High-speed centrifugal pump with self-circulation system for conveying medium

A self-circulating system and high-speed centrifugal technology, which is applied to the components, pumps, and pump elements of the pumping device for elastic fluids, can solve the complex and bulky structure of the pump body, the difficulty in achieving cooling and flushing of mechanical seals, and the inability to meet multiple tasks. Condition operation and other problems, to achieve the effect of compact structure and light volume of the pump body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

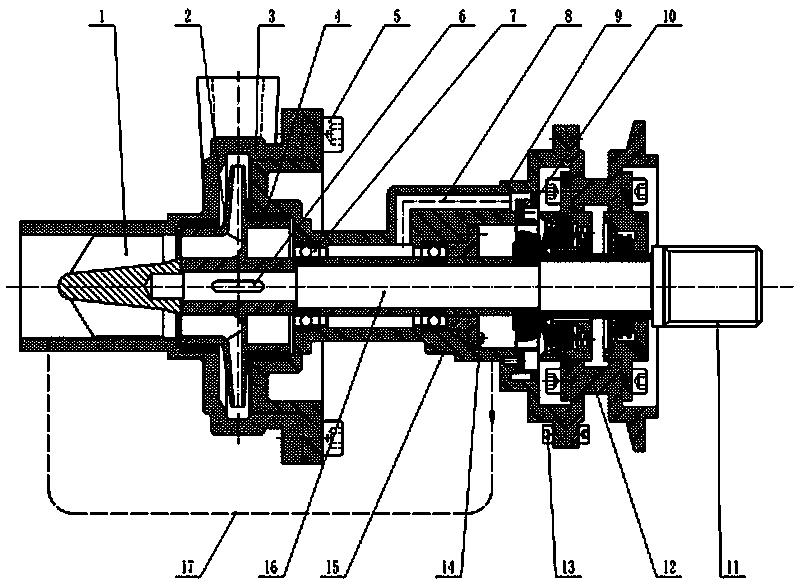

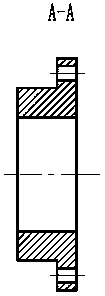

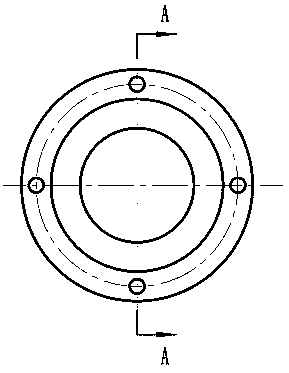

[0007] Such as Figure 1 to Figure 6 , the present invention is a high-speed centrifugal pump with a conveying medium self-circulation system, including an inducer 1, a centrifugal impeller 2, a pump casing 3, a rear mouth ring 4, a cylindrical head hexagon socket bolt 5, an ordinary flat key 6, a pair of bearings 7, Oil inlet pipe 8, bearing chamber 9, injection ring 10, spline 11, mechanical seal assembly 12, cylinder head hexagon socket bolt 13, cylinder head hexagon socket bolt 14, throttle ring 15, shaft 16, oil return pipe 17, inducer 1 The shaft end thread is connected to the shaft 16, and the centrifugal impeller 2 is connected to the shaft 16 through a common flat key 6 to form a rotor part; the pump casing 3 is connected to the bearing chamber 9 through a cylindrical head hexagon socket bolt 5; the mechanical seal assembly 12 is passed through the cylindrical head The hex bolt 13 is connected with the bearing chamber 9; it is composed of the pump casing 3, the rear p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com