Tower type hot air dryer

A hot air dryer and tower technology, which is used in the field of air drying equipment in the industrial, agricultural and medical fields, can solve the problems of numerous materials and supporting products, increased construction costs, cumbersome integrated installation, etc., to achieve flexible drying range, improve work efficiency, Good energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

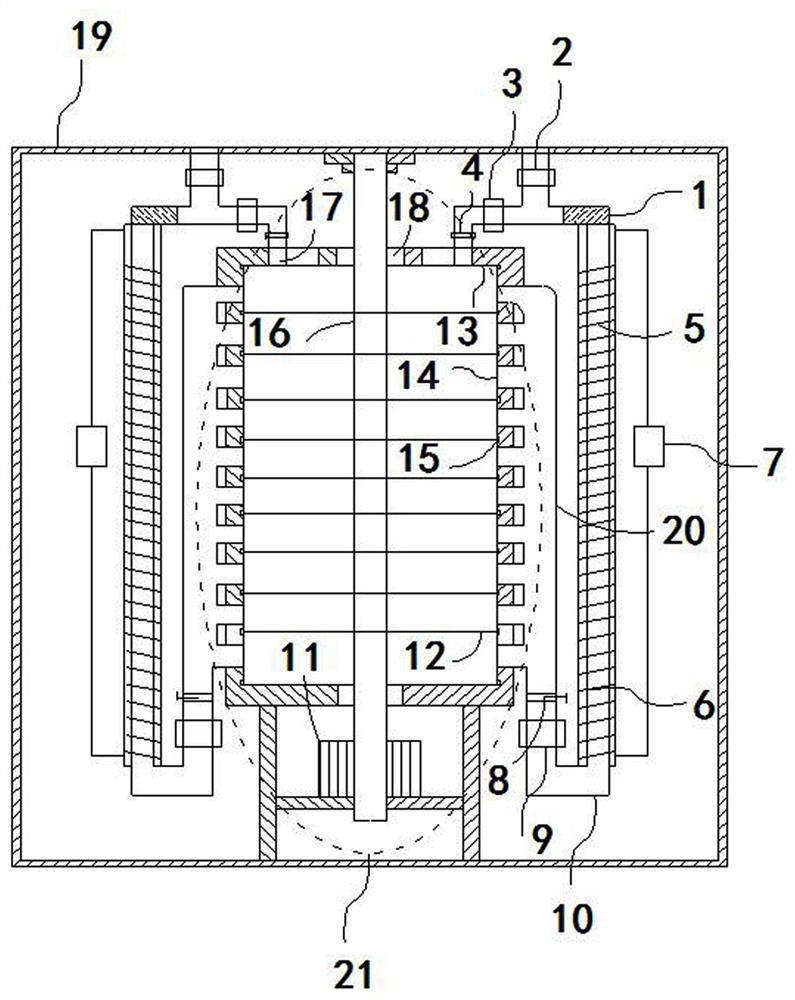

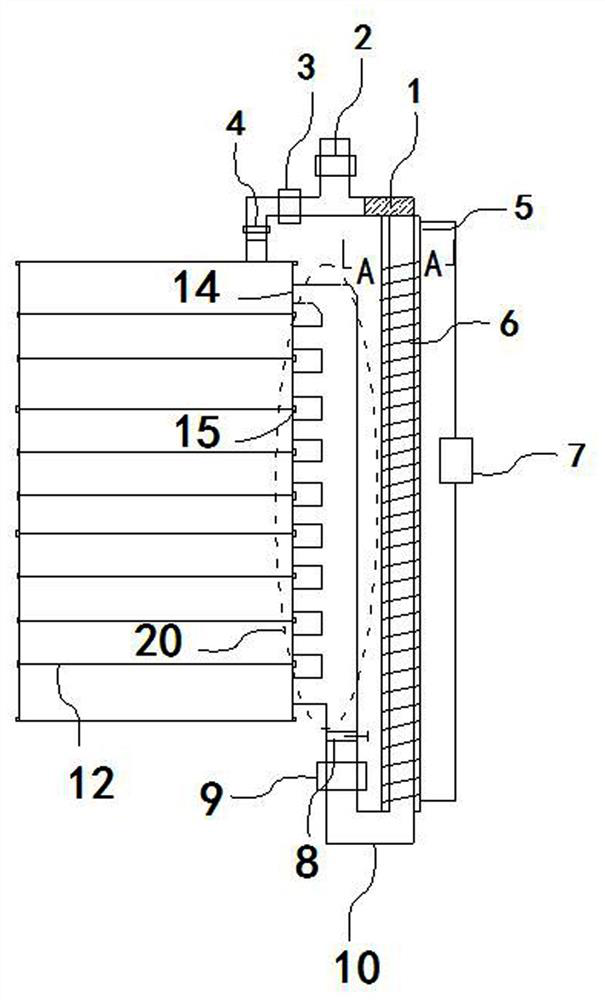

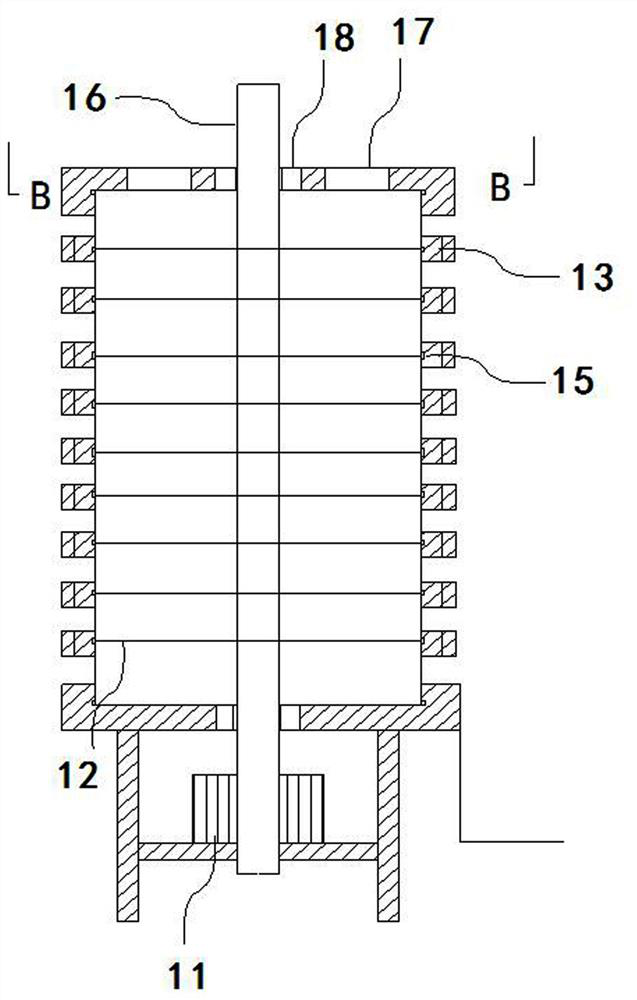

[0031] As shown in the figure, the tower type hot air dryer includes an air drying chamber 21 and a hot air circulation part;

[0032] Described air-drying chamber 21 comprises insulation wall 13, mesh tray 12, motor 11 and the main shaft 16 of longitudinal linkage with described motor 11; Described mesh tray 12 is placed in insulation wall 13; Described motor 11 It is fixedly arranged at the bottom of the air-drying chamber 21; the mesh tray 12 is fixedly connected with the main shaft 16 laterally;

[0033] The hot air circulation part includes a cooling fan 3, an induced draft fan 2, an electromagnetic induction heating module and a heat medium distributor 20;

[0034] The refrigerant outlet of the drying chamber 21 communicates with the refrigerant inlet of the electromagnetic induction heating module through the cooling fan 3 and the induced draft fan 2; the heat medium outlet of the electromagnetic induction heating module communicates with the heat medium distributor thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com