Production method of 6063 aluminium alloy section

A technology of aluminum alloy profiles and production methods, which is applied in the field of aluminum alloy materials, can solve problems such as fluctuations in performance differences, uncontrollable comprehensive properties of profiles, etc., and achieve the effect of excellent comprehensive mechanical properties and good composition uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

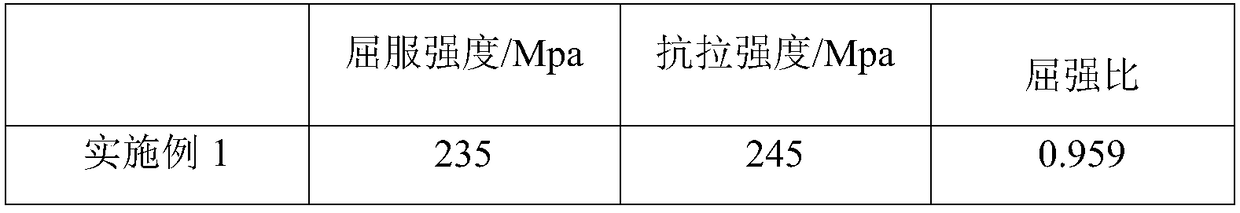

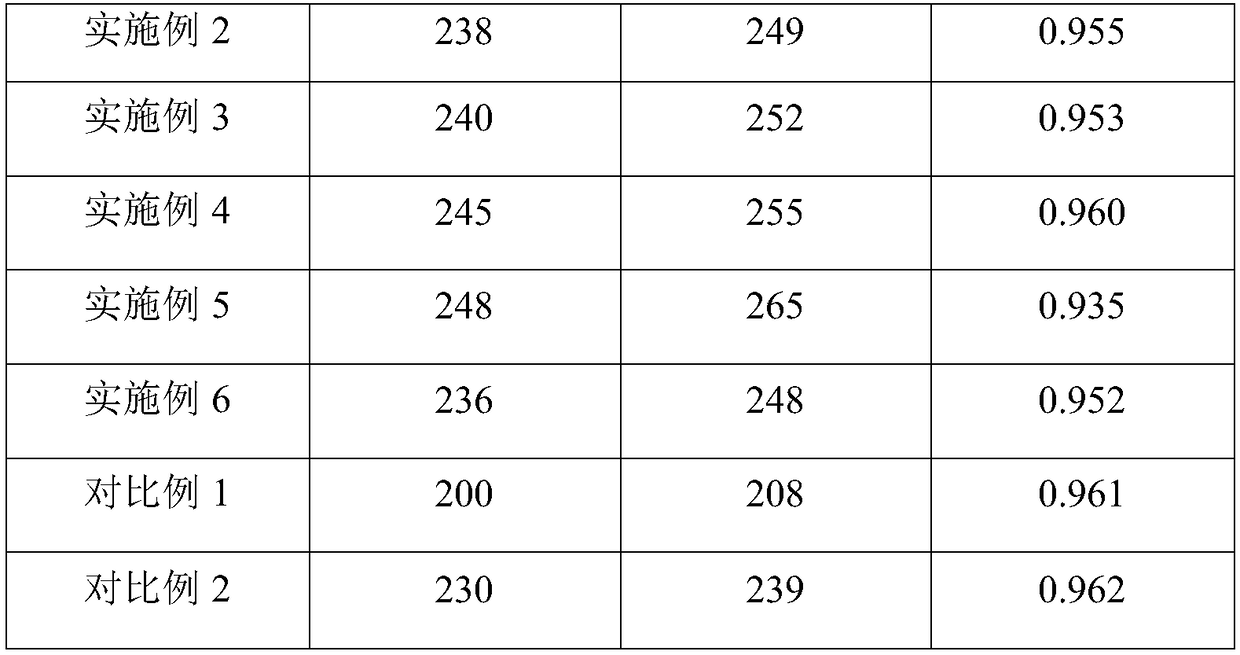

Examples

Embodiment 1

[0016] The present embodiment provides a kind of production method of 6063 aluminum alloy profile, and it comprises the following steps:

[0017] (a) Heat the aluminum alloy ingot to 400°C and keep it warm for 2 hours; the aluminum alloy ingot includes the following components in mass percentage, Si: 0.53%, Fe: 0.15%, Cu: 0.16%, Mn: 0.04%, Mg: 0.92%, Cr: 0.06%, Zn: 0.04% and Ti: 0.04%, the balance is Al and unavoidable impurities;

[0018] (b) heating the extrusion die to a temperature higher than that of the aluminum alloy ingot (usually about 20°C higher than the temperature of the aluminum alloy ingot), and keeping it warm;

[0019] (c) extruding the aluminum alloy ingot so that it passes through an extrusion die at a speed of 1 to 1.5 cm / min to obtain an aluminum alloy profile;

[0020] (d) Heat the aluminum alloy profile to 515°C, keep it warm for 120 minutes, and then carry out water cooling in the quenching zone (water temperature is 60-80°C); then keep it at 170°C for...

Embodiment 2

[0022] This embodiment provides a production method of 6063 aluminum alloy profiles, which is basically the same as that in Embodiment 1, except that the aluminum alloy ingot includes the following components in mass percentages, Si: 0.57%, Fe: 0.15%, Cu: 0.20%, Mn: 0.04%, Mg: 0.88%, Cr: 0.10%, Zn: 0.04%, and Ti: 0.04%, and the balance is Al and unavoidable impurities.

Embodiment 3

[0024] This embodiment provides a production method of 6063 aluminum alloy profiles, which is basically the same as that in Embodiment 1, except that the aluminum alloy ingot includes the following components in mass percentage, Si: 0.54%, Fe: 0.13%, Cu: 0.17%, Mn: 0.03%, Mg: 0.89%, Cr: 0.07%, Zn: 0.03%, and Ti: 0.03%, and the balance is Al and unavoidable impurities.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com