High-temperature-resistant salt-resistant water loss reducer and preparation method and application thereof

A fluid loss agent, high temperature resistant technology, applied in the field of oil and gas cementing, can solve the problems of accelerated hydrolysis of alkaline cement slurry, excessive retardation of cement slurry, and poor high temperature resistance, so as to protect oil and gas layers and reduce pores. The effect of size, strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

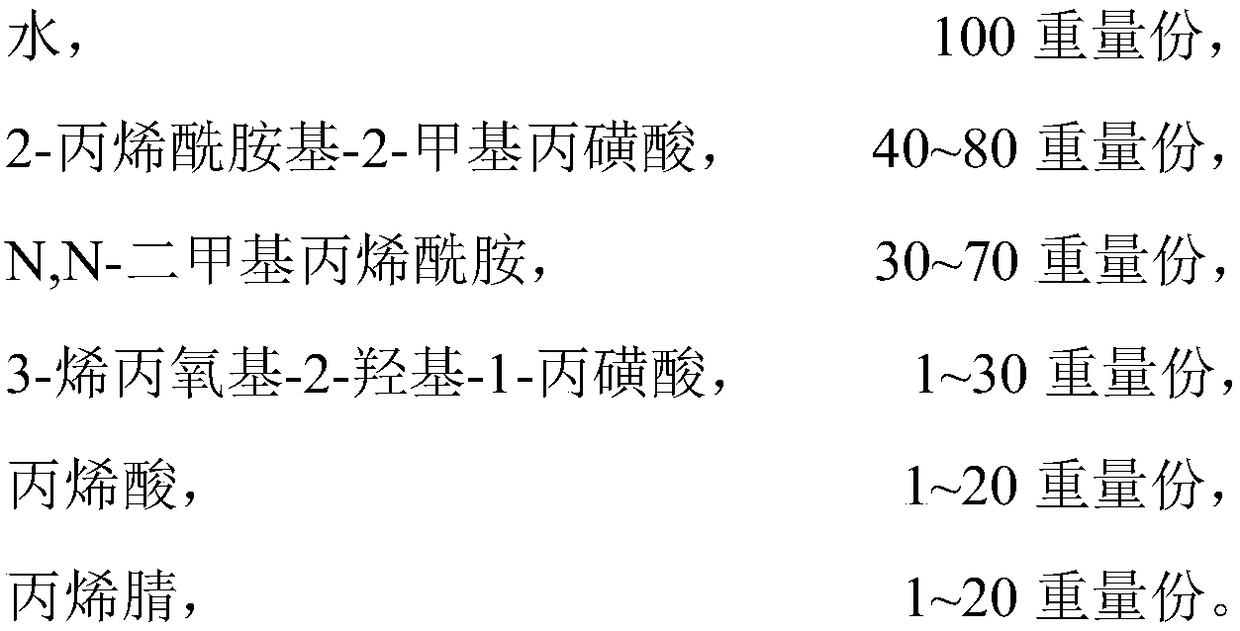

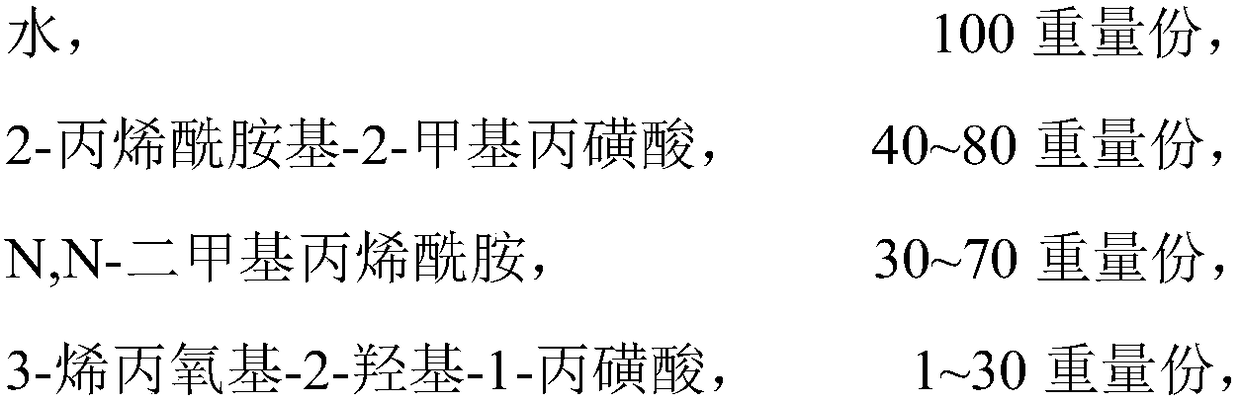

[0032] Weigh 40 parts by weight of 2-acrylamido-2-methylpropanesulfonic acid (AMPS), 30 parts by weight of N,N'-dimethylacrylamide (DMAA), 1 part by weight of acrylic acid (AA), 1 part by weight Parts of 3-allyloxy-2-hydroxy-1-propanesulfonic acid (AHPS), 1 part by weight of acrylonitrile (AN), dissolved in 100 parts by weight of deionized water. The pH value was adjusted to 7 by adding a 40% sodium hydroxide solution. Add the solution into the reactor, put the reactor in a constant temperature water bath at 60°C for 1 to 1.5 hours; feed nitrogen into the reactor to remove oxygen, and when the temperature of the aqueous solution in the reactor reaches 60°C, add 0.1 parts by weight Potassium persulfate and 0.1 parts by weight of sodium bisulfite initiate the reaction, the reaction lasts for 3 hours, and naturally cool to room temperature to make a pentapolymer solution, which is the anti-high temperature and anti-salt fluid loss reducing agent of the present invention, code-nam...

Embodiment 2

[0034] Except that the difference from Example 1 is: the amount of 2-acrylamido-2-methylpropanesulfonic acid (AMPS) is changed to 80 parts by weight, and the amount of N,N-dimethylacrylamide (DMAA) Change to 70 parts by weight, change the consumption of acrylic acid (AA) into 20 parts by weight, change the consumption of 3-allyloxy-2-hydroxyl-1-propanesulfonic acid (AHPS) into 30 parts by weight, change the consumption of acrylonitrile The consumption of (AN) is changed into 20 parts by weight. Example 2 Compared with Example 1, other operating methods are the same, and an oil well cement fluid loss reducer (pentapolymer) is prepared, code-named Sample 2.

Embodiment 3

[0036] Except that the difference is that the amount of acrylic acid (AA) is changed to 20 parts by weight, compared with Example 1 in Example 3, the weight ratios and operating methods of other components are the same, and the oil well cement fluid loss reducer is prepared. (pentapolymer), the code name is sample 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap