Pressure sensor

A pressure sensor and sensor technology, used in the measurement of fluid pressure, instruments, fluid pressure measurement using piezoelectric devices, etc., can solve the problems of pressure sensor core detection accuracy drop, temperature shock, fatigue load fluctuation shock, etc., to achieve protection Effects of Validity and Reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

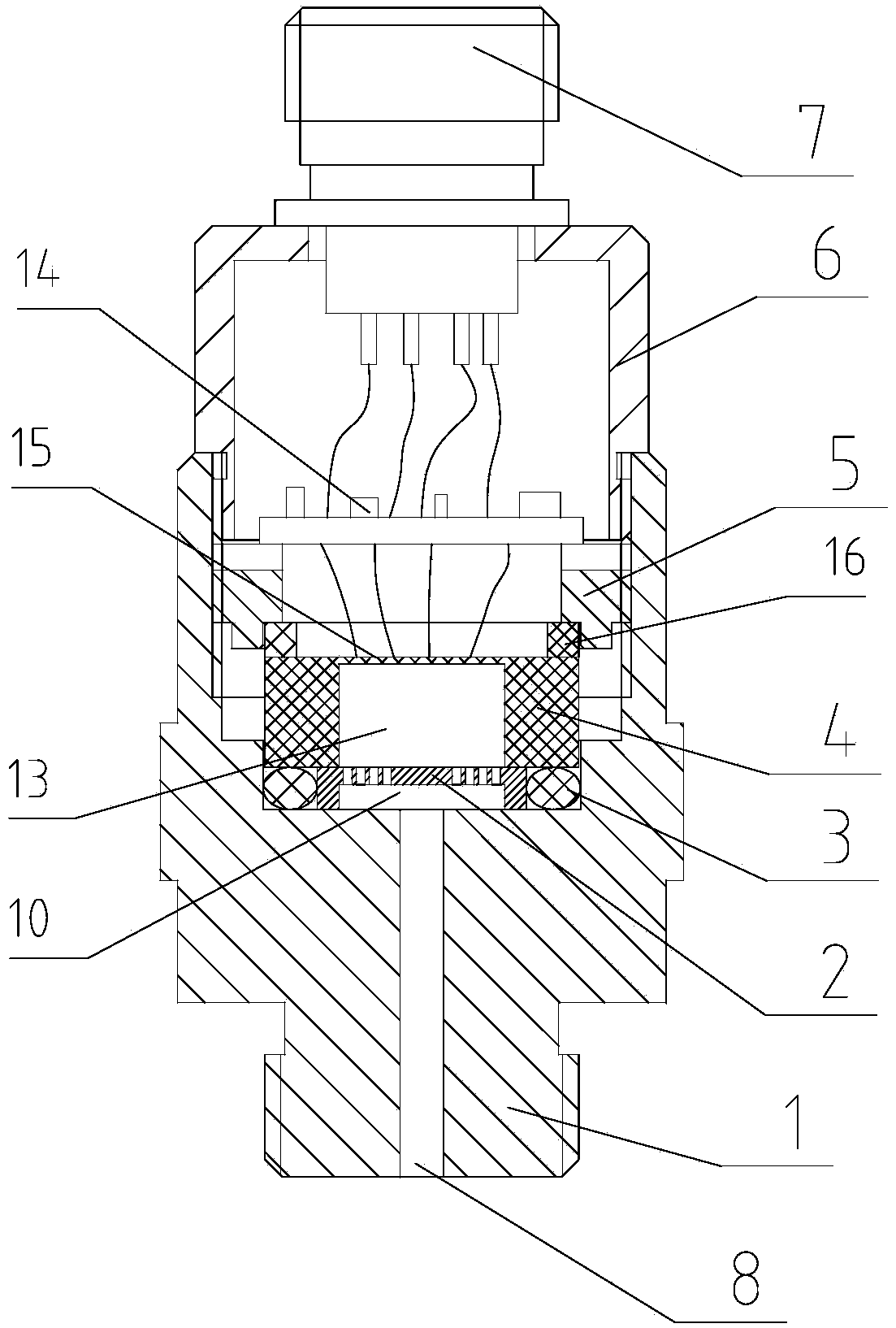

[0040] Such as figure 1 , Figure 7 , Figure 8 , Figure 9 Shown is an embodiment of a pressure sensor of the present invention, a pressure sensor is provided with a lower housing 1 and an upper housing 6, the upper end of the upper housing 6 is provided with an aviation plug 7, and the lower end of the lower housing 1 is provided with The pressure introduction hole 8, the upper end of the lower housing 6 is provided with a sensor pressure core 4, the sensor pressure core 4 is provided with a pressure sensitive bridge 15, the sensor pressure core 4 is also provided with an electronic circuit 14, and the pressure sensitive circuit The bridge 15 is electrically connected with the electronic circuit 14. The bottom of the sensor pressure core 4 is provided with a pressure sensing area 13. The pressure sensing area 13 communicates with the pressure introduction hole 8. The upper end of the sensor pressure core 4 is provided with a compression ring 5. The ring 5 presses the sens...

Embodiment 2

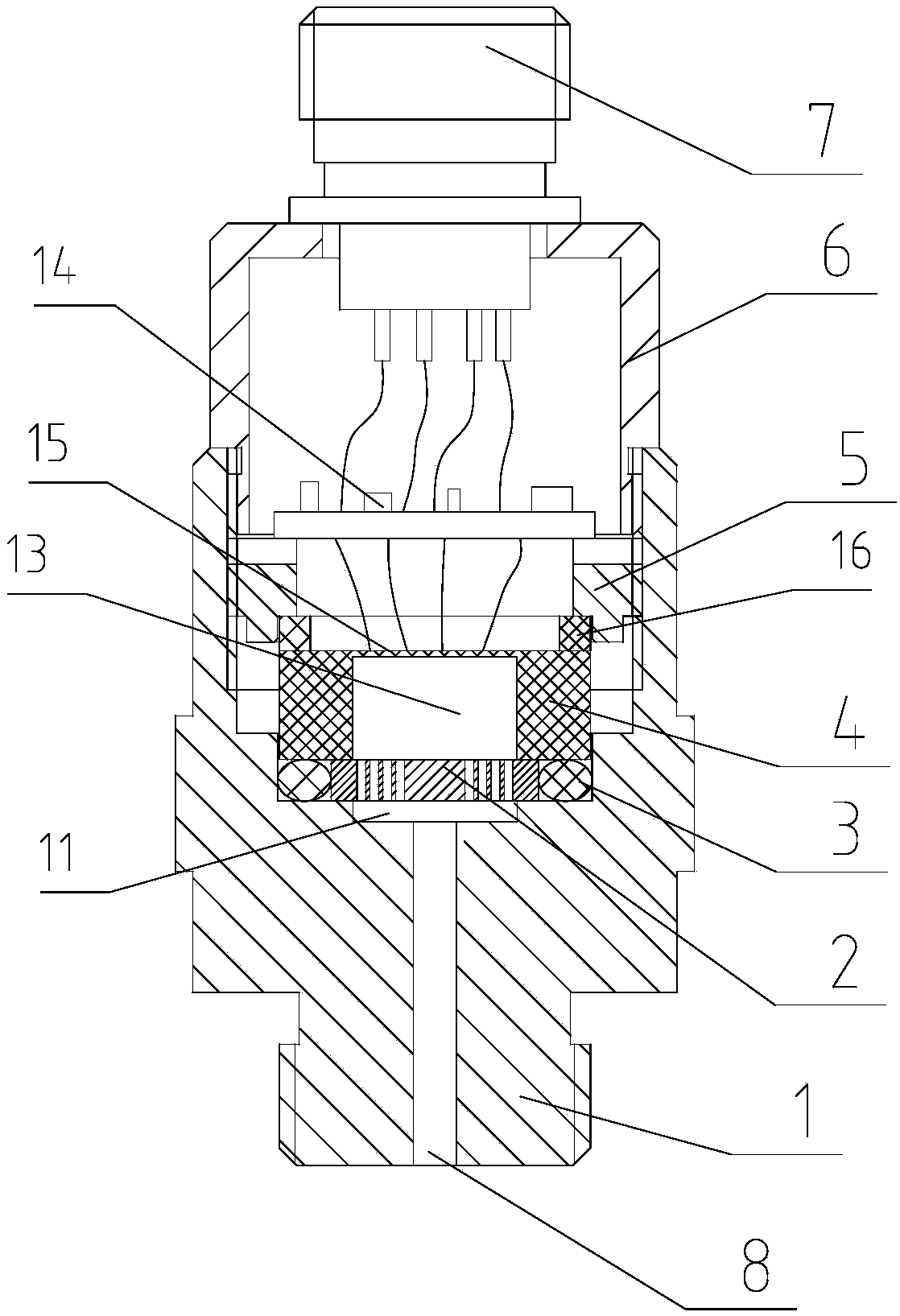

[0047] figure 2 , Figure 6 is another embodiment of a pressure sensor of the present invention, figure 2 is the schematic diagram of the assembly structure of the pressure sensor, Figure 6 is a structural schematic diagram of the pressure buffer ring 2. The difference from Example 1 is that the pressure buffer ring 2 is in the shape of a disc with a certain thickness, and the pressure buffer ring 2 in the shape of a disc is provided with a pressure diversion buffer orifice 9, and the pressure The plane of the buffer ring 2 is the pressure refraction buffer surface 18, and the side of the pressure introduction hole 8 close to the pressure buffer ring 2 is provided with a pressure diversion buffer zone 11. When the pressure oil enters through the pressure introduction hole 8, it first passes through the pressure diversion buffer Zone 11 is buffered, and the pressure release is also realized. At the same time, the pressure oil will also hit the pressure refraction buffer su...

