Direct liquid-cooled distributed gain laser based on polarized double-pass side pump

A polarization beam splitter and laser technology, applied in the direction of lasers, laser components, laser components, etc., can solve the problems of low output efficiency of lasers, low heat distribution of laser crystals, affecting laser overlapping efficiency, etc., and achieve thermally induced tilted images Poor effective, reduce the effect of defocus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

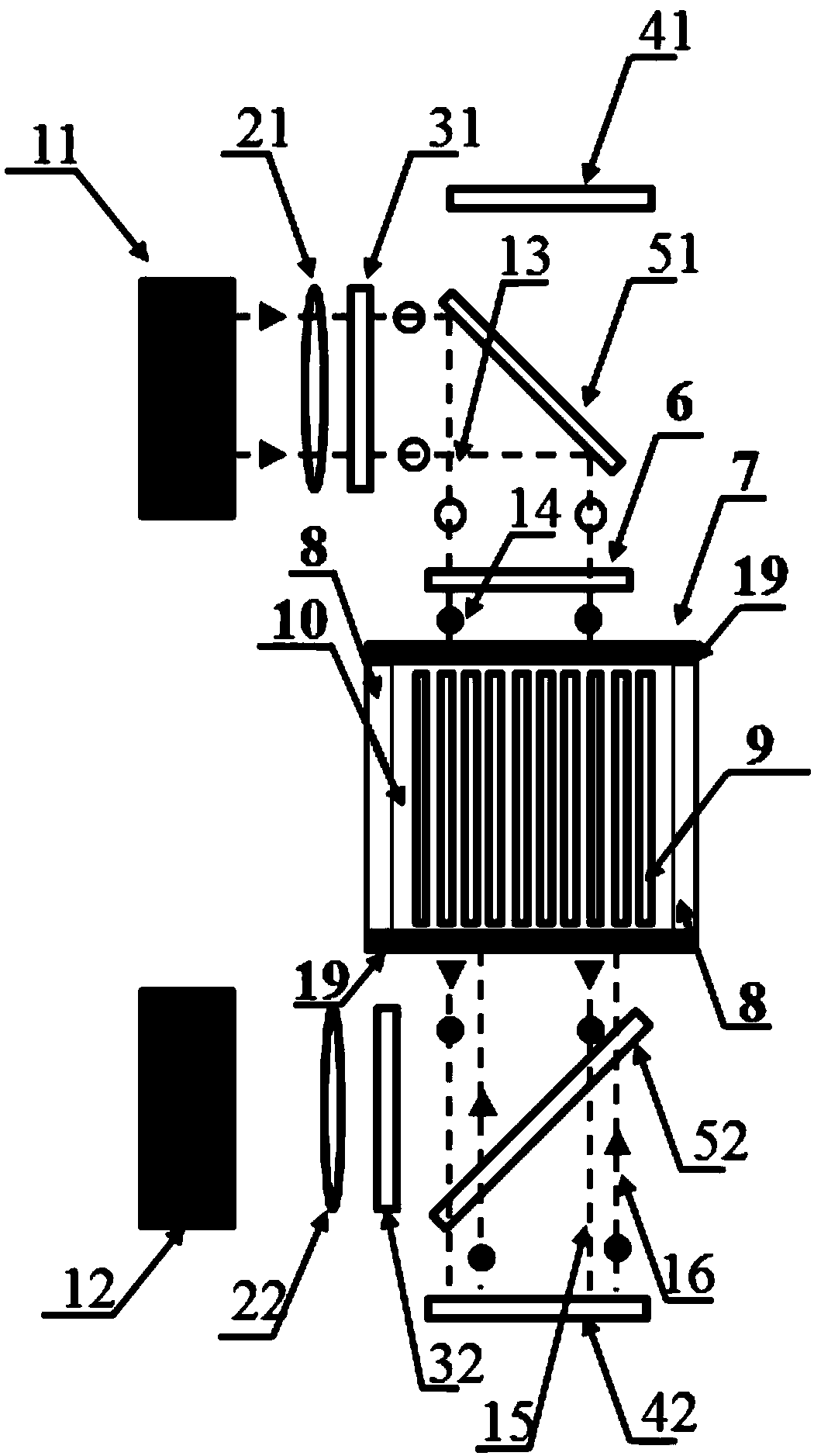

[0027] Such as figure 1 As shown, it is a gain unit for a direct liquid-cooled array distributed gain laser based on multi-pass side pumping, the gain unit includes the first direct liquid-cooled array distributed gain module (7), gain module one A first pumping module and a 1 / 2 wave plate (6) are arranged on one side, and a second pumping module is arranged on the other side.

[0028]In the direction of the optical path, the first pumping module sequentially includes a first laser diode array pumping source (11), a first fast-axis shaping mirror (21), a first slow-axis shaping mirror (31), and a first reflector ( 41), the first polarization beam splitter (51); the second pumping module includes the second laser diode array pumping source (12), the second fast axis shaping mirror (22), the second slow axis shaping mirror ( 32), the second reflection mirror (42), the second polarizing beam splitter (52); the array type distribution gain module (7) of the first direct liquid co...

Embodiment 2

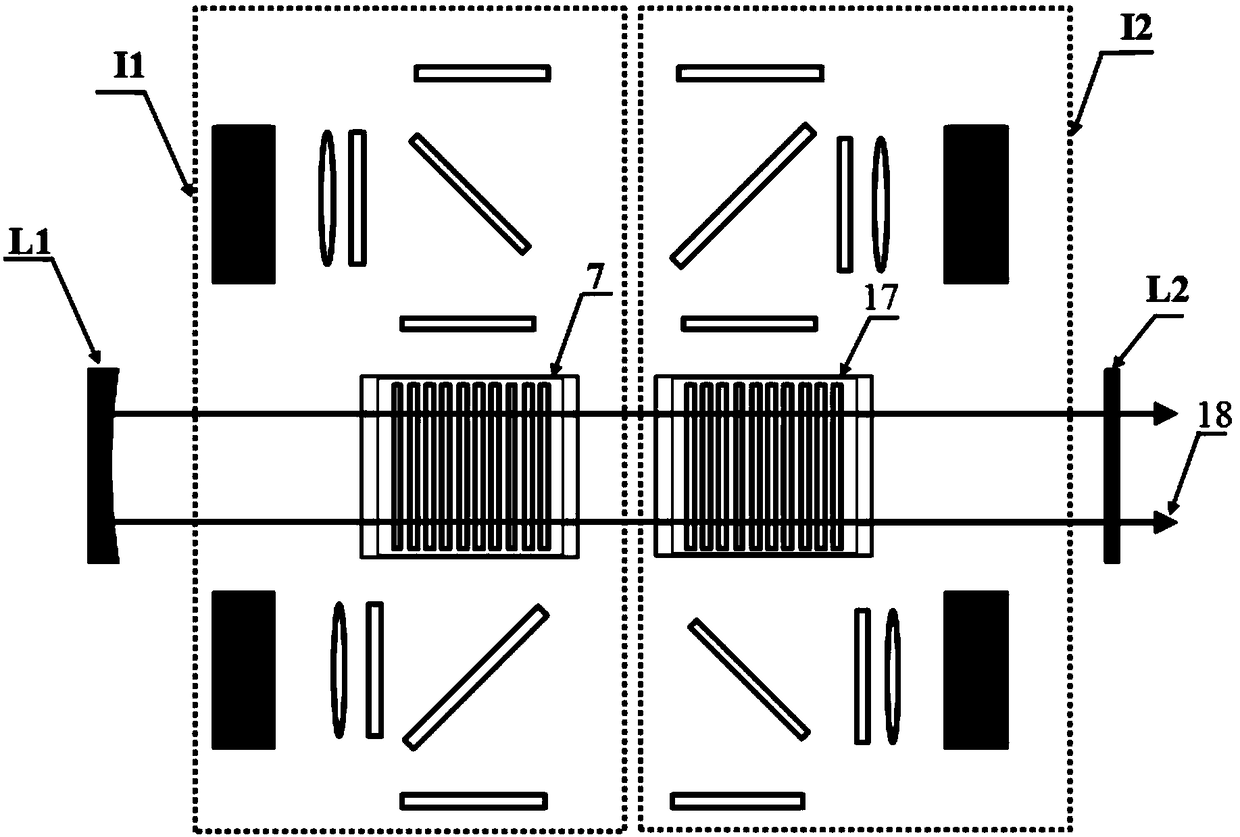

[0035] Such as figure 2 Shown is a direct liquid-cooled array distributed gain laser based on multi-pass side pumping. The laser system is sequentially composed of a concave reflector L1, two gain units (I1 and I2) and a laser output coupling mirror L2, and the gain units (I1 and I2) are the gain units described in any of the foregoing embodiments.

[0036] In this laser system, the pump coupling system, gain module structure and pump optical path system of the two gain units are exactly the same, the difference is that the cooling fluid flow directions of the direct liquid-cooled gain modules in the two gain units are opposite . Such as figure 2 As shown, if two gain units I1 and I2 with the same structure are symmetrically arranged, the liquid flow direction of the second direct liquid-cooled array distributed gain module 17 is the same as the liquid flow direction of the first directly liquid-cooled array distributed gain module 7. The direction is opposite, and the tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com