An Optimal Method for Hydrometallurgical Leaching Process with Interval Uncertainty

An uncertain, hydrometallurgical technology, applied in the field of hydrometallurgy, can solve the problem that the mechanism model or data model cannot meet the production requirements of the hydrometallurgical leaching process, and achieve the effect of fast calculation speed and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

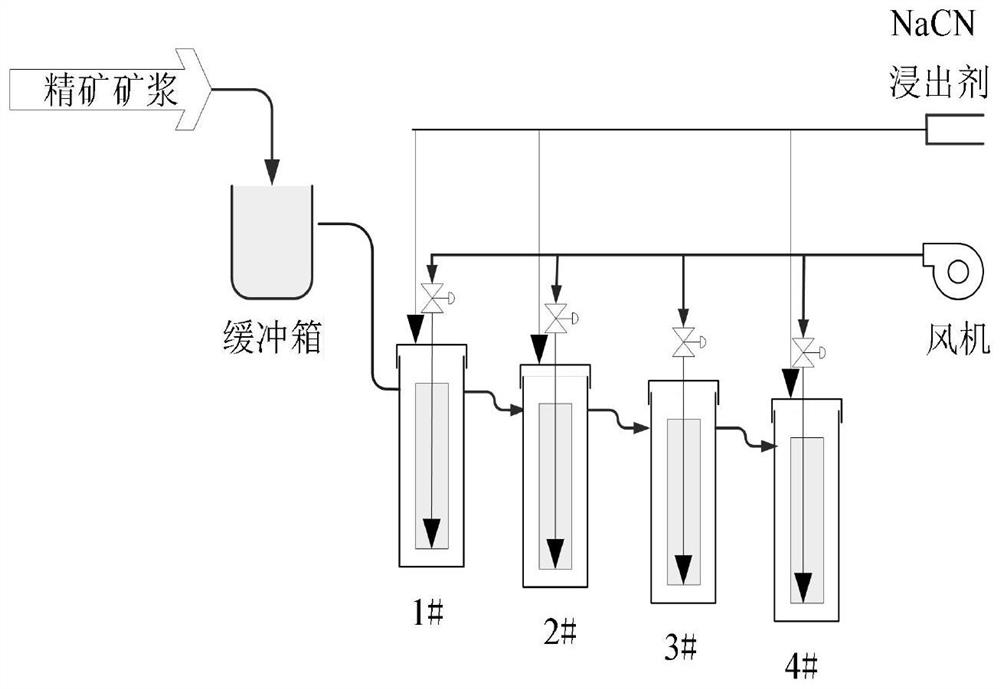

[0103] The single-stage leaching process of hydrometallurgy such as figure 1 As shown, the leaching process consists of a primary leaching process and a secondary leaching process, both of which consist of four pneumatic continuous stirred tank reactors (CSTRs) connected in series. The pulp after sizing is pumped into the first leaching tank, and each tank is connected by overflow. In the first, second and fourth tanks, sodium cyanide, insoluble gold in the solid phase, and insoluble in the pulp are added. Dissolved oxygen reacts to form gold cyanide complex ions that are soluble in water. The ore pulp after the primary leaching is subjected to a vertical filter press for solid-liquid separation to obtain a filter cake and a filtrate. The uncertain filter cake amount and ore gold grade are put into the sizing tank, and the ore pulp after sizing enters the four leaching tanks in the secondary leaching process in turn, and the same chemical reaction occurs.

