Intelligent transfer robot applicable to different volumes of products

A technology of intelligent handling and robots, which is applied in the field of intelligent robots, can solve the problems of increasing labor intensity, reducing transfer efficiency, and the large size of the trolley taking up space, so as to avoid bump damage, increase labor intensity, and reduce handling efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

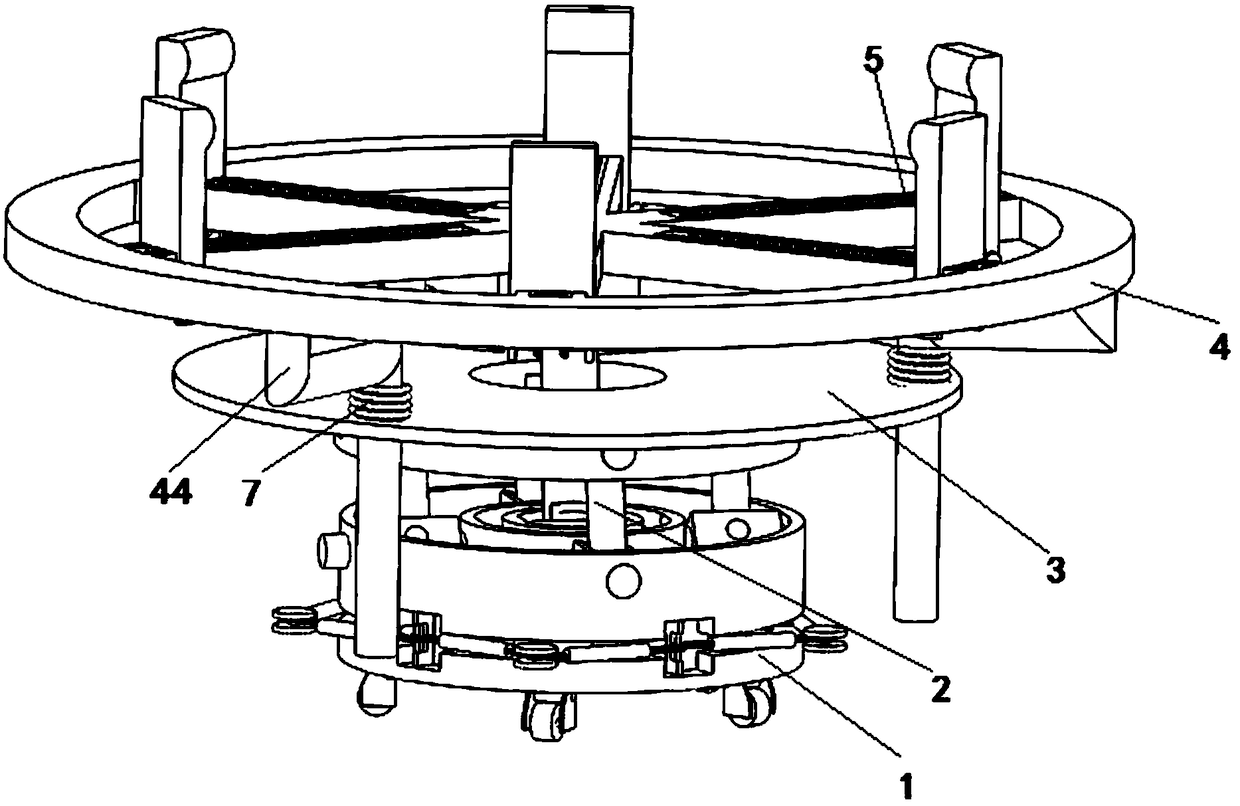

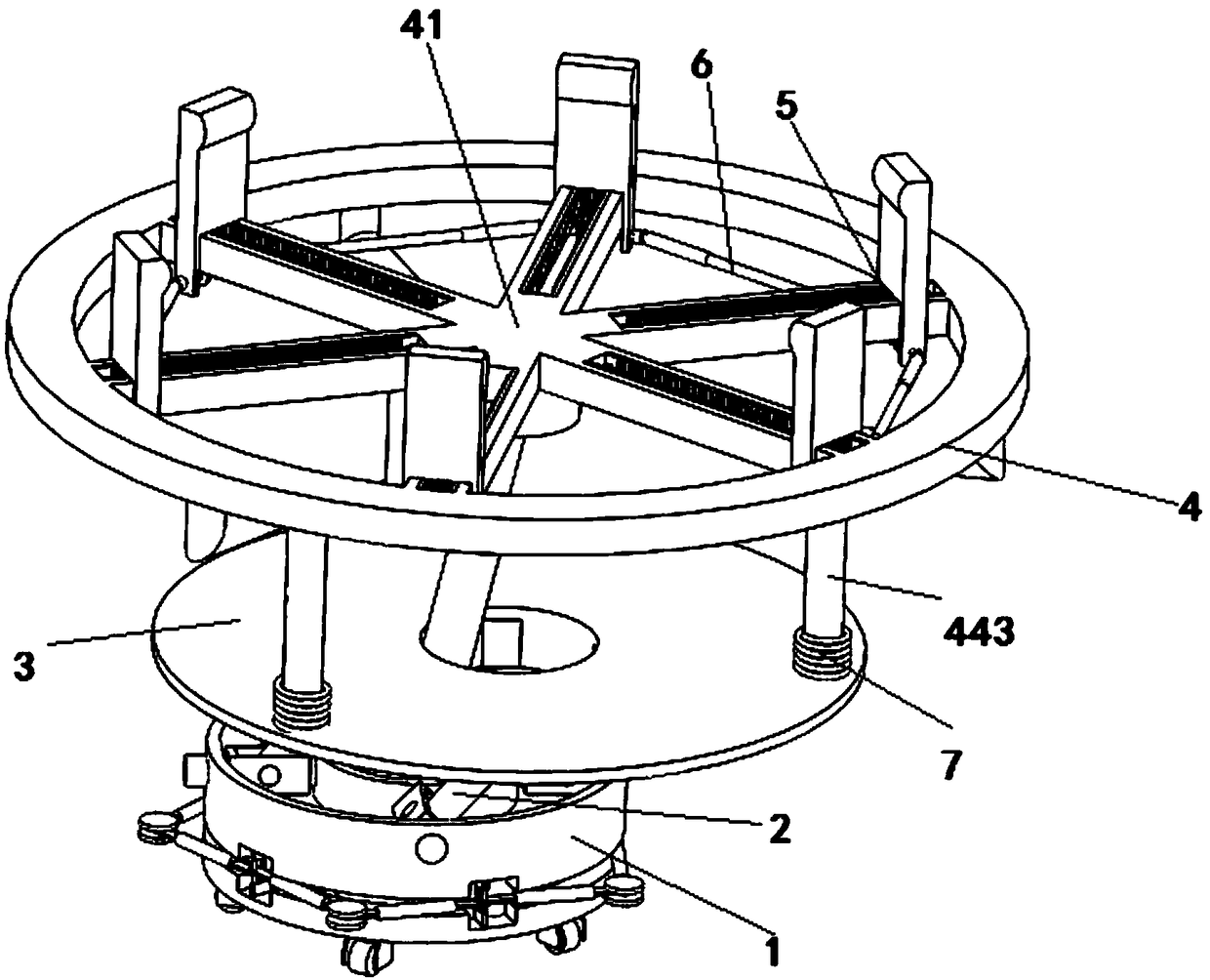

[0043] An intelligent handling robot suitable for products of different sizes, such as figure 1 with figure 2 As shown, it includes the anti-collision walking base 1 and the azimuth adjustment mechanism 2 hingedly fixed on the top side of the anti-collision walking base 1. At the same time, the middle part of the top of the anti-collision walking base 1 is hinged and fixed with a lifting cylinder 3, and the power output end of the lifting cylinder 3 A bearing seat 4 is hingedly fixed, and several clamping and fixing mechanisms 5 are installed and fixed at equal angles on the bearing seat 4;

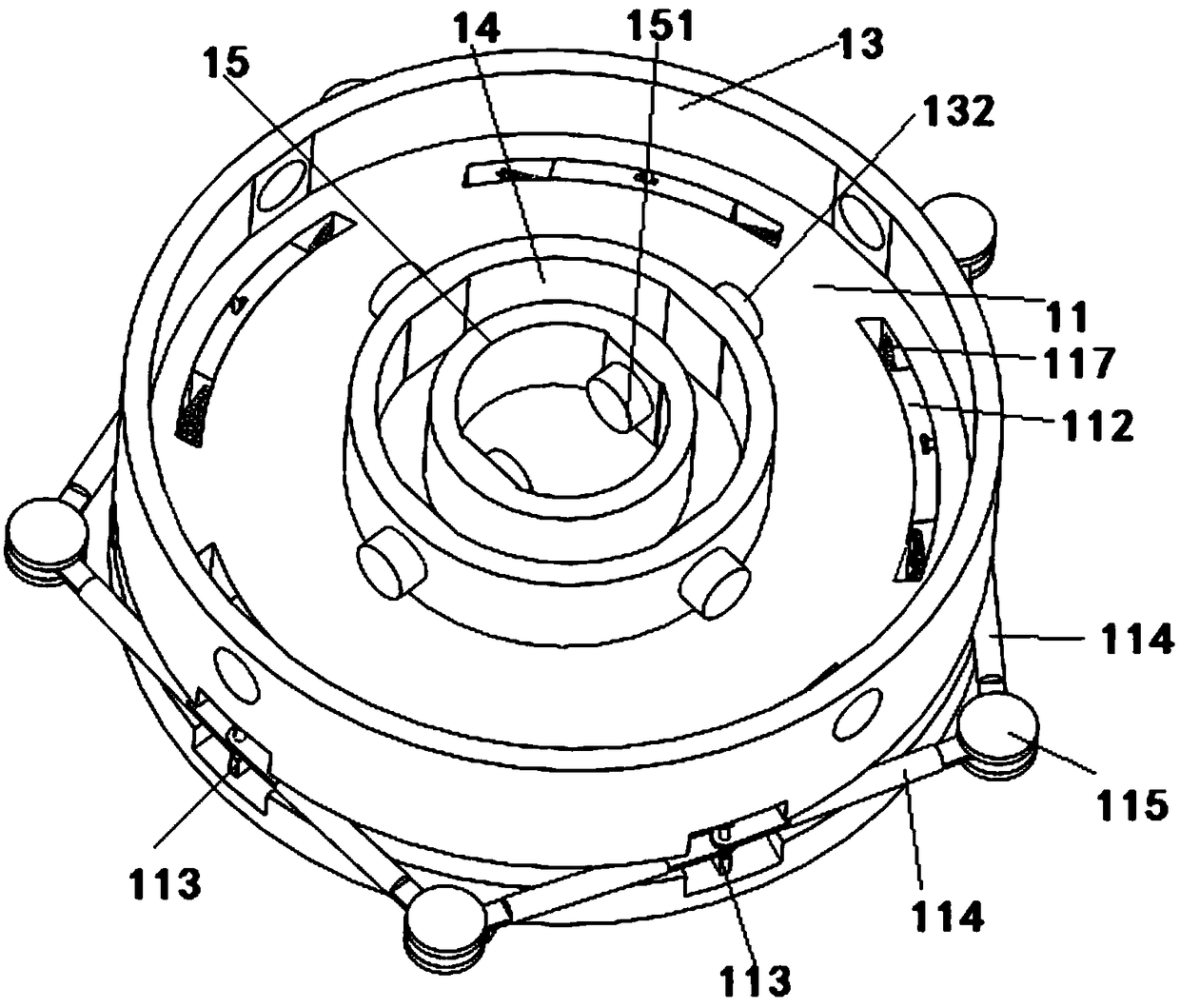

[0044] Such as image 3 , Figure 4 , Figure 5 , Image 6 with Figure 7 As shown, the anti-collision walking base 1 includes a circular support platform 11, a number of universal wheels 12 are uniformly distributed on the bottom surface of the circular support platform 11, and the surface circumference of the circular support platform 11 is equiangularly provided with arc-shaped l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com