Razor clam digging machine

A car body, articulated technology, applied in fish farming, application, animal husbandry and other directions, can solve the problems of high labor intensity and low productivity, and achieve the effects of low cost of use, reduced labor cost, and avoidance of loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

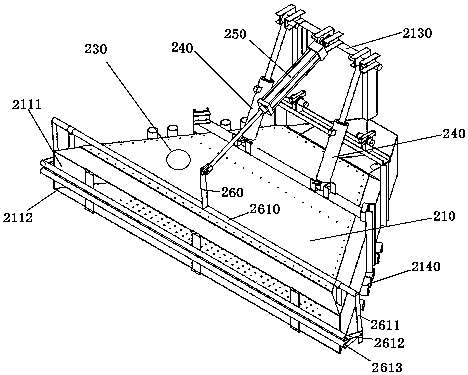

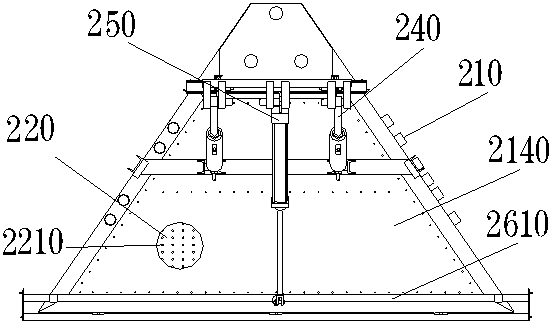

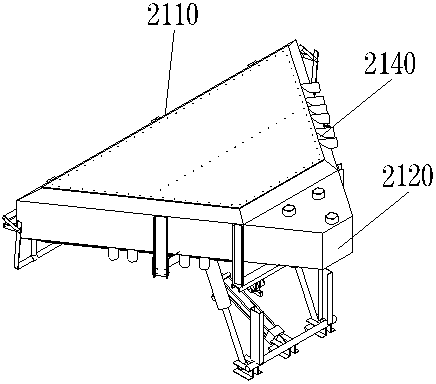

[0016] Such as Figure 1~4 Shown, a kind of clam digging machine comprises car body 10 and is arranged on the collecting device 20 of car body front side.

[0017] The collection device 20 includes an angular collection cabin 210 gradually narrowed from the front end to the rear end, the front end and the rear end of the collection cabin are provided with openings, the front opening is provided with a front baffle 2110, and the rear opening is provided with a There is a rear flashboard 2120, a mud filter plate 220 is provided in the collection cabin, a filter hole 2210 is provided on the mud filter plate 220, a water injection port 230 is provided at the upper end of the collection cabin 210, and a water injection port 230 is provided on the upper surface of the collection cabin. There is a baffle control device for controlling the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com