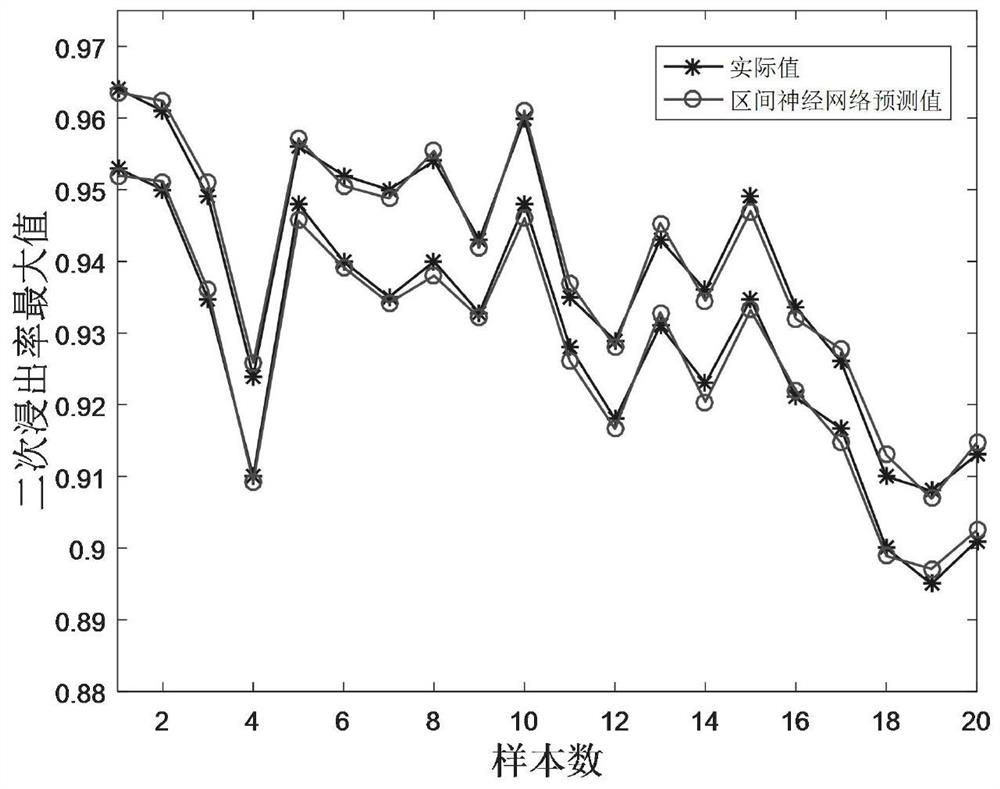

[0104] The specif...

Embodiment 2

[0223] Step 1: Aiming at the uncertainty of two slurry concentrations in the hydrometallurgical leaching process, the present invention proposes to use interval numbers to describe the slurry concentration, and the first leaching slurry concentration C w1 and the second leaching pulp concentration C w2 It is divided into five states: NB (negative large), NS (negative medium), ZE (zero), PS (positive medium), and PB (positive large). The pulp concentration C w1 and C w2 As the input condition of the mechanism model, the leaching rate of each stage and the total leaching rate are finally obtained. Then, the interval analysis theory was combined with the leaching process mechanism analysis to establish an optimization model of the gold cyanide leaching process based on interval uncertainty.

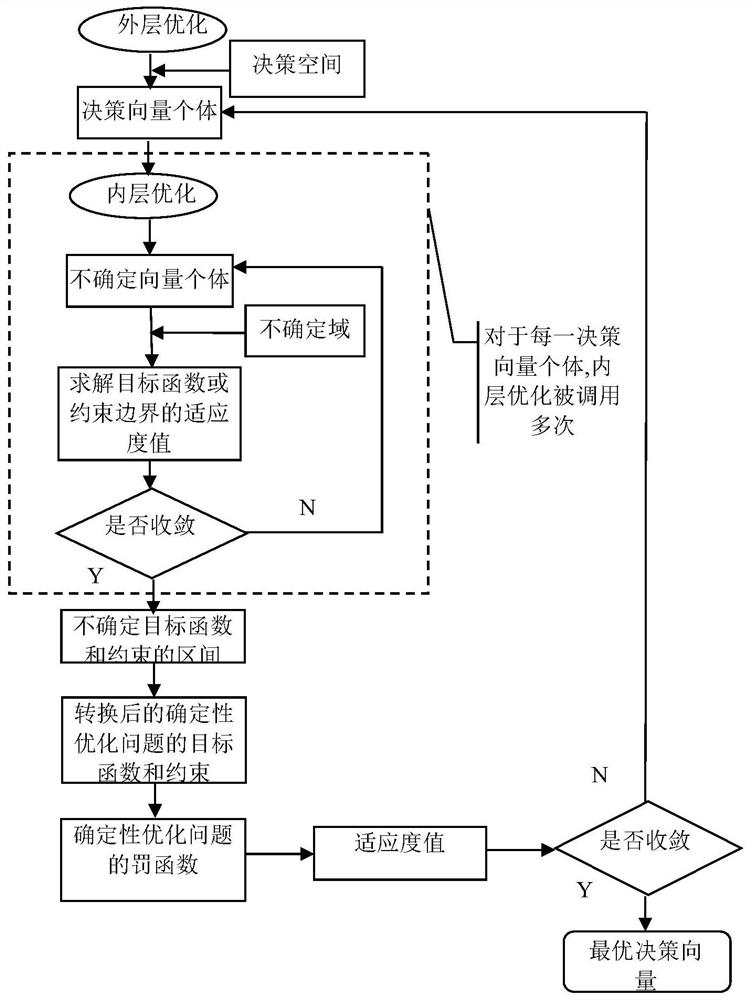

[0224] Step 2: The present invention proposes an improved DE-SQP hybrid optimization algorithm by combining the respective advantages of SQP and DE, which enhances its ability to solve co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com