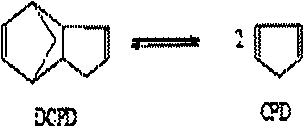

A kind of method for preparing cyclopentadiene by gas phase depolymerization of dicyclopentadiene

A technology of dicyclopentadiene and cyclopentadiene, which is applied in the direction of depolymerization, hydrocarbon production, organic chemistry, etc., can solve problems such as depolymerization cannot be carried out, coking, clogging of reaction tubes, etc., so as to reduce entrainment loss, reduce costs, and save energy Effect of N2

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

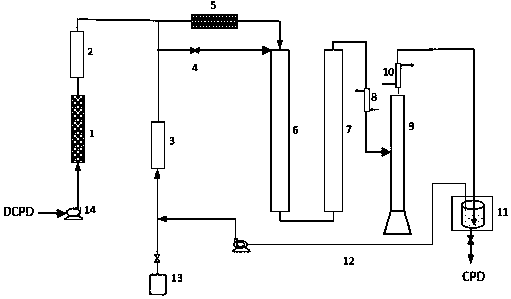

Method used

Image

Examples

example 1

[0073] Using carbon ten with a DCPD content of 80% as a raw material, using the process flow of the present invention, the temperature of the first-stage depolymerizer is controlled at 240°C; the temperature of the second-stage depolymerizer is controlled at 300°C, and the residence time is 7s, n(N 2 ) / n(DCPD)=1:1, a 1200h continuous operation experiment was carried out, and the product analysis results showed that the DCPD depolymerization rate was 99.7%, the CPD yield was 99.0%, and no coke was produced.

example 2

[0075] Using carbon ten with a DCPD content of 80% as a raw material, using the process of the present invention, the temperature control of the first-stage depolymerizer is 270°C; the temperature control of the second-stage depolymerizer is 300°C, and the residence time is 7s, n(N 2 ) / n(DCPD)=1:1, a 1200h continuous operation experiment was carried out, and the product analysis results showed that the DCPD depolymerization rate was 99.9%, the CPD yield was 99.5%, and no coke was produced.

example 3

[0077] Using carbon ten with a DCPD content of 80% as raw material, using the process of the present invention, the temperature control of the first-stage depolymerizer is 240°C; the temperature control of the second-stage depolymerizer is 280°C, and the residence time is 5s, n(N 2 ) / n(DCPD)=1:1, a 1200h continuous operation experiment was carried out, and the product analysis results showed that the DCPD depolymerization rate was 99.1%, the CPD yield was 98.4%, and no coke was produced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com