One-way valve capable of buffering fluid shocks

A one-way valve and buffer fluid technology, applied in the valve's device for absorbing fluid energy, functional valve type, valve details, etc., can solve the problems of increasing the opening pressure of the one-way valve, complex structure, heavy weight, etc. The effect of disassembly, simple principle and mature process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

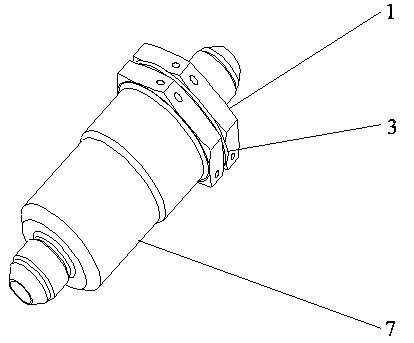

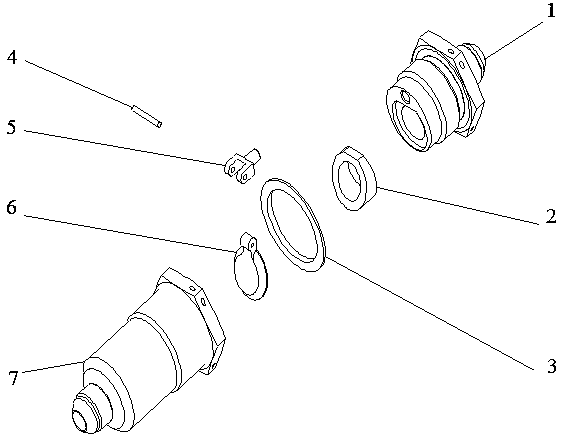

[0029] A one-way valve 19 that can buffer fluid impact includes a valve seat 1 and an outer shell 7, the buffer seat mounting groove 13 inside the valve seat 1 is equipped with a buffer seat 2, and the connecting shaft hole 12 inside the valve seat 1 A connecting shaft 5 is installed at the place, and one end of the connecting shaft 5 is connected with the valve plate 6 through a pin 4, and a sealing ring 3 is sleeved in the sealing ring groove 10 on the valve seat 1, and the valve seat 1 and the outer shell 7 are connected to each other. connect. One end of the buffer seat 2 is embedded in the buffer seat mounting groove 13 of the valve seat 1, and the connection between the buffer seat 2 and the valve seat 1 is realized by vulcanization. Through the pin 4, the two connecting holes 16 of the connecting shaft 5 are connected to the pin holes 18 of the connecting head 17 of the valve plate 6, and then the connecting shaft 15 of the connecting shaft 5 and the connecting shaft ho...

Embodiment 2

[0031] A one-way valve 19 that can buffer fluid impact includes a valve seat 1 and an outer shell 7, the buffer seat mounting groove 13 inside the valve seat 1 is equipped with a buffer seat 2, and the connecting shaft hole 12 inside the valve seat 1 A connecting shaft 5 is installed at the place, and one end of the connecting shaft 5 is connected with the valve plate 6 through a pin 4, and a sealing ring 3 is sleeved in the sealing ring groove 10 on the valve seat 1, and the valve seat 1 and the outer shell 7 are connected to each other. connect.

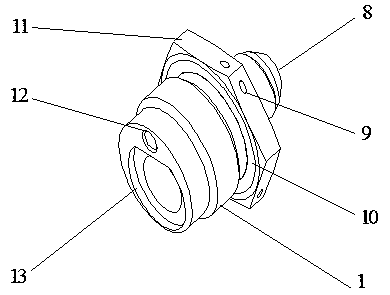

[0032] The outer end of the valve seat 1 is provided with a first hexagonal wrench surface 11 and a first nozzle 8, and the two ends of the outer shell 7 are respectively provided with a second hexagonal wrench surface 21 and a second nozzle 22. Both the first hexagonal wrench surface 11 and the second hexagonal wrench surface 21 are provided with a plurality of safety holes 9 .

[0033] The buffer seat 2 is a hollow structure, an...

example 1

[0040] Example 1, assuming that the buffer seat 2 is not used in the one-way valve:

[0041] The fuel in the fuel system on the aircraft realizes flow control through the fuel pipeline system. The fuel enters the fuel pipeline 24 from the fuel inlet pipeline 23 through the one-way valve, and then enters the fuel outlet pipeline 25 through the shut-off valve, and is delivered to in the follow-up system. When the aircraft needs to stop the fuel delivery of this section of the control pipeline, the aircraft sends a shut-off valve closing command, the shut-off valve is quickly closed, and the fuel flowing in the fuel line 24 suddenly drops to 0 at the shut-off valve. At this time, the shut-off valve and A pressure is generated on the nearby pipe wall. Since the inner wall of the fuel pipe is smooth, the fuel fluid will continue to flow along the previous flow direction due to inertia, and the pressure will quickly reach the maximum. The increased pressure will exert a reverse driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com