Using method used for PVC pipe sleeving of circuit control line and capable of realizing good anti-dew effect

A PVC pipe and circuit control technology, applied in the direction of electrical components, etc., can solve problems affecting the service life of electrical control lines and lines, and corrosion of electrical control lines and lines, so as to reduce the risk of corrosion, improve the insulation effect, and improve The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

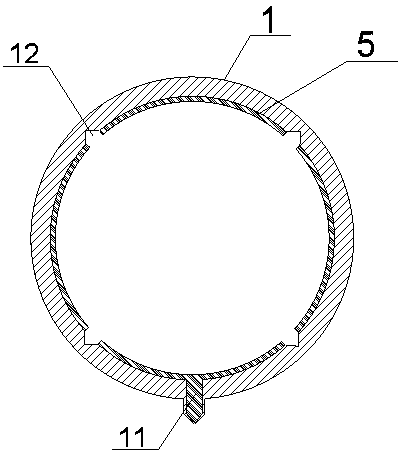

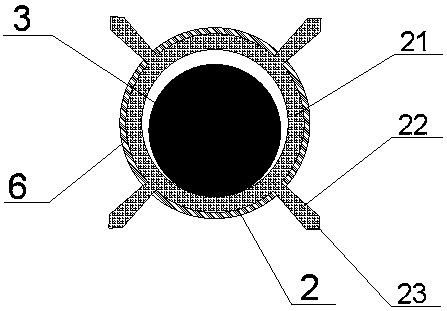

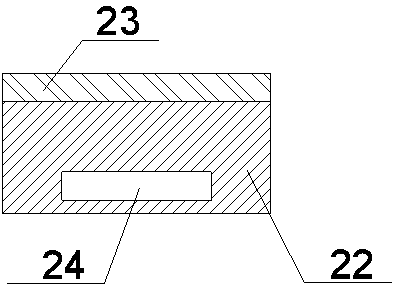

[0036] This embodiment provides a method for using a PVC pipe socketed for circuit control lines with good anti-dew effect. The PVC pipe is used for the installation and layout of electrical control lines and lines in weak current hydropower projects, so that the electrical control lines and lines pass through the PVC pipe. like Figure 1~Figure 3 As shown, the double-layered PVC pipe includes: an outer PVC pipe 1 with a plurality of drainage holes 11 at the bottom; an inner PVC pipe 2 with an electrical control circuit 3 inside, and the inner PVC pipe 2 is connected to the outer Layer PVC pipe 1 is clamped, and a certain drainage space 4 is formed between the inner layer PVC pipe 2 and the outer layer PVC pipe 1; the inner wall of the outer layer PVC pipe 1 is bonded with a first rubber and plastic insulation layer 5, and the The outer wall of the inner layer PVC pipe 2 is bonded with a second rubber and plastic insulation layer 6 .

[0037] In the prior art, the electrical...

Embodiment 2

[0047] This embodiment provides a method for using a PVC pipe socket for circuit control lines with good anti-dew effect, and makes the inner PVC pipe 2 and the outer PVC pipe 1 detachable. Similar to Embodiment 1, the PVC pipe is used for the installation and layout of electrical control lines and lines in weak current hydropower projects, so that the electrical control lines and lines are passed through the PVC pipe. like Figure 1~Figure 3 As shown, the double-layered PVC pipe includes: an outer PVC pipe 1 with a plurality of drainage holes 11 at the bottom; an inner PVC pipe 2 with an electrical control circuit 3 inside, and the inner PVC pipe 2 is connected to the outer Layer PVC pipe 1 is clamped, and a certain drainage space 4 is formed between the inner layer PVC pipe 2 and the outer layer PVC pipe 1; the inner wall of the outer layer PVC pipe 1 is bonded with a first rubber and plastic insulation layer 5, and the The outer wall of the inner layer PVC pipe 2 is bonded w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com