Embodiment 3

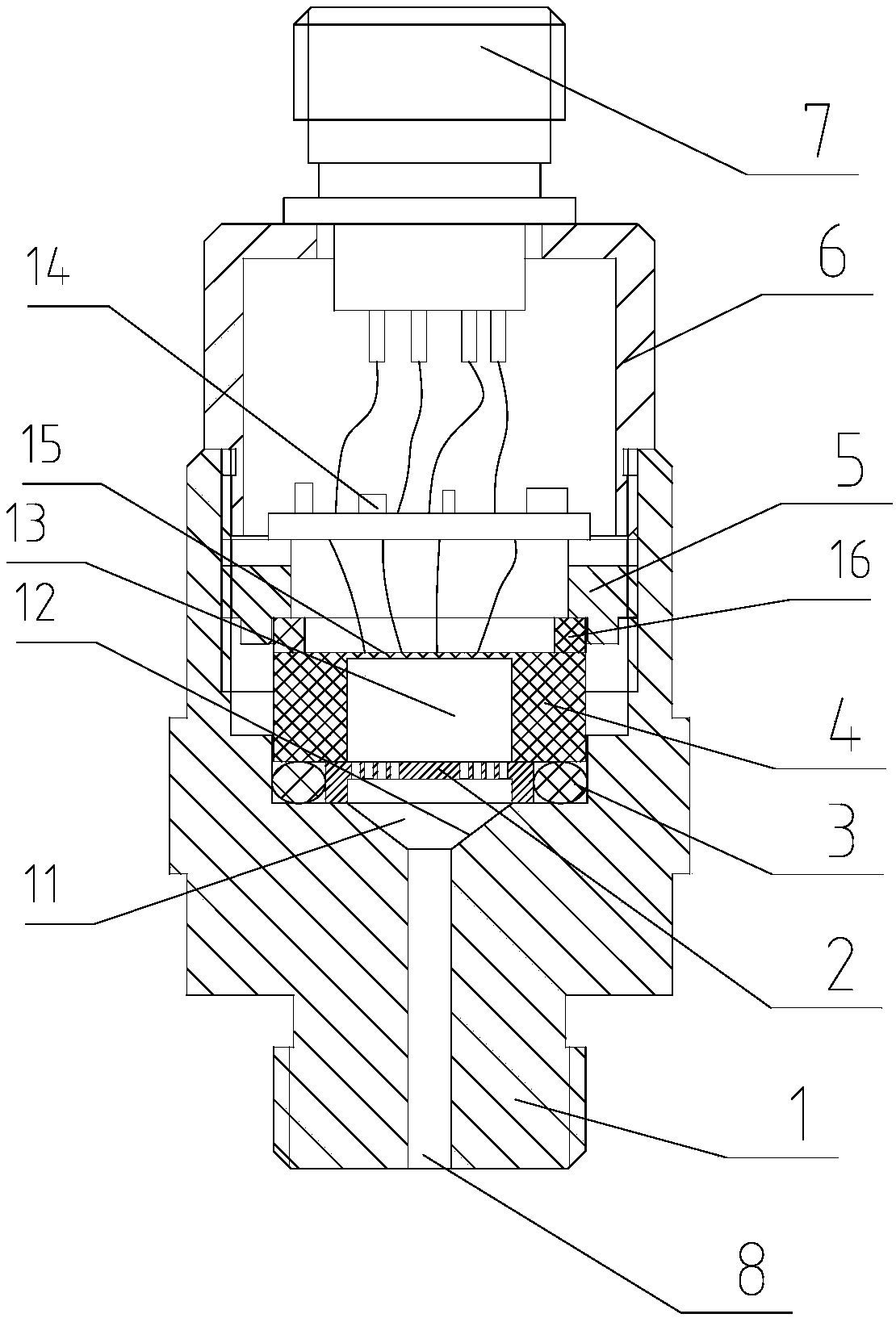

[0050] image 3 It is another embodiment of a pressure sensor of the present invention. It can be seen that the pressure guiding hole 8 is provided with a pressure diversion buffer zone 11 on the side close to the pressure buffer ring 2, and the pressure diversion buffer zone 11 is connected to the pressure buffer ring 2. The pressure buffer release cavity 10 on the top forms a pressure buffer release cavity with a larger space. In this embodiment, the pressure diversion buffer zone 11 provided on the side of the pressure introduction hole 8 close to the pressure buffer ring 2 is in the shape of a conical cavity. One end of the large circle of the conical cavity is connected to the pressure buffer release cavity 10 connected to the inner side of the support portion 17 of the pressure buffer ring 2, and the inner surface of the inner conical cavity of the pressure diversion buffer zone 11 is a pressure diversion release slope 12, and the pressure guide The pressure diversion bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com