Intelligent manipulator with multistage air cylinder

An intelligent manipulator and cylinder-type technology, applied in the field of manipulators, can solve the problems of inconvenient operation, inconsistent height, inconvenient loading and unloading, etc., to reduce costs and improve handling efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

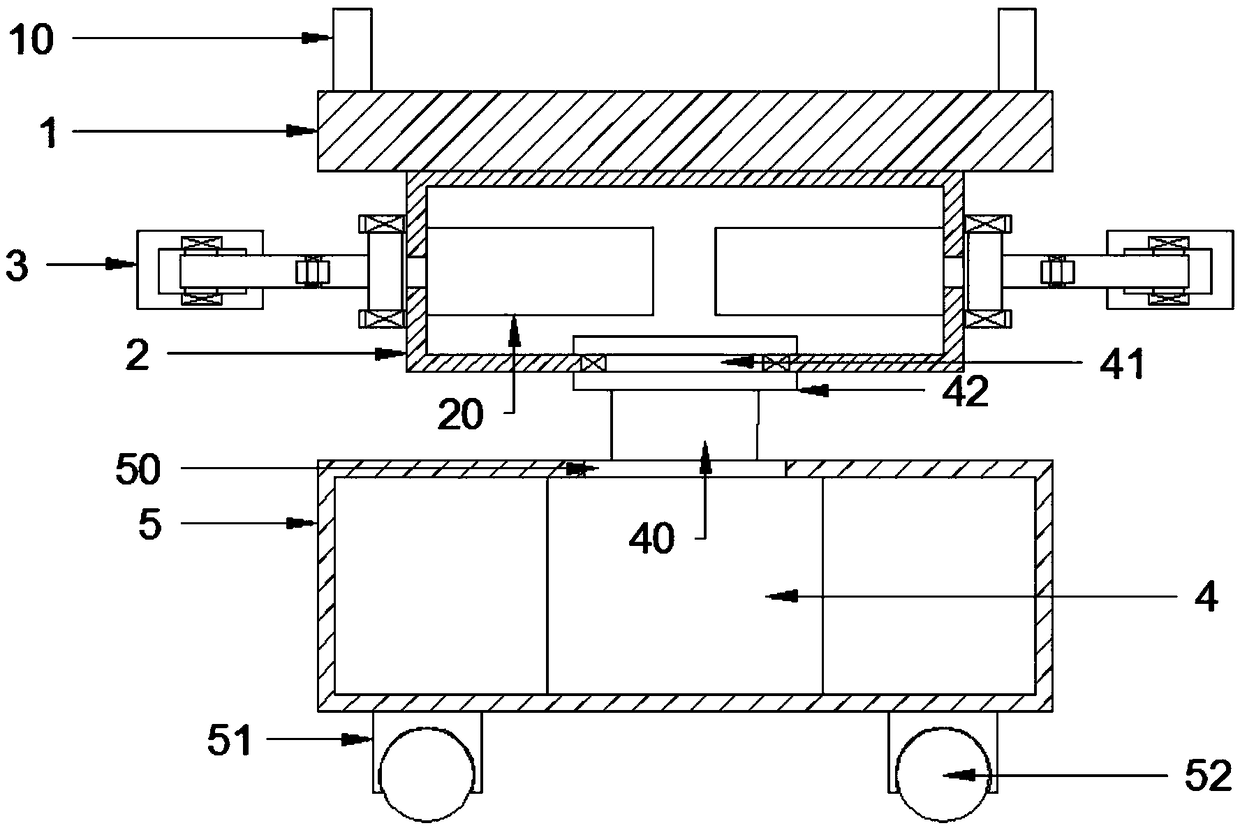

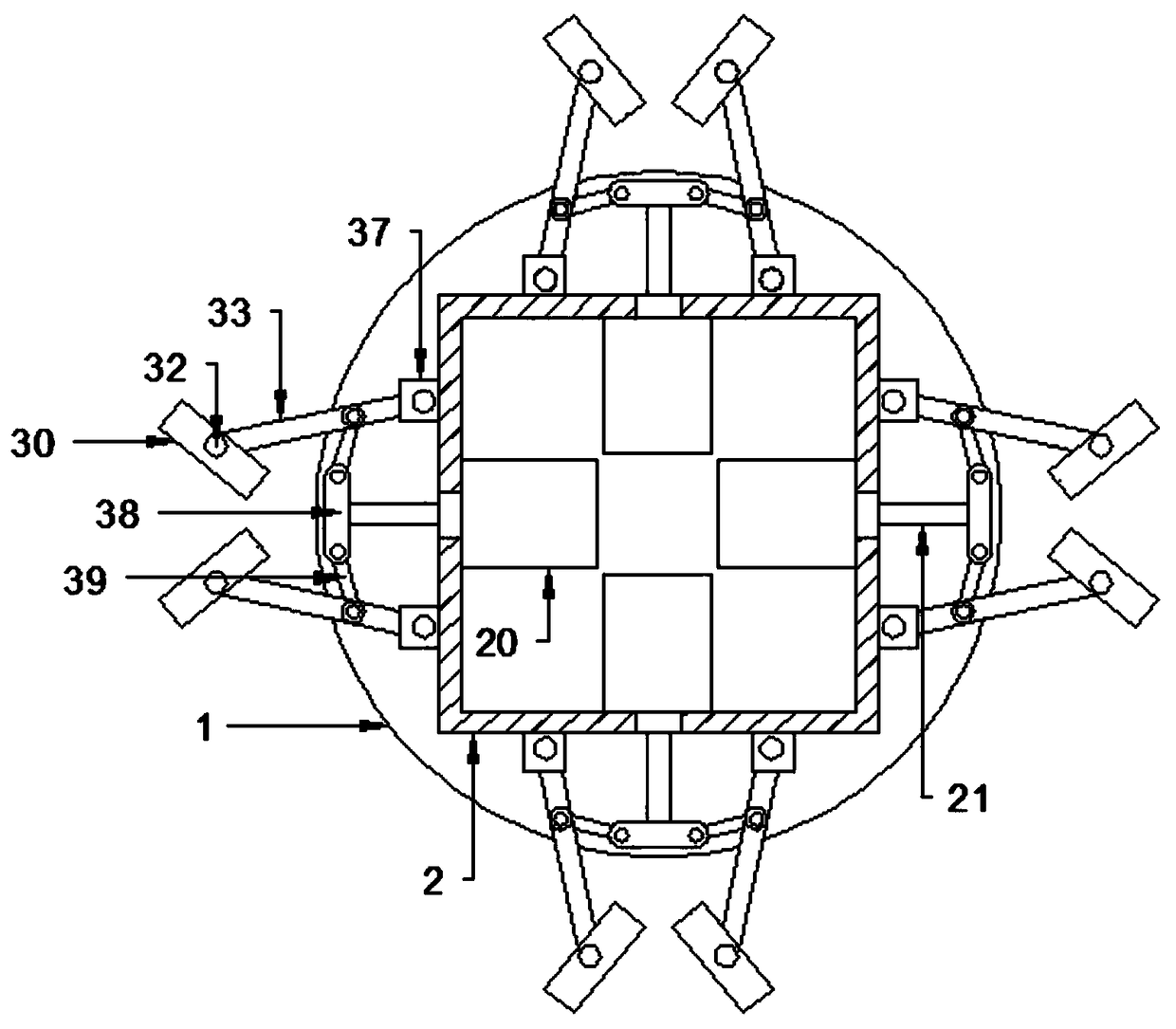

[0022] see Figure 1~4 , in an embodiment of the present invention, a multi-stage cylinder-type intelligent manipulator includes a top plate 1, a rotating cylinder box 2, a manipulator 3, a lifting cylinder 4, and a lifting box 5. The bottom of the top plate 1 is provided with a rotating cylinder box 2. The top plate 1 is a metal circular plate, and a plurality of handrails 10 are fixed on the top surface of the top plate 1. The rotating cylinder box 2 is provided with a plurality of clamping cylinders 20, and the driving end of the clamping cylinder 20 is fixed. Hold the telescopic rod 21, the outer end of the clamped telescopic rod 21 is connected with the manipulator 3, the bottom of the rotating cylinder box 2 is provided with a lift box 5, and the lift box 5 is provided with a lifting device and a travel device;

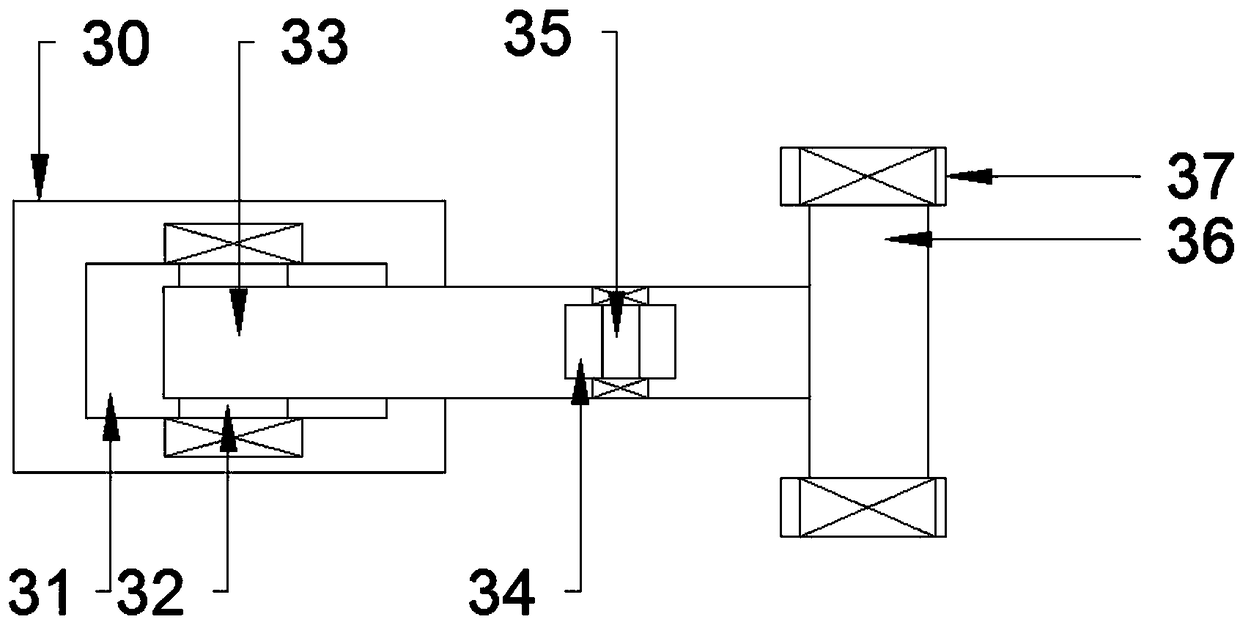

[0023] The manipulator 3 includes a movable splint 30, a main clamping rod 33, a connecting rod 38 and a driving block 39. The connecting rod 38 is fixedly conn...

Embodiment 2

[0032] see Figure 1~4 , in an embodiment of the present invention, a multi-stage cylinder-type intelligent manipulator includes a top plate 1, a rotating cylinder box 2, a manipulator 3, a lifting cylinder 4, and a lifting box 5. The bottom of the top plate 1 is provided with a rotating cylinder box 2. A plurality of handrails 10 are fixed on the top surface of the top plate 1, and a plurality of clamping cylinders 20 are provided on the rotating cylinder box 2, and the driving end of the clamping cylinder 20 is fixed to clamp a telescopic rod 21. The manipulator 3 is connected to the outer end of the clamping telescopic rod 21, and the bottom of the rotating cylinder box 2 is provided with a lifting box 5, and a lifting device and a stroke device are arranged in the lifting box 5;

[0033]The manipulator 3 includes a movable splint 30, a main clamping rod 33, a connecting rod 38 and a driving block 39. The connecting rod 38 is fixedly connected with the clamping cylinder 20,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com