Assembling type landscape overflow weir

An overflow weir and assembled technology, which is applied in barrage/weir, water conservancy engineering, sea area engineering, etc., can solve the problems of complicated installation and disassembly of overflow weir, non-adjustable, unsightly, etc., so as to facilitate later maintenance and repair , Easy to install and disassemble, and shorten the time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

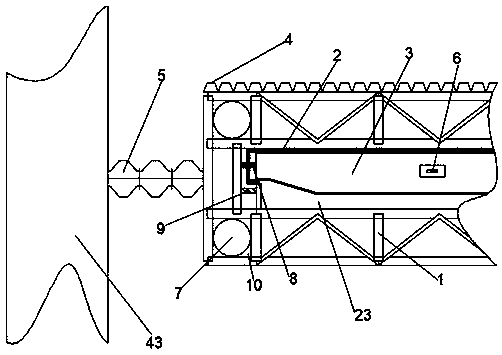

[0030] Embodiment 1: refer to Figure 1-10 ;

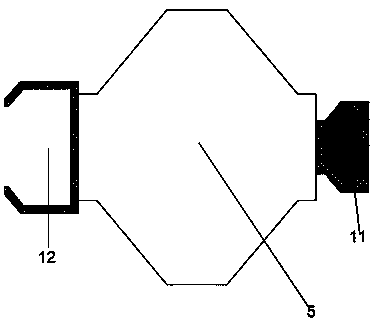

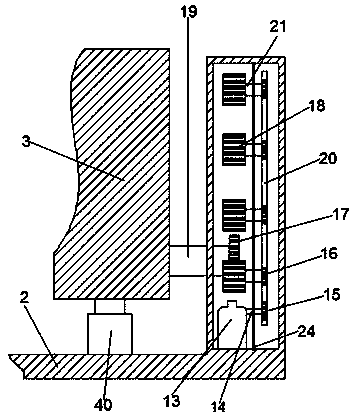

[0031]An assembled landscape overflow weir, comprising a frame box body 1, steel pipe grooves 10 are arranged around the frame box body 1, steel pipe grooves 10 are installed with steel pipes 7, the front of the frame box body 1 is fixedly connected with the first steel sheet pile 4, and the frame box body The middle part of the left and right sides of the body 1 is fixedly connected with one end of the second steel sheet pile 5, and the other end of the steel sheet pile 5 is fixedly connected with the river bed 43. A frame groove 23 is arranged in the middle of the frame box body 1, and a door panel groove 2 is arranged inside the frame groove 23, and the door panel groove 2 A lift door 3 is installed inside, the left and right sides of the bottom of the lift door 3 are fixedly connected with one end of the telescopic support rod 40, the other end of the telescopic support rod 40 is fixedly connected with the left and right sides...

Embodiment 2

[0037] Embodiment 2: based on the basis of embodiment 1, the difference is that;

[0038] In the present invention, when in use, the prefabricated landscape overflow weir is first installed. First, steel pipes 7 are placed at four points in the river, the frame box 1 is suspended by a crane, and the steel pipe grooves 10 around the frame box 1 are Align the steel pipe 7, and connect the steel pipe 7 into the steel pipe groove 10 through a crane, then seal and fix the frame box 1 with cement, and then first fix a second steel sheet pile 5 on the left and right sides of the frame box 1 , the left and right sides of the second steel sheet pile 5 are welded with T-shaped connecting grooves 12 and T-shaped connecting columns 11, and then the second steel sheet pile 5 is spliced by the crane until the second steel sheet pile 5 is connected with the river bed 43, and the spliced The second steel sheet pile 5 forms a water-blocking board, which is poured with cement to form a water-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com