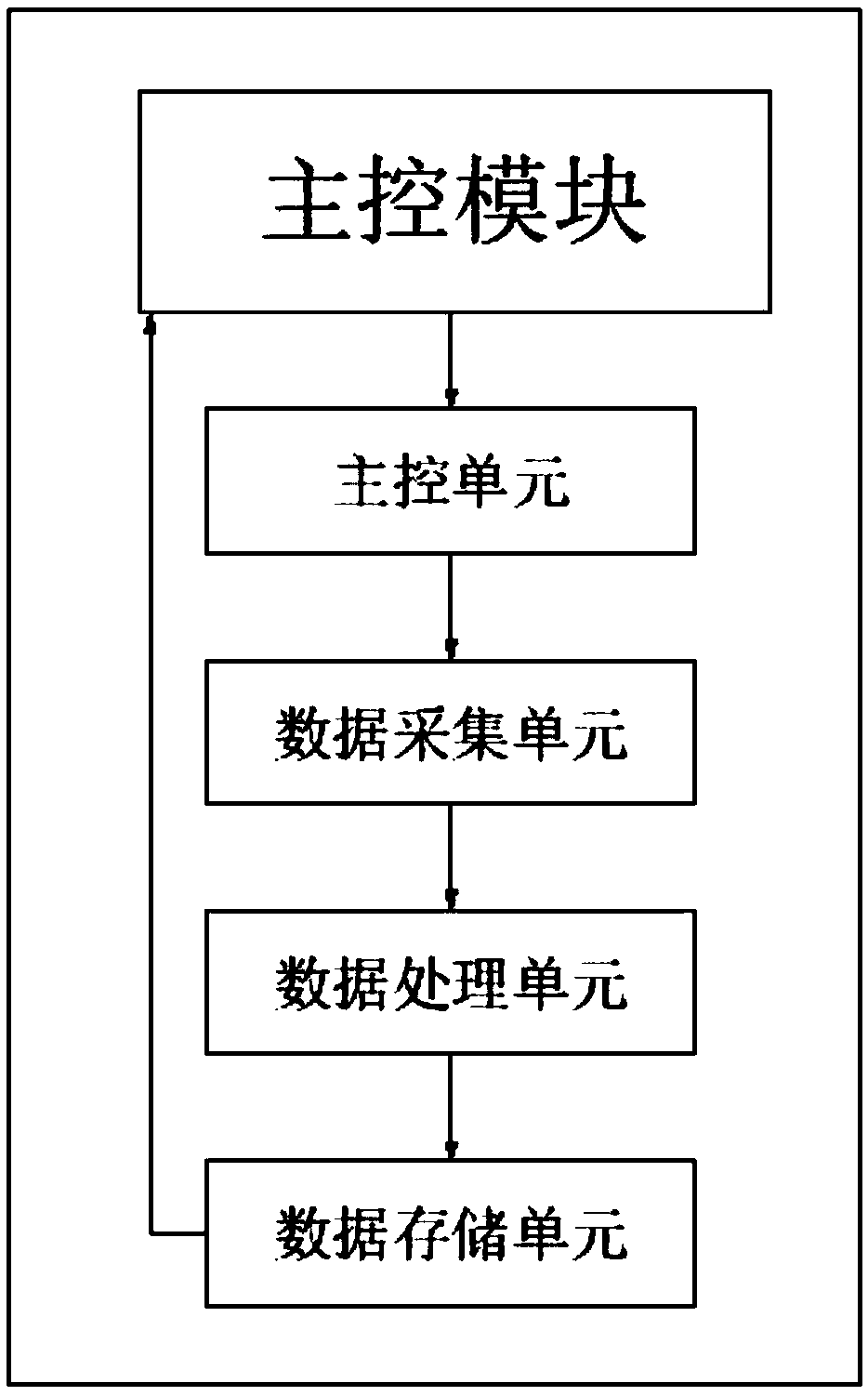

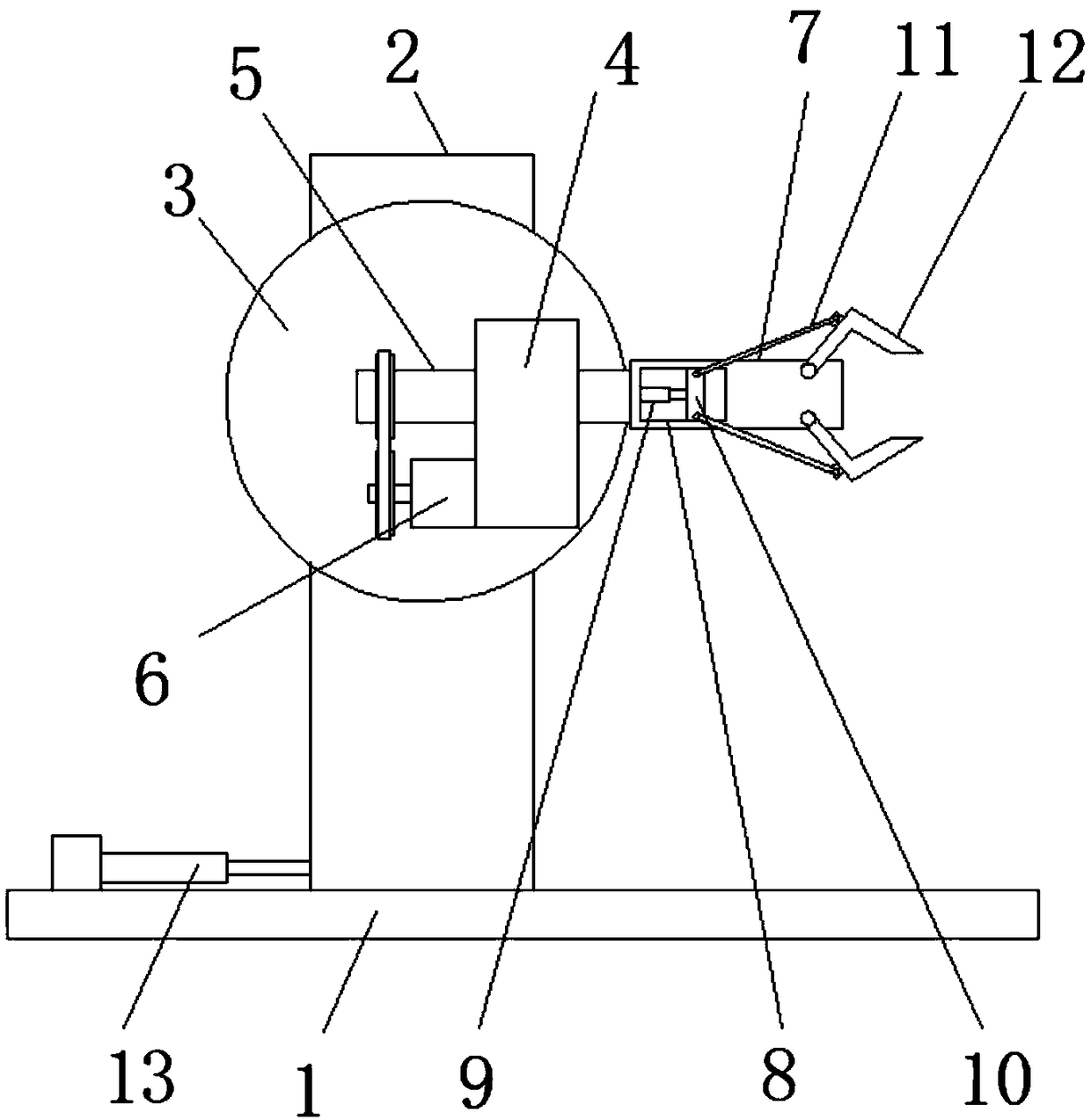

[0024] Reference Figure 1-3 , An automatic classification system for logistics supply chain items, including terminal acquisition module, video monitoring module, background monitoring module, fuel consumption measurement module, logistics weighing module, and personnel registration module. The terminal acquisition module includes a main control unit, a data acquisition unit, and data Identification unit, data matching unit, data processing unit, data storage unit and GPS positioning unit, wherein the output end of the main control unit is respectively connected to the data collection unit, data identification unit, data matching unit, data processing unit and GPS positioning unit, and The output end of the data acquisition unit is connected to the data recognition unit, the data matching unit and the data processing unit in turn, the main control unit is bidirectionally connected to the data storage unit, and the input end of the data storage unit is connected to the fuel cons...